A kind of continuous production method of 1,3-dimethyl-2-imidazolinone

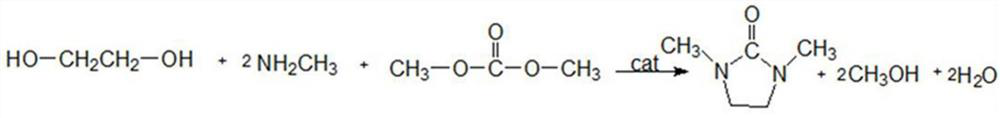

A technology of imidazolinone and production method, applied in 1 field, can solve problems such as no target product, achieve high selectivity, high activity, and prevent sintering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

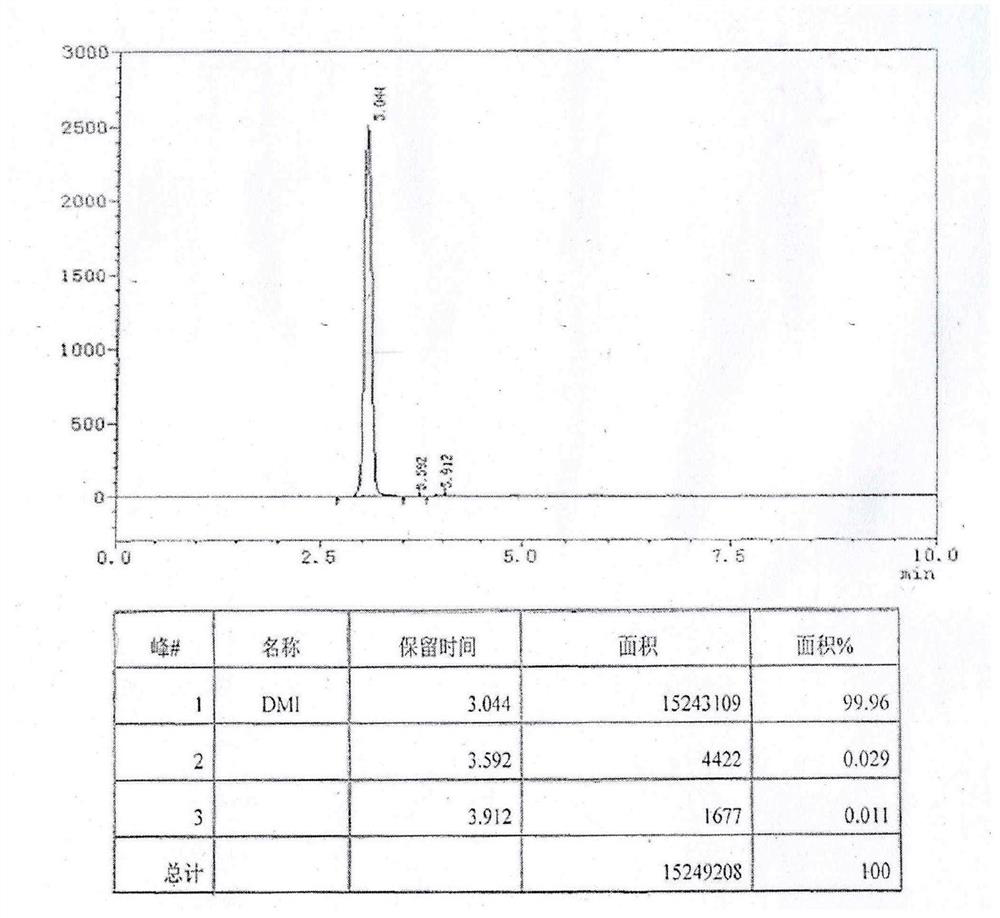

Image

Examples

Embodiment 1

[0051] The continuous production method of 1,3-dimethyl-2-imidazolidinone of the present invention, the detailed steps of described continuous production method are as follows:

[0052] 1) Preparation of heterogeneous catalyst:

[0053] a. Dissolve nickel nitrate, ferric nitrate, zinc acetate and molybdenum nitrate in deionized water to prepare a solution A with a concentration of 0.8mol / L, stir well; heat up the prepared solution A to 65°C, and then Add a silica sol emulsion with a mass percentage of silica of 20%, and drop it at a temperature of 85°C within 30 minutes; then add a precipitant Na 2 CO 3 Stir to control the end point pH value to 9, move the obtained slurry to a microwave hydrothermal parallel synthesizer to react for 8 hours, filter, wash and bake the obtained reactants in sequence, and calcinate at 650°C for 4 hours after baking. Post-grinding to obtain precursor particles;

[0054] The molar ratio between the contents of Ni, Fe, Zn and Mo in the nickel nit...

Embodiment 2

[0064] The continuous production method of 1,3-dimethyl-2-imidazolidinone of the present invention, the detailed steps of described continuous production method are as follows:

[0065] 1) Preparation of heterogeneous catalyst:

[0066] a. Dissolve nickel nitrate, ferric nitrate, zinc acetate, cobalt nitrate and molybdenum nitrate in deionized water to prepare a solution A with a concentration of 1.0 mol / L, stir well; heat up the prepared solution A to 70 ℃, then add a silica sol emulsion with a mass percentage of silicon dioxide of 15%, and drop it at a temperature of 80 ℃ within 25 minutes; then add a precipitant NaHCO 3 Stirring is carried out to control the pH value at the end point to be 8, and the obtained slurry is transferred to a microwave hydrothermal parallel synthesizer to react for 7 hours, and the obtained reactants are sequentially filtered, washed and baked, and calcined at 750°C for 3 hours after baking. Post-grinding to obtain precursor particles;

[0067] ...

Embodiment 3

[0077] The continuous production method of 1,3-dimethyl-2-imidazolidinone of the present invention, the detailed steps of described continuous production method are as follows:

[0078] 1) Preparation of heterogeneous catalyst:

[0079] a. Dissolve nickel nitrate, ferric nitrate, zinc acetate and molybdenum nitrate in deionized water to prepare a solution A with a concentration of 0.5mol / L, and stir well; heat up the prepared solution A to 60°C, and then Add a silica sol emulsion with a mass percentage of silica of 25%, and drop it at a temperature of 90°C within 20 minutes; then add a precipitant K 2 CO 3 Stir to control the end point pH value to 8, move the obtained slurry to a microwave hydrothermal parallel synthesizer to react for 8 hours, filter, wash and bake the obtained reactants in sequence, and calcinate at 550°C for 4 hours after baking. Post-grinding to obtain precursor particles;

[0080] The molar ratio between the contents of Ni, Fe, Zn and Mo in the nickel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com