Pottery clay sintered water permeable brick

A technology of permeable bricks and clay, applied in the production of clay products, ceramic products, ceramic materials, etc., can solve the problems of easy peeling of the surface of cement bricks, rainwater loss, and pressure resistance, etc., to reduce high-temperature pollution, save heat energy costs, The effect of lowering the firing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

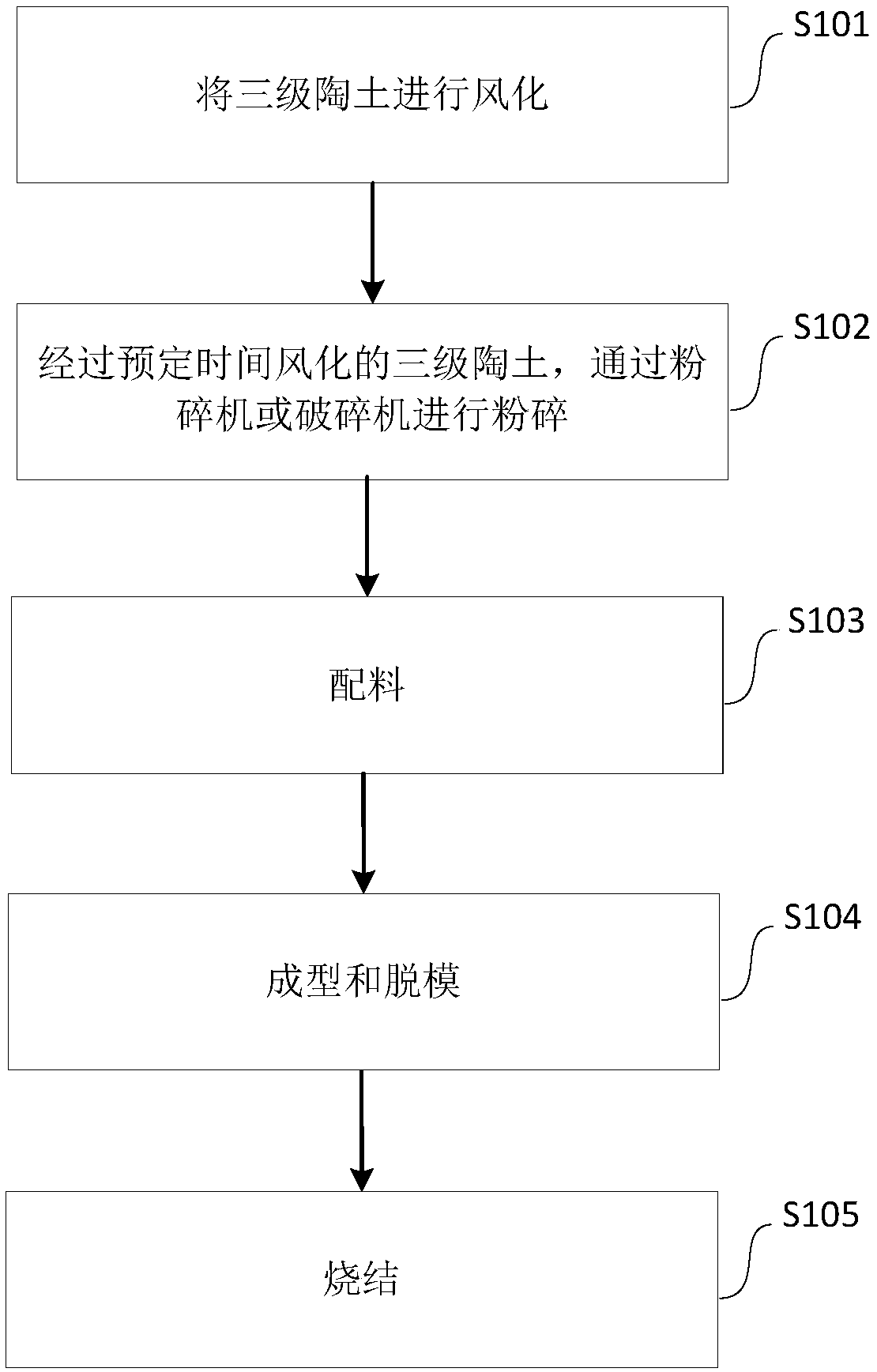

Method used

Image

Examples

Embodiment 1

[0043] The clay sintered seepage brick is composed of the following components in weight percentage: 55% of tertiary clay, 20% of coal gangue, 10% of shale, 14.5% of ironworks waste residue, and 0.5% of barium titanate.

[0044] Table 1. Performance parameters of the clay sintered water seepage brick of embodiment 1

[0045] performance parameters density Compressive strength water absorption frost resistance service life measured value 1.85g / cm 3

[0046] Wherein, the dry mass loss under the frost resistance performance parameter refers to the mass loss amount produced by performing more than 30 freeze-thaw experiments on clay sintered seepage bricks under the set condition of minus 35 degrees Celsius; The service life is calculated according to the loss amount of the dry mass loss reaching the usual standard of the prior art.

Embodiment 2

[0048] The clay sintered seepage brick is composed of the following components in weight percentage: tertiary clay 52%, coal gangue 23%, shale 10%, ironworks waste slag 14.5%, barium titanate 0.5%.

[0049] Table 2. Performance parameters of the clay sintered water seepage brick of embodiment 2

[0050] performance parameters density Compressive strength water absorption frost resistance service life measured value 1.95g / cm 3

Embodiment 3

[0052] The clay sintered water seepage brick is composed of the following components in weight percentage: 50% of tertiary clay, 25% of coal gangue, 10% of shale, 14.5% of ironworks waste residue, and 0.5% of barium titanate.

[0053] Table 3. Performance parameters of the clay sintered water seepage brick of embodiment 3

[0054] performance parameters density Compressive strength water absorption frost resistance service life measured value 1.76g / cm 3

[0055] In order to more clearly reflect the technical advantages of the clay sintered water seepage brick of the present invention, the inventor also conducted a comparative technical parameter test with cement bricks that are often used in the market.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com