Method for flotation separation of iron oxide ore in cassiterite sulphide slime ore by using combined inhibitor

A technology for combining inhibitors and iron oxide ore, which is applied to the inhibitor of iron oxide minerals in the flotation of high-iron cassiterite sulfide slime, and the field of combined inhibitors of mineral flotation, which can solve the removal/inhibition of iron oxide minerals. Problems such as poor effect, to achieve the effect of concentrate treatment, low dosage and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

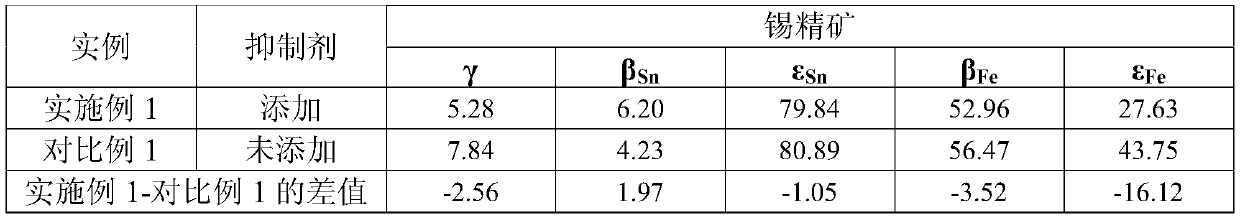

Embodiment 1

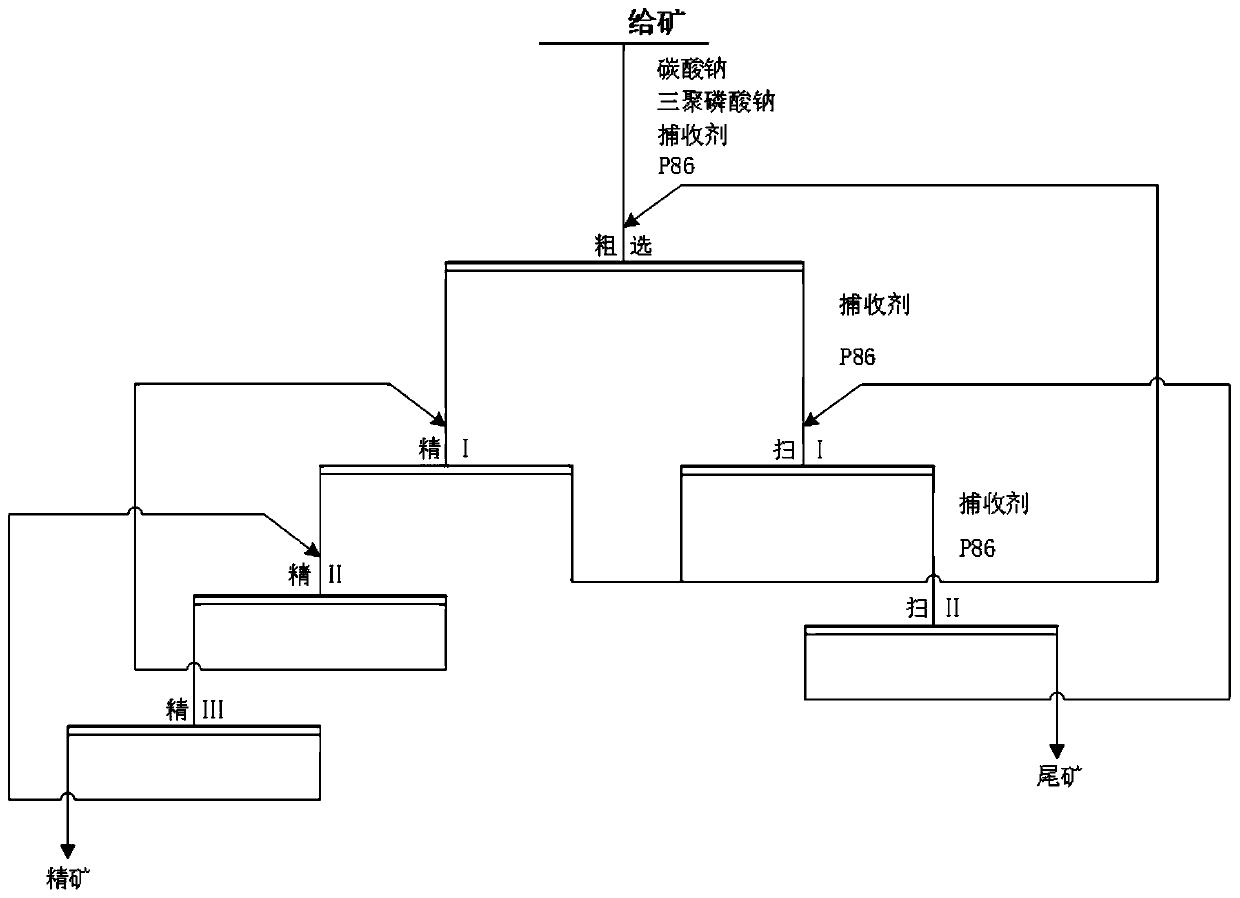

[0018] The method of separating iron oxide ore from cassiterite sulfide ore mud ore by combined inhibitor flotation, the material processed in this embodiment is the cassiterite sulfide ore mud ore gravity separation operation of a certain dressing plant in Yunnan after desliming and desulfurization of the mud ore , Slime materials with -10μm particle size content figure 1 As shown, the flotation separation method is as follows:

[0019] (1) Sodium carbonate is added into water at room temperature, fully stirred for 2-5 minutes, and prepared into a sodium carbonate solution with a mass concentration of 5% for use; at room temperature, sodium tripolyphosphate is added into water, fully stirred for 2-5 minutes, and prepared into a mass concentration 0.5% sodium tripolyphosphate solution is ready for use; salicylic hydroxamic acid is used as a collector, and salicylic hydroxamic acid and 20% of its mass of solid sodium carbonate are added to hot water at 80°C-100°C, fully stirred ...

Embodiment 2

