Water-based nano coating material, preparation process of micro-crack diagnosis circuit and application of micro-crack diagnosis circuit

A nano-coating and preparation process technology, applied in metal material coating process, coating, anti-corrosion coating and other directions, can solve the problems of formula material processing performance, mechanical properties, laser processing performance decline, affecting the use effect, difficult to operate and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] A water-based nano-coating material, the water-based nano-coating material is composed of a solid phase and a liquid phase according to a mass ratio of 1:1, and the solid phase is composed of the following raw materials: kaolin 35wt%, cobalt blue 15wt%, quartz powder 27wt %, iron red 12wt%, alumina short fiber 5wt%, filler 6wt%; the liquid phase is composed of 55wt% silicon-oxo hybrid and 45wt% PAI; the filler is titanium dioxide.

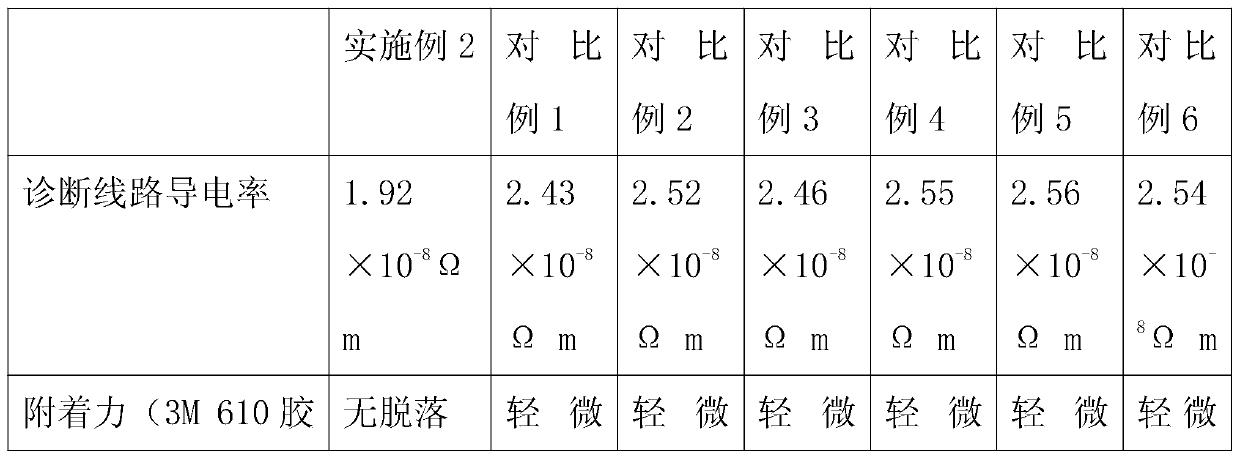

Embodiment 2

[0078] A preparation process of a microcrack diagnostic circuit based on a water-based nano-coating, wherein the water-based nano-coating material is the above-mentioned water-based nano-coating material, and the preparation process of the micro-crack diagnostic circuit comprises the following steps:

[0079] Step 1. According to the proportion, take the water-based nano-coating material, mix the water-based nano-coating material and stir for 8 hours, speed: 30 rpm; temperature: normal temperature;

[0080] Step 2, spraying three layers of water-based nano-coating materials on the workpiece;

[0081] Step 3. Perform laser direct graphic processing on the workpiece after spraying;

[0082] Step 4. Put the workpiece processed in step 3 into the ultrasonic dust removal equipment for 5-15 minutes, drip water for 25 seconds, and carry out in an environment of 55°C;

[0083] Step 5. The workpiece after the ultrasonic treatment is subjected to two washing treatments at room temperat...

Embodiment 3

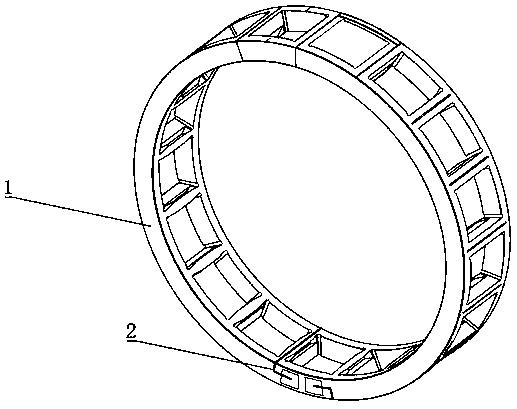

[0126] The above-mentioned application of the preparation process of the microcrack diagnosis circuit based on the water-based nano-coating, the application is the application on the bearing surface; as figure 1 As shown, the bearing is used as the workpiece, and the preparation process of the above-mentioned microcrack diagnostic circuit is adopted, the bearing main body 1, and the diagnostic circuit 2; a high-quality composite deposited metal diagnostic circuit is produced, and its fracture strength is close to the bearing fracture strength, but not greater than that of the bearing body. Breaking strength;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com