Cross-linked polyethylene insulated cable by-product migration collection testing device

A cross-linked polyethylene and insulated cable technology, which is applied in measuring devices, electrical devices, preparation of test samples, etc., can solve the problems of large specific surface area of sheet samples, and achieve the effect of improving efficiency and avoiding error in results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

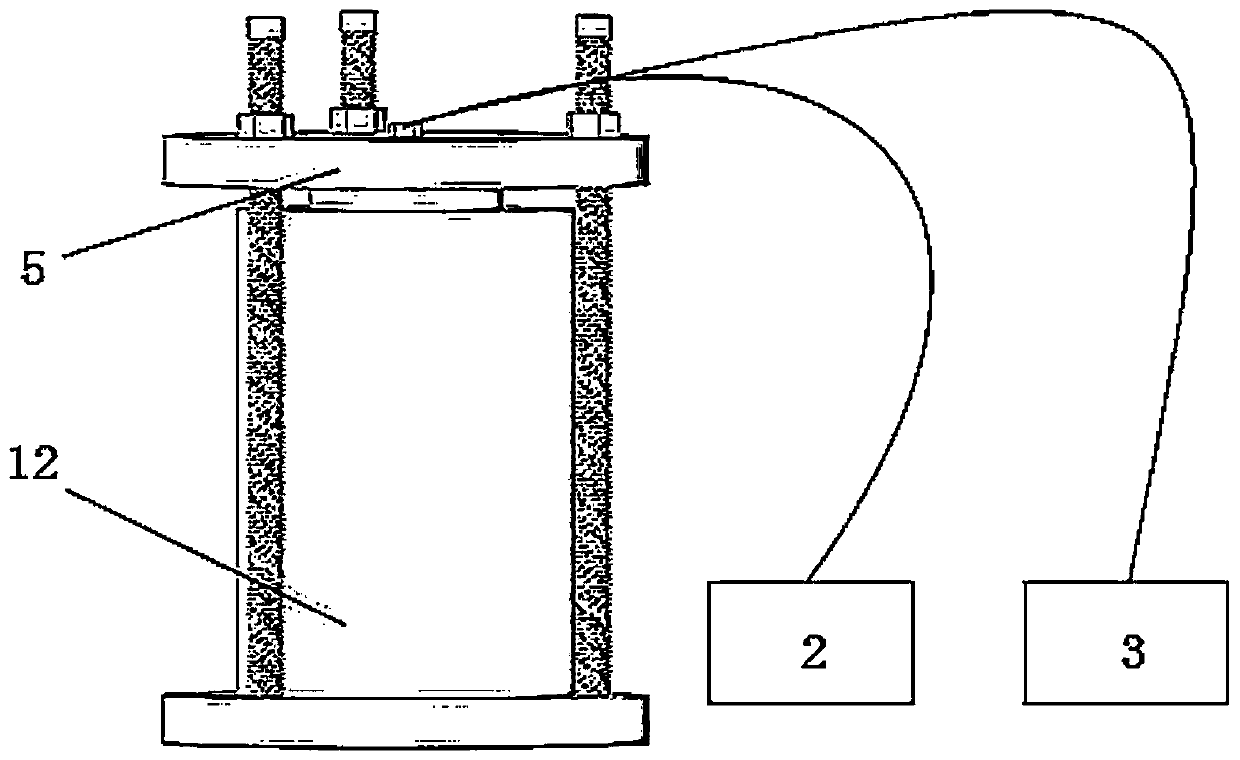

[0025] Such as figure 1 As shown, this embodiment includes: a temperature detection component 2 and a pressure detection component 3 connected to the by-product migration collection component 1 .

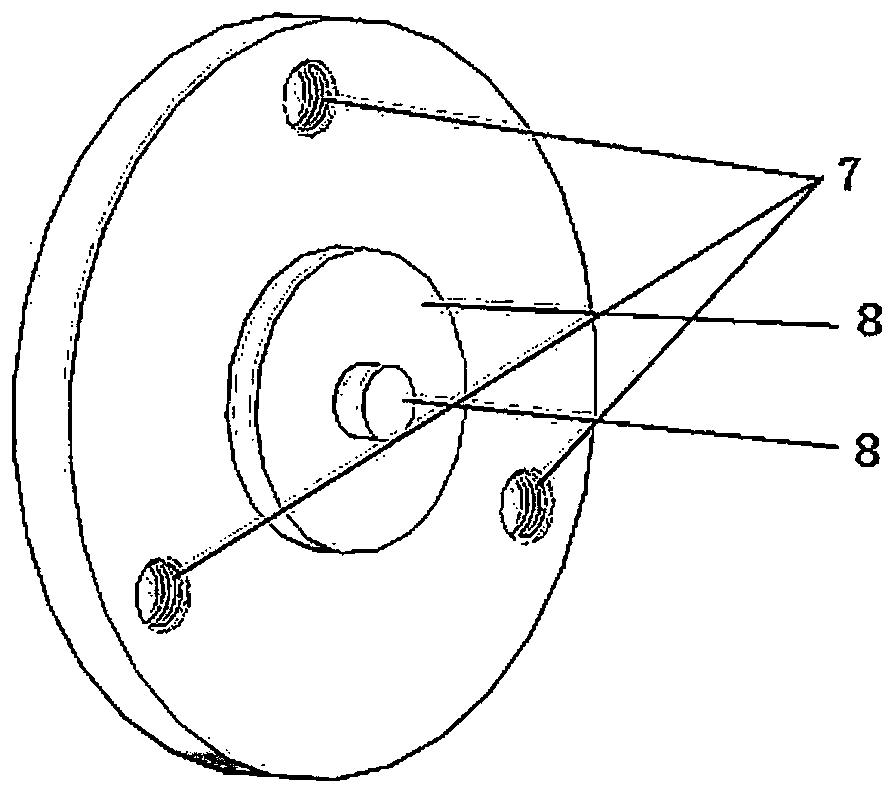

[0026] Such as figure 2 As shown, the by-product migration collection part 1 includes: a support cover 4, a sealing cover 5 and three adjusting bolts 6, wherein: the supporting cover 4 and the sealing cover 5 are connected by three adjusting bolts 6, and the three adjusting bolts 6 are evenly distributed in the screw holes 7 on the circumference of the sealing cover plate 5 and the support cover plate 4.

[0027] Such as image 3 As shown, the diameter of the support cover plate 4 is 200mm, and the height is a circular flat plate of 20mm. Its screw hole is a semi-transparent threaded hole. The edge of the plate 4 is 20 mm and the depth of the screw hole 7 is 10 mm.

[0028] Such as Figure 4 As shown, the size of the sealing cover plate 5 is the same as that of the supporting ...

Embodiment 2

[0040] Compared with embodiment 1, the by-product migration collection part of this embodiment includes: a supporting cover, a sealing cover and an adjusting bolt, wherein: the center of the supporting cover and the sealing cover are connected by an adjusting bolt. support cover see Figure 8 , sealing cover see Figure 9 .

[0041] The joint between the adjusting bolt and the support cover is a semi-transparent threaded hole.

[0042] The connection between the adjusting bolt and the sealing cover is a fully transparent threaded hole.

[0043] Sealing gaskets are provided in the direction where the supporting cover and the sealing cover are in contact with the insulated wire core 12 .

[0044]Sealing passages 14 are provided on both sides of the threaded hole of the sealing cover to facilitate the passage of the temperature detection component and the pressure detection component.

[0045] The device of this embodiment works in the following way: after one end of the adju...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com