[0029] The method of separating iron oxide ore from cassiterite sulfide ore mud ore by combined inhibitor flotation, the material processed in this embodiment is the cassiterite sulfide ore mud ore gravity separation operation of a certain dressing plant in Yunnan after desliming and desulfurization of the mud ore , Slime materials with -10μm particle size content <15%, sulfur grade <0.5%. The material contains 0.451% tin and 11.49% iron, and the iron mainly exists in the form of hematite and limonite with a distribution rate of 67.76%. The combination inhibitor is composed of sodium carbonate and sodium tripolyphosphate, and the operation of flotation separation of iron oxide ore in cassiterite sulfide ore slime includes roughing, sweeping and beneficiation of cassiterite sulfide ore in sequence, Including one rough, two sweeps and three fines; the flotation separation method is as follows:

[0030] (1) Sodium carbonate is added into water at room temperature, fully stirred ...

Embodiment 3

[0040] The method of separating iron oxide ore from cassiterite sulfide ore mud ore by combined inhibitor flotation, the material processed in this embodiment is the cassiterite sulfide ore mud ore gravity separation operation of a certain dressing plant in Yunnan after desliming and desulfurization of the mud ore , Slime materials with -10μm particle size content <15%, sulfur grade <0.5%. The material contains 1.09% tin and 9.82% iron, and the iron mainly exists in the form of hematite and limonite, with a distribution rate of 79.63%. The combination inhibitor is composed of sodium carbonate and sodium tripolyphosphate, and the operation of flotation separation of iron oxide ore in cassiterite sulfide ore slime includes roughing, sweeping and beneficiation of cassiterite sulfide ore in sequence, Including one rough, two sweeps and three fines; the flotation separation method is as follows:

[0041] (1) Sodium carbonate is added into water at room temperature, fully stirred f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com