Hydrogen-containing metal combustion agent and preparation method thereof

A kind of incendiary and metal technology, used in offensive equipment, single substance used as explosives, explosives, etc., can solve the problems of energy release and dispersion, inability to concentrate heat release, aluminum phase is difficult to burn, etc., to increase the combustion reaction interface and activity, The effect of improving combustion performance and reducing ignition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] According to the molar ratio of 2:[1 / (1-x)] (x=18%, which is the loss rate of magnesium in the smelting process), weigh aluminum flakes and magnesium strips with a purity of not less than 99.5%; use vacuum induction The smelting method is to smelt aluminum flakes and magnesium strips into alloys; mechanically crush the alloys obtained by smelting into powders with a particle size of less than 300 mesh; carry out two cycles of hydrogen absorption and desorption at 400°C (hydrogen absorption under 8 MPa hydrogen pressure for 24 hours, vacuum After dehydrogenation for 1h), absorb hydrogen for 24h under 8MPa hydrogen pressure to obtain the hydrogen-containing metal combustion agent, i.e. Al 2 Mg alloy hydride.

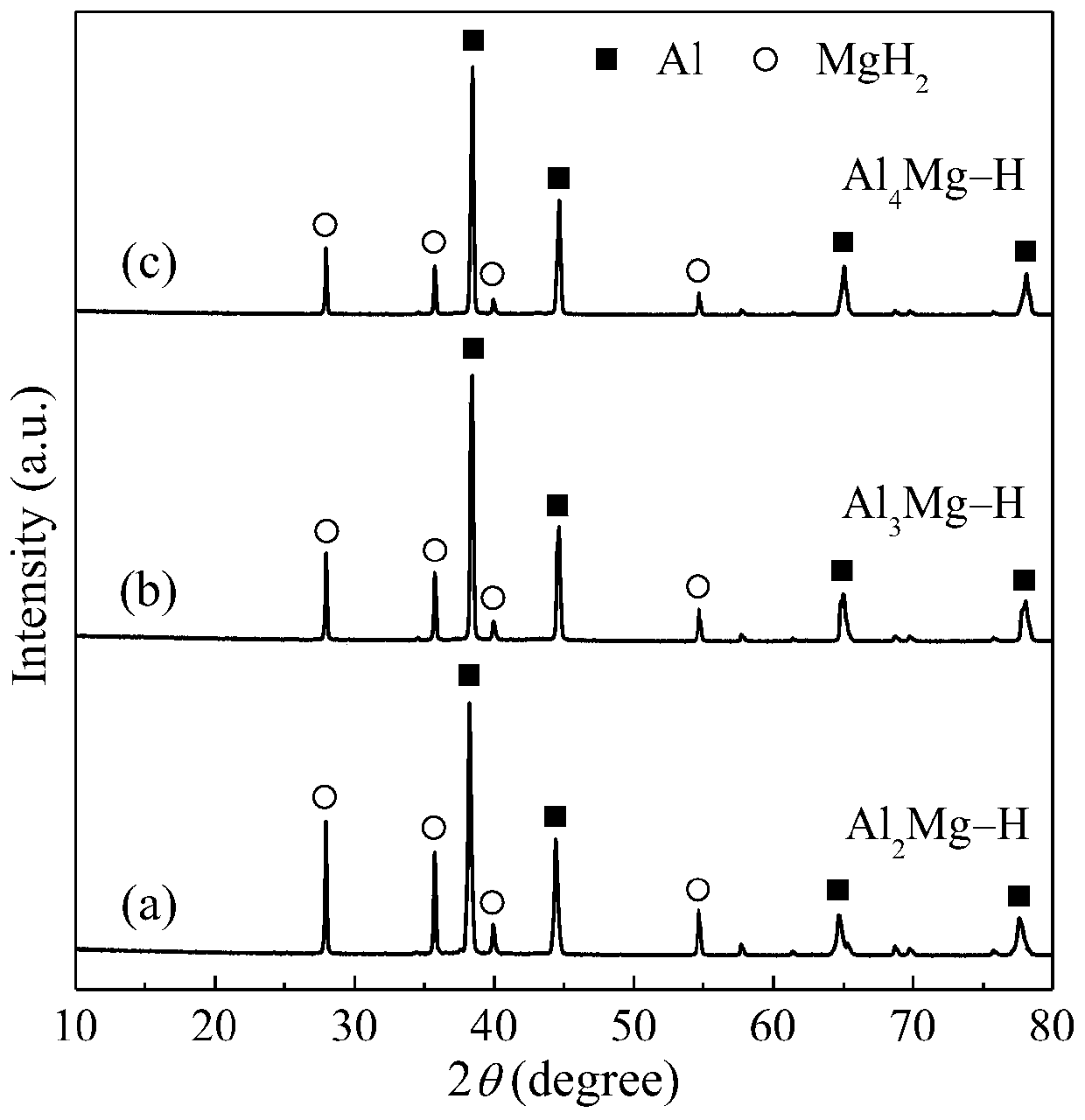

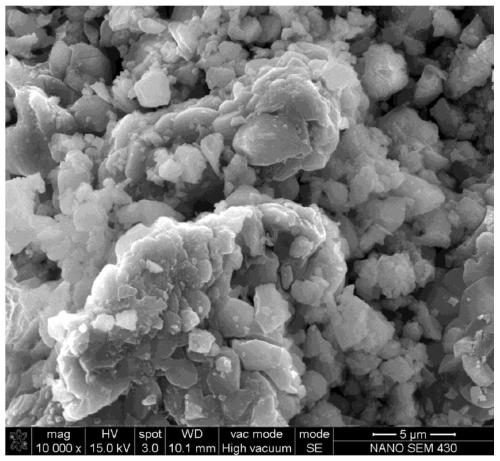

