Heat exchanger and gas water heater using heat exchanger

A technology of gas water heaters and heat exchangers, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of increasing structural complexity, processing difficulty and assembly difficulty, and achieve enhanced heat exchange effect and Heat exchange efficiency, compact structure, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

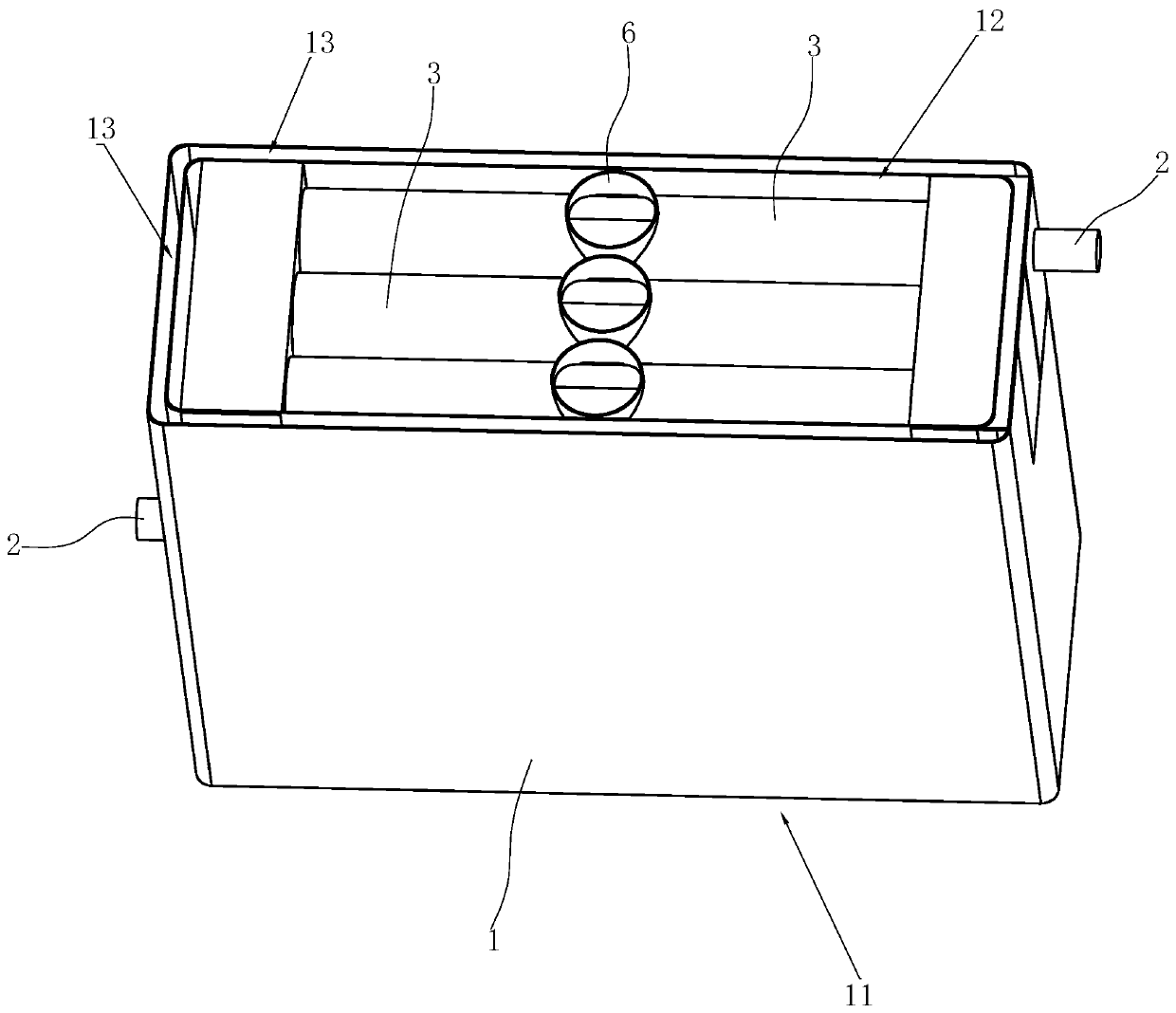

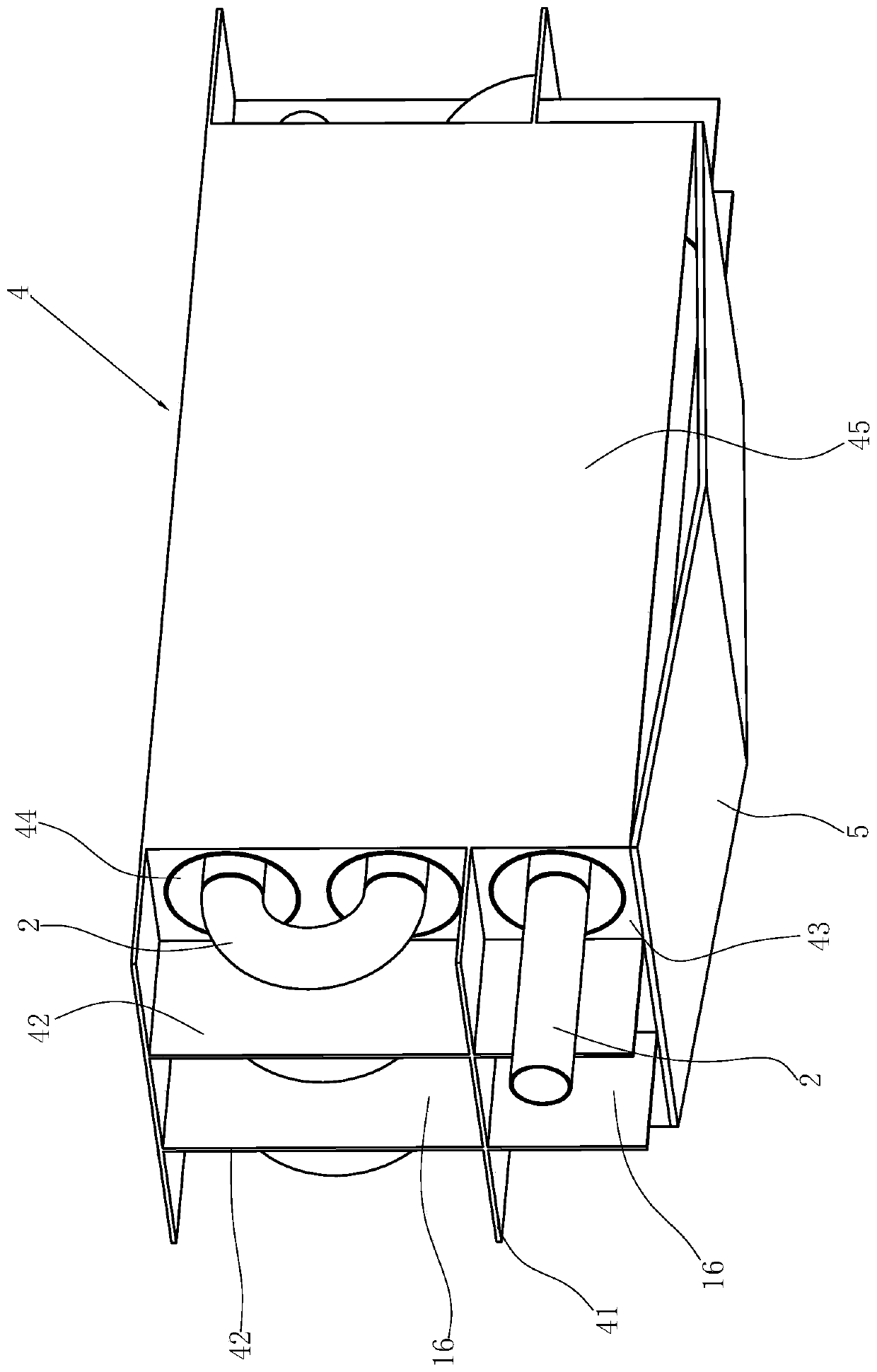

