Method for preparing high-purity gadolinium through refining and removing aluminum in rare earth gadolinium solution by ionic liquid method

An ionic liquid, rare earth technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

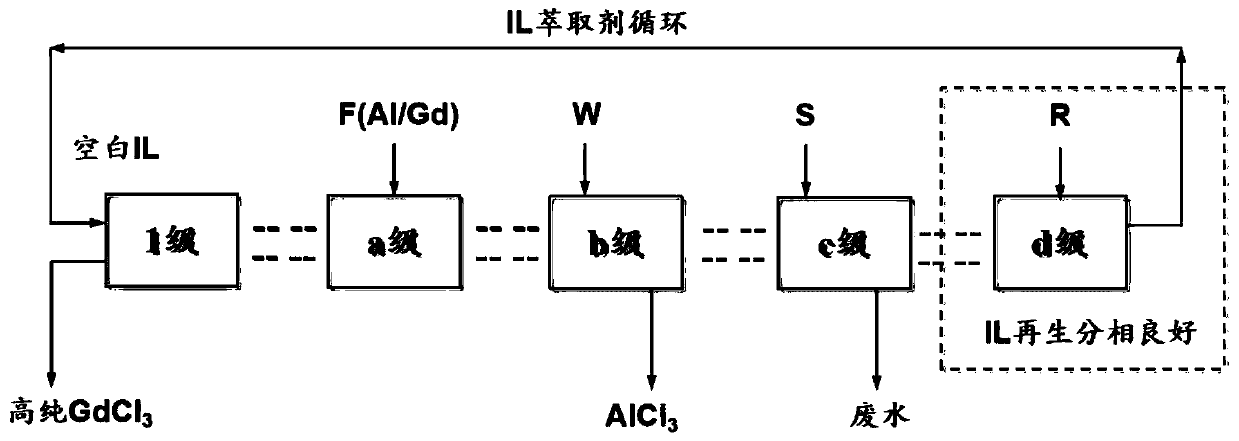

Image

Examples

Embodiment 1

[0023] In the extraction tank with a volume ratio of mixing chamber and clarification chamber of 1:3, set the mixing time for 5 minutes, and use GdCl with a concentration of 1.0mol / L as the raw material 3 Solution, aluminum content 600ppm, with 0.1mol / L [N1888][CA12] kerosene solution as extraction agent, with 1mol / L dilute hydrochloric acid as washing solution, 2.0mol / L hydrochloric acid as stripping agent, process flow ratio control is 0 : F: W: S = 10: 100: 10: 20, IL regeneration agent with water: concentrated ammonia water volume ratio 5: 60, 2-stage IL regeneration, continuous operation to obtain GdCl 3 Solution aluminum content 10ppm, GdCl 3 Yield 99.9%.

Embodiment 2

[0025] In the extraction tank with a volume ratio of 1:4 between the mixing chamber and the clarification chamber, the mixing time is set to 6 minutes, and the raw material is GdCl with a concentration of 1.2mol / L. 3 Solution, aluminum content 1500ppm, with 0.2mol / L [N1888] [NA]

[0026] Kerosene + octanol solution is used as extraction agent, 0.5mol / L dilute hydrochloric acid is used as washing solution, 4.0mol / L hydrochloric acid is used as stripping agent, and the process flow ratio is controlled as O:F:W:S=20:150:20:40 , water: concentrated ammonia water volume ratio of 10:60 IL regeneration agent, 2-stage IL regeneration, continuous operation to obtain GdCl 3 Solution aluminum content 9ppm, GdCl 3 Yield 99.9%.

Embodiment 3

[0028] In the extraction tank with a volume ratio of 1:3 between the mixing chamber and the clarification chamber, set the mixing time for 5 minutes, and use GdCl with a concentration of 1.5mol / L as the raw material. 3 Solution, aluminum content 2000ppm, use 0.6mol / L [N7777][oleate] and a mixed solution of kerosene and octanol as the extractant, use 1.5mol / L dilute hydrochloric acid as the washing solution, and 3.0mol / L hydrochloric acid as the stripping agent, The process flow ratio is controlled as O: F: W: S = 30: 250: 30: 60, water: concentrated liquid alkali volume ratio of 10: 80 IL regeneration agent, 3-stage IL regeneration, continuous operation to obtain GdCl 3 Solution aluminum content 10ppm, GdCl 3 Yield 99.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com