Medical sterilizing packaging material capable of efficiently sterilizing

A packaging material and medical technology, applied in the field of high-efficiency sterilization medical sterilization packaging materials, can solve the problems of recycling paper-plastic composite materials, shorten the analysis time, reduce the adsorption of EO or formaldehyde vapor, etc. The effect of good air permeability and good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

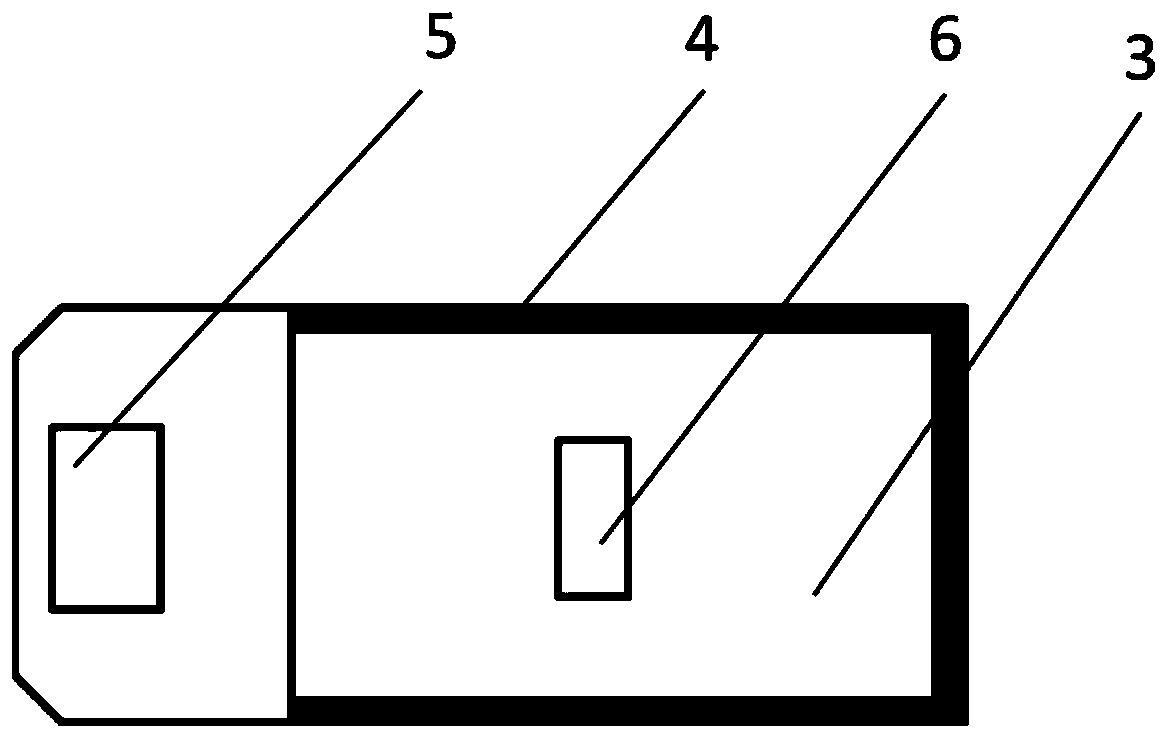

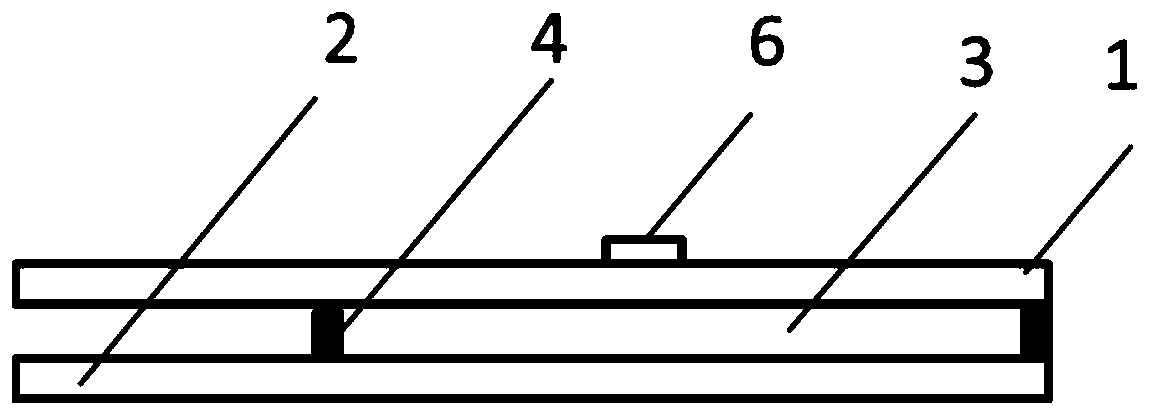

[0079] A single-layer polypropylene porous film with a thickness of 120 μm and a porosity of 75% was prepared by the melt stretching method, and it was used as the upper layer 1 and the lower layer 2 of the medical sterilization packaging material at the same time, and the two were sealed by heat sealing. Connect to obtain the airtight cavity 3. The lower layer 2 is provided with a rectangular hole, and the upper layer 1 is provided with an EO sterilization indicator mark 6 . Some polypropylene porous films were selected to measure air permeability, porosity, tensile strength, puncture strength, average pore size and melting point. The results are shown in Table 1.

Embodiment 2

[0081] A three-layer polypropylene porous film with a thickness of 20 μm (total thickness) and a total porosity of 45% is prepared by a melt stretching method, which is used as the upper layer 1 and the lower layer 2 of the medical sterilization packaging material at the same time, and is sealed by heat sealing. The two are connected by means of a closed cavity 3 . The lower layer 2 is provided with a rectangular hole 5 , and the upper layer 1 is provided with an EO sterilization indicator mark 6 . Some three-layer polypropylene porous films were selected for measurement of air permeability, porosity, average pore size, tensile strength, puncture strength and melting point. The results are shown in Table 1.

Embodiment 3

[0083] A polypropylene / polyethylene / polypropylene porous composite film with a thickness of 12 μm (total thickness) and a total porosity of 60% is prepared by a melt stretching method, which is used as the upper layer 1 and the lower layer 2 of the medical sterilization packaging material at the same time, The two are connected by means of heat sealing to obtain an airtight cavity 3 . The lower layer 2 is provided with a rectangular hole 5 , and the upper layer 1 is provided with an EO sterilization indicator mark 6 . Some polypropylene / polyethylene / polypropylene porous composite films were selected to measure air permeability, porosity, average pore size, tensile strength, puncture strength and melting point. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com