Alhagi sparsifolia sugar polymer and preparation method and application thereof

A technology of polymer and thorn sugar, applied in the field of medicine, can solve the problems of lack of clear structural features and physical and chemical properties, and achieve the effects of reducing the difficulty of separation and purification, convenient operation and remarkable effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

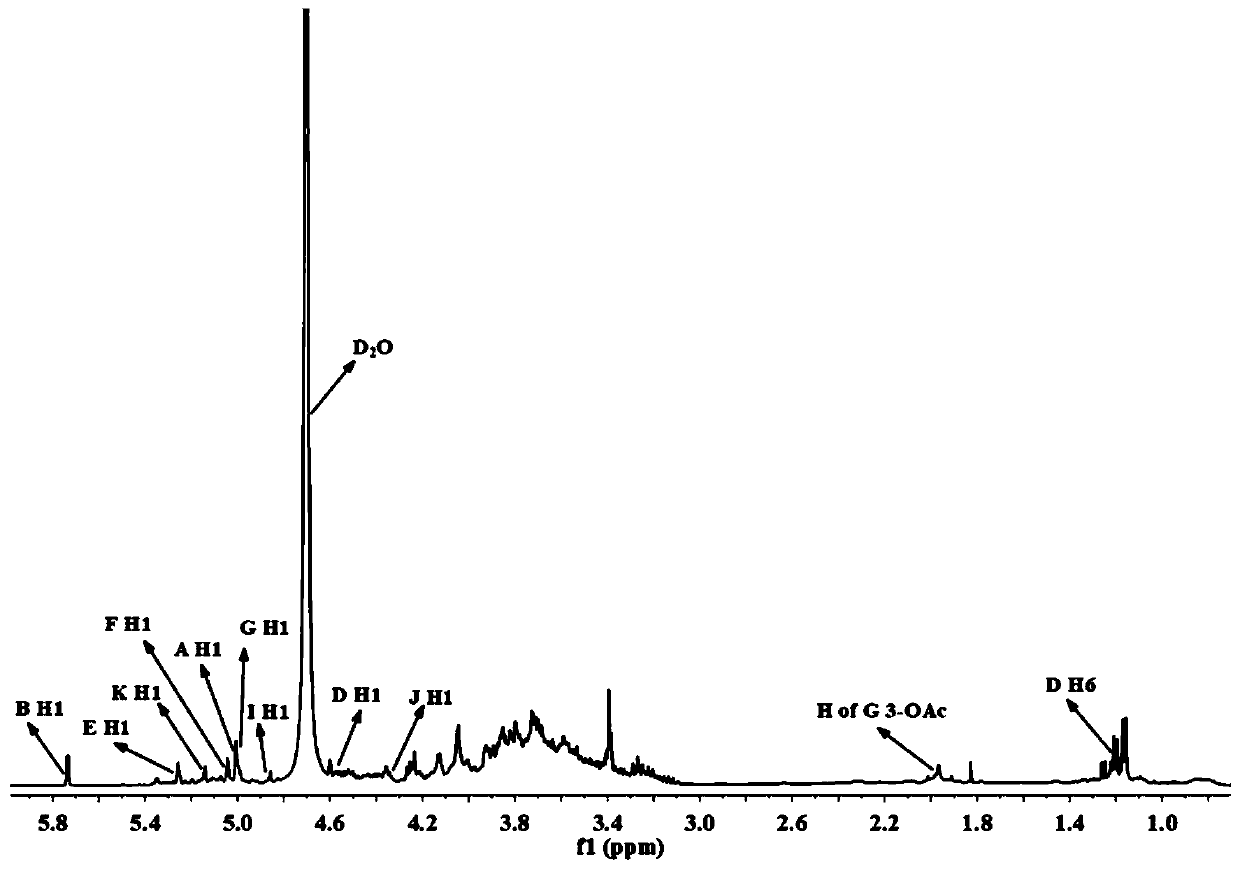

Image

Examples

Embodiment 1

[0052] The camel thorn sugar polymer was prepared according to the following steps:

[0053] 1) Material selection: Soak 30kg of the aboveground part of camel thorn in water for 12 hours;

[0054] 2) Water extraction: extract the aerial part of camel thorn soaked in step 1) with 10 times the volume of hot water (100°C) for 2 hours, and collect the extract;

[0055] 3) Fractional alcohol precipitation: Concentrate the extract obtained in step 2) at 60°C under reduced pressure, add ethanol for alcohol precipitation to make the volume concentration of ethanol 40%, leave it at room temperature for 24 hours, and then centrifuge to obtain supernatant 1 and precipitate 1, Collect the precipitate 1, which is the crude sugar polymer AP1; concentrate the supernatant 1 at 60°C under reduced pressure, add ethanol for alcohol precipitation to make the volume concentration of ethanol 60%, leave it at room temperature for 24 hours, and then centrifuge to obtain the supernatant 2 and precipit...

Embodiment 2

[0062] The camel thorn sugar polymer was prepared according to the following steps:

[0063] 1) Material selection: Soak 30kg of camel thorn in water for 6 hours;

[0064] 2) Water extraction: extract the aboveground part of camel thorn soaked in step 1) with 5 times the volume of hot water (60°C) for 3 hours, collect the extract and residue, and dry the residue;

[0065] 3) Fractional alcohol precipitation: Concentrate the extract obtained in step 2) at 40°C under reduced pressure, add ethanol for alcohol precipitation to make the volume concentration of ethanol 30%, leave it at room temperature for 10 hours, and then centrifuge to obtain supernatant 1 and precipitate 1, Collect the precipitate 1, which is the crude sugar polymer AP1; concentrate the supernatant 1 at 40°C under reduced pressure, add ethanol for alcohol precipitation to make the volume concentration of ethanol 60%, leave it at room temperature for 10 hours, and then centrifuge to obtain the supernatant 2 and p...

Embodiment 3

[0070] The camel thorn sugar polymer was prepared according to the following steps:

[0071] 1) Material selection: Soak 30kg of the aboveground part of camel thorn in water for 10 hours;

[0072] 2) Water extraction: extract the aboveground part of camel thorn soaked in step 1) with 15 times the volume of hot water (90°C) for 10 hours, collect the extract and residue, and dry the residue;

[0073] 3) Fractional alcohol precipitation: Concentrate the extract obtained in step 2) at 70°C under reduced pressure, add ethanol for alcohol precipitation so that the volume concentration of ethanol is 60%, leave it at room temperature for 28 hours, and then centrifuge to obtain supernatant 1 and precipitate 1, Collect the precipitate 1, which is the crude sugar polymer AP1; concentrate the supernatant 1 at 70°C under reduced pressure, add ethanol for alcohol precipitation to make the volume concentration of ethanol 80%, leave it at room temperature for 28 hours, and then centrifuge to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com