Preparation method of nano carbon powder, SBS and rubber powder composite modified asphalt

A technology of compound modified asphalt and nano-carbon powder, which is used in building components, building insulation materials, buildings, etc., can solve problems such as hindering the performance of modified materials, reduce temperature sensitivity, avoid different test processes, and improve high temperature resistance. The effect of deformability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention further describes the present invention in conjunction with specific embodiment:

[0029] A preparation method of nano carbon powder, SBS, rubber powder composite modified asphalt, comprising the following steps:

[0030] 1), prepare raw materials according to mass ratio:

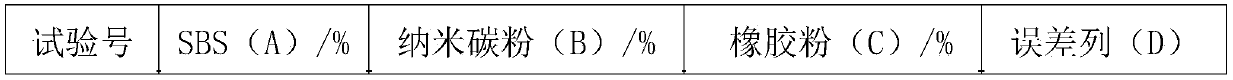

[0031] nano carbon powder 1.0% 1.5% 2.0% rubber powder 12% 15% 18% SBS 0.5% 1.0% 1.5%

[0032] Table 1: Raw materials

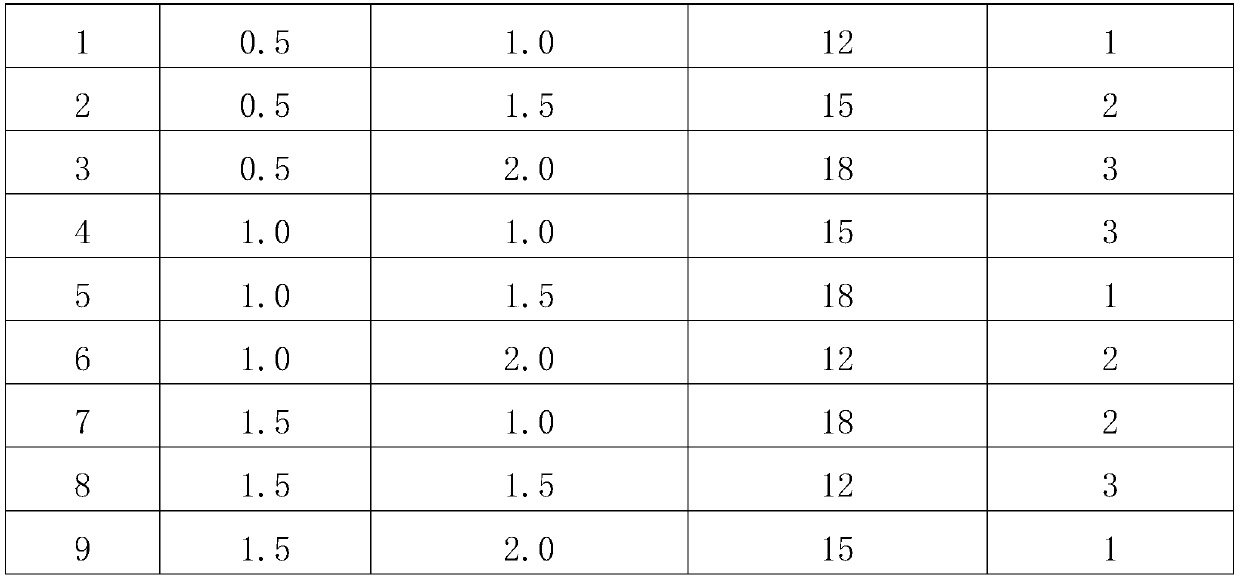

[0033] 2), pass the raw materials in step 1) through the orthogonal test, design 9 sets of test plans, and pass the physical performance test to get the best blending ratio:

[0034]

[0035]

[0036] Table 2: Orthogonal experiment design scheme and influencing factors

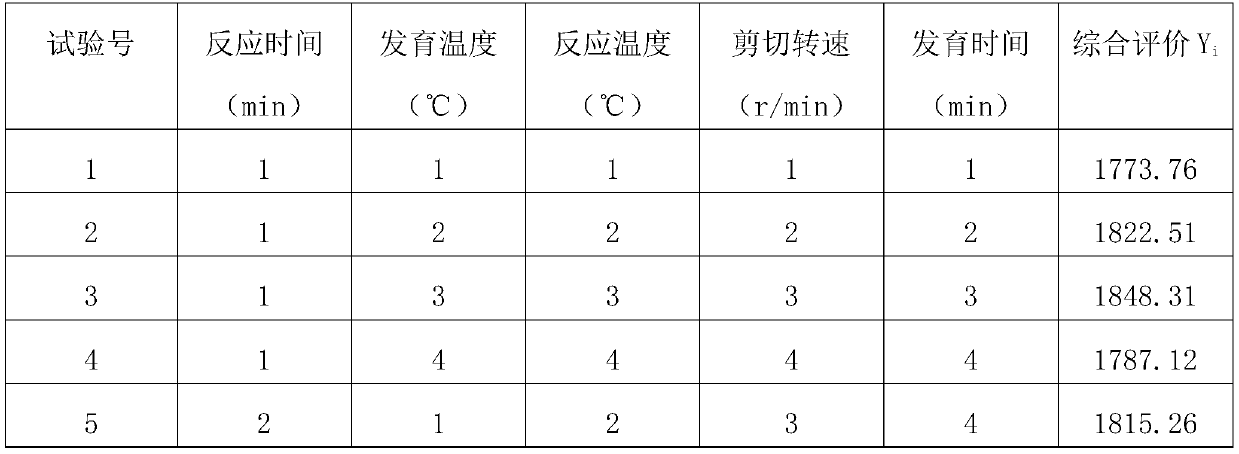

[0037] 3), the modified asphalt under the optimal blending ratio in step 2 is taken as the research object, with shear speed, reaction time, reaction temperature, development time, development temperature as independent variable control factors:

[0038...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com