Method for extracting tea polysaccharide from tea residues

A tea polysaccharide and tea dregs technology, which is applied in the direction of anti-toxic agents and drug combinations, can solve the problems of low extraction rate, low extraction efficiency, and short extraction time, and achieve improved wall-breaking efficiency, extraction efficiency, and extraction speed , the effect of improving the yield and antioxidant activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

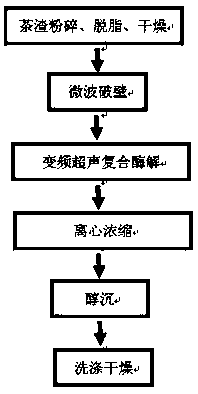

Image

Examples

Embodiment 1

[0048] Crush the tea residue, pass through a 100-mesh sieve, degrease with absolute ethanol, wash the tea residue powder at 75°C for 30 minutes, centrifuge at 2000r / min for 10 minutes, remove the supernatant, and dry it at 40°C and 50MPa Dry under vacuum for 30 minutes to obtain fine powder of tea residue; add water to the tea residue powder according to the ratio of material to liquid of 1:35, control the water temperature to 70°C, set the microwave power to 500 W, and break the wall by microwave for 80 minutes; according to the ratio of 1:1 Add cellulase and pectinase with a mass ratio of 0.1% of the solution mass, adjust the solution temperature to 45°C, set the pH value to 6.5, set the ultrasonic frequency to 35KHz, low-frequency enzymatic hydrolysis for 50min, adjust the solution temperature to 65°C, and set the ultrasonic frequency to 60KHz, high-frequency enzymatic hydrolysis for 40 minutes; inactivate the solution at 110°C for 15 minutes, put it in a centrifuge and cent...

Embodiment 2

[0050] Crush the tea residue, pass through a 150-mesh sieve, degrease with absolute ethanol, wash the tea residue powder at 75°C for 40 minutes, centrifuge at a speed of 2000r / min for 10 minutes, remove the supernatant, and dry it at 40°C and 50MPa Dry under vacuum for 30 minutes to obtain tea residue fine powder; add water to the tea residue powder according to the ratio of material to liquid at 1:40, control the water temperature at 75°C, set the microwave power to 550 W, and microwave the wall breaking for 70 minutes; according to the ratio of 1:1.5 Add cellulase and pectinase with a mass ratio of 0.15% of the solution mass, adjust the solution temperature to 50°C, and set the pH value to 6.6. 65KHz, high-frequency enzymatic hydrolysis for 35 minutes; inactivate the solution at 115°C for 12 minutes, put it in a centrifuge and centrifuge at a speed of 3300r / min for 11 minutes, remove the residue after vacuum filtration, and place the filtrate in a rotary evaporator. Concentr...

Embodiment 3

[0052] Crush the tea residue, pass through a 200-mesh sieve, degrease with absolute ethanol, wash the tea residue powder at 75°C for 50 minutes, centrifuge at 2000r / min for 10 minutes, remove the supernatant, and dry it at 40°C and 50MPa Dry under vacuum for 30 minutes to obtain tea residue fine powder; add water to the tea residue powder according to the material-liquid ratio of 1:45, control the water temperature at 80°C, set the microwave power to 600 W, and microwave the wall breaking for 60 minutes; according to the ratio of 1:2 Add cellulase and pectinase with a mass ratio of 0.2% of the solution mass, adjust the solution temperature to 55°C, set the pH value to 6.8, set the ultrasonic frequency to 45KHz, low-frequency enzymatic hydrolysis for 40min, adjust the solution temperature to 75°C, and set the ultrasonic frequency to 70KHz, high-frequency enzymatic hydrolysis for 30min; inactivate the solution at 120°C for 10min, put it in a centrifuge and centrifuge at a speed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com