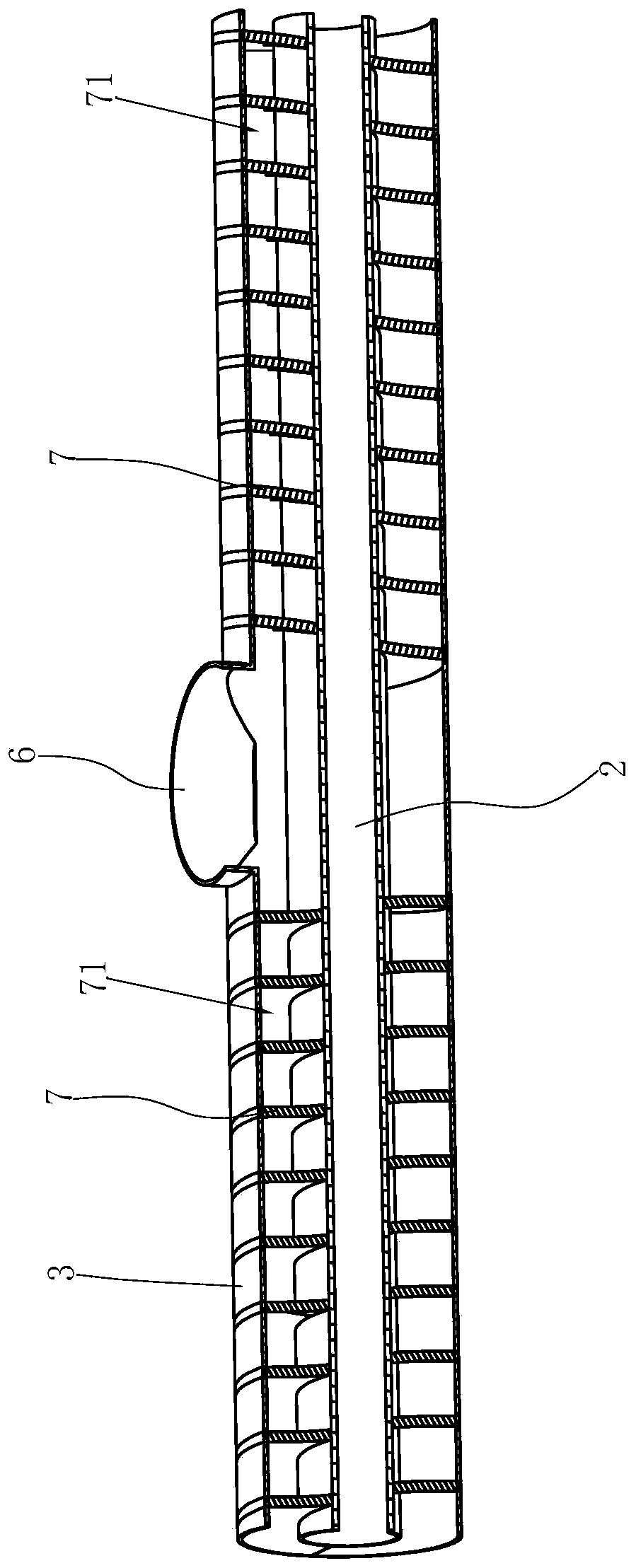

[0029] Such as Figure 1 to Figure 7 As shown, the heat exchanger includes:

[0030] The inner cavity of the shell 1 constitutes a shell side through which the first heat exchange medium circulates. The bottom surface of the shell 1 is provided with a shell inlet 11 , and the top surface of the shell 1 is provided with a shell side outlet 12 . The housing in this embodiment has a double-layer structure, and the interlayer 13 is filled with air; it can also be filled with other heat-insulating materials as required.

[0031] There is one heat exchange tube 2 for the second heat exchange medium to circulate in it to exchange heat with the first heat exchange medium in the casing, which is arranged in each casing 3 in sequence; between the heat exchange tube 2 and the inner wall of the casing There is a gap between them, and the first heat exch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com