Reducing agent monomer for preparing styrene-acrylic emulsion through oxidation reduction at normal temperature and synthesis method thereof

A technology of styrene-acrylic emulsion and synthesis method, which is applied in chemical instruments and methods, preparation of organic compounds, preparation of amino hydroxyl compounds, etc., can solve problems such as poor water resistance of paint films, and achieve low price, high molecular weight, and synthetic raw materials cheap and easy results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Reductant Monomer Synthesis

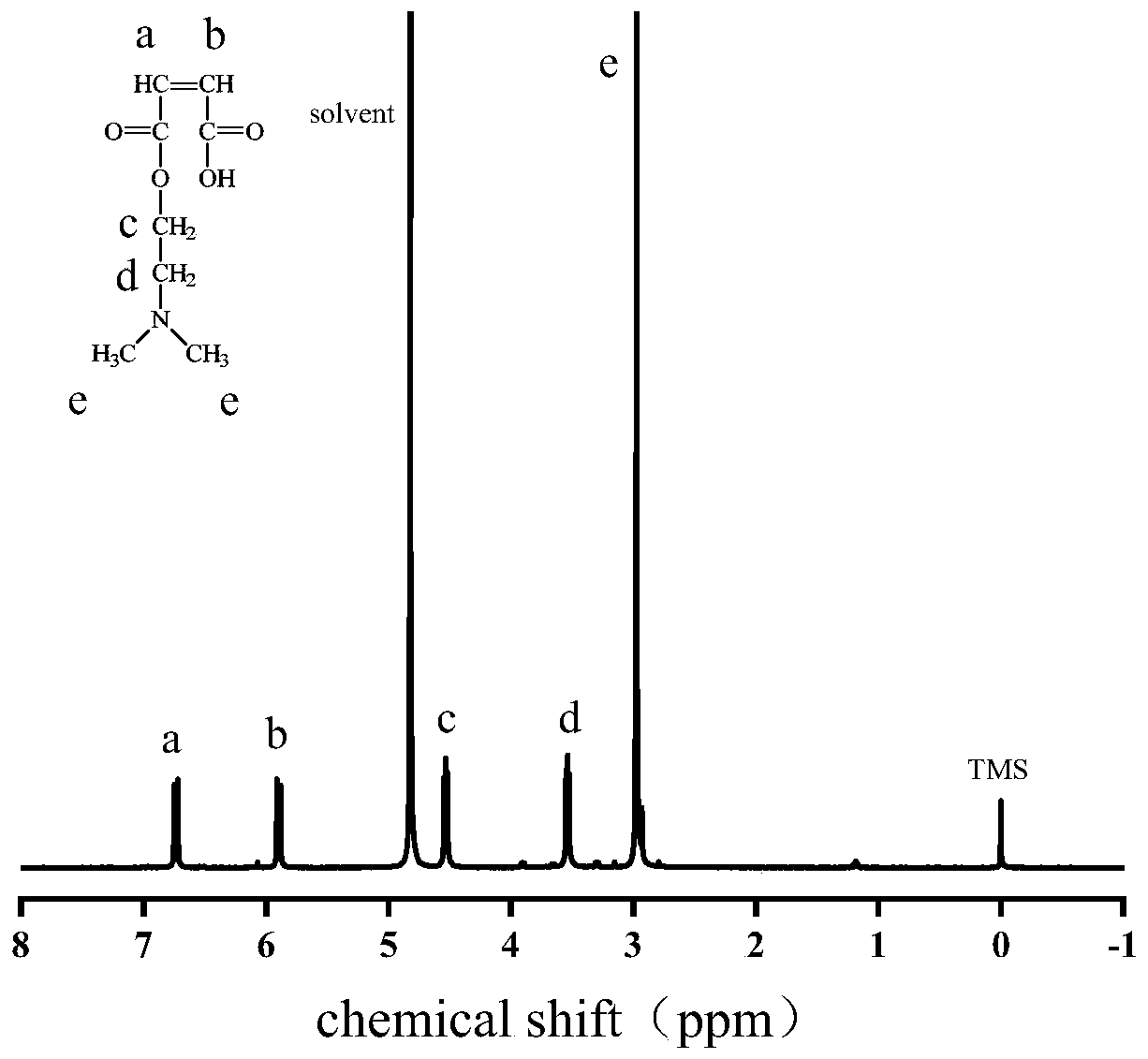

[0034] Add maleic anhydride (4.9 g, 0.05 mol) into a three-necked flask equipped with a thermometer. Add 30ml of chloroform, stir to dissolve at room temperature, after the maleic anhydride is completely dissolved, then dissolve dimethylethanolamine (4.5g, 0.05mol) into 10ml of chloroform, and add it to the reaction flask all at once. After reacting at room temperature for 5 hours, a white suspension was obtained, and the reaction was terminated. Add 40ml of ether, shake well, centrifuge and take the next layer of white solid. It was washed with 40 ml of diethyl ether, filtered twice with suction, and dried in vacuo to constant weight to obtain a white powder. The total yield is 94.5%. For product NMR, please refer to the accompanying drawings figure 1 .

Embodiment 2

[0036] Reductant Monomer Synthesis

[0037] Add maleic anhydride (4.9 g, 0.05 mol) into a three-necked flask equipped with a thermometer. Add 30ml of chloroform, stir and dissolve at room temperature, after the maleic anhydride is completely dissolved, then dissolve dimethylethanolamine (2.3g, 0.025mol) into 8ml of chloroform, and add it to the reaction flask all at once. After reacting at room temperature for 4 hours, a white suspension was obtained, and the reaction was terminated. Add 40ml of ether, shake well, centrifuge and take the next layer of white solid. It was washed with 40 ml of diethyl ether, filtered twice with suction, and dried in vacuo to constant weight to obtain a white powder. The total yield is 65.7%.

Embodiment 3

[0039] Reductant Monomer Synthesis

[0040] Add maleic anhydride (4.9 g, 0.05 mol) into a three-necked flask equipped with a thermometer. Add 30ml of chloroform, stir to dissolve at room temperature, after the maleic anhydride is completely dissolved, then dissolve dimethylethanolamine (9.0g, 0.10mol) into 20ml of chloroform, and add it to the reaction flask all at once. After reacting at room temperature for 8 hours, a white suspension was obtained, and the reaction was terminated. Add 40ml of ether, shake well, centrifuge and take the next layer of white solid. It was washed with 40 ml of diethyl ether, filtered twice with suction, and dried in vacuo to constant weight to obtain a white powder. The total yield is 57.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com