A curing agent for making bricks after water-based drilling cuttings are cured and its preparation method and application

A technology of curing agent and drilling cuttings, which is applied in the field of curing agent and its preparation for brick making after water-based drilling cuttings are solidified. It can solve the problems of excessive moisture content, cracking of bricks, and bonding of raw materials, so as to speed up the reduction and reduce adsorption. Effect of saving water and heat demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

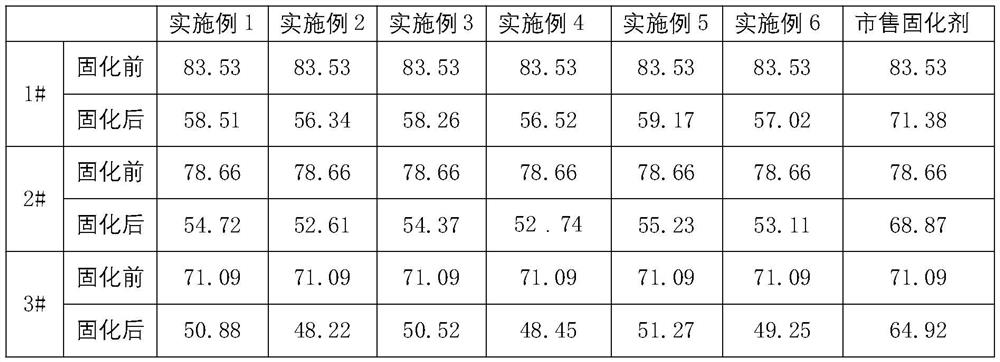

[0038] Embodiment 1: The solidifying agent for making bricks after the solidification of water-based drill cuttings is composed of 5% sodium dodecylsulfonate, 45% coal gangue, 7% sawdust, 40% double fast cement, and 3% sodium chloride Composition, first crush the coal gangue to less than 3mm, dry, control the moisture content <5%, and obtain the product G1; then sieve the sawdust, further pulverize the powder larger than 3mm, mix with the sieved powder, dry, control the moisture content <5% %, to obtain product G2; respectively mix sodium chloride with Shuangkuai cement, G1 and G2, and mix uniformly to obtain products G3 and G4; add sodium dodecylsulfonate to G4, and mix uniformly to obtain product G5 ; Mix G3 and G5 to obtain the target product.

Embodiment 2

[0039] Embodiment 2: the solidifying agent for making bricks after water-based drilling cuttings is solidified consists of 2% sodium dodecyl sulfonate, 40% coal gangue, 5% sawdust, 50% double fast cement, 3% sodium chloride Composition, first crush the coal gangue to less than 3mm, dry, control the moisture content <5%, and obtain product G1; then sieve the sawdust, further pulverize the powder larger than 3mm, mix with the sieved powder, dry, control the moisture content <5% %, to obtain product G2; respectively mix sodium chloride with Shuangkuai cement, G1 and G2, and mix uniformly to obtain products G3 and G4; add sodium dodecylsulfonate to G4, and mix uniformly to obtain product G5 ; Mix G3 and G5 to obtain the target product.

Embodiment 3

[0040] Embodiment 3: the solidifying agent for making bricks after the solidification of water-based drill cuttings is composed of 5% sodium dodecyl sulfonate, 40% coal gangue, 10% sawdust, 40% double fast cement, and 5% aluminum chloride Composition, first crush the coal gangue to less than 3mm, dry, control the moisture content <5%, and obtain product G1; then sieve the sawdust, further pulverize the powder larger than 3mm, mix with the sieved powder, dry, control the moisture content <5% %, to obtain product G2; respectively mix aluminum chloride with Shuangkuai cement, G1 and G2, and mix uniformly to obtain products G3 and G4; add sodium dodecylsulfonate to G4, and mix uniformly to obtain product G5 ; Mix G3 and G5 to obtain the target product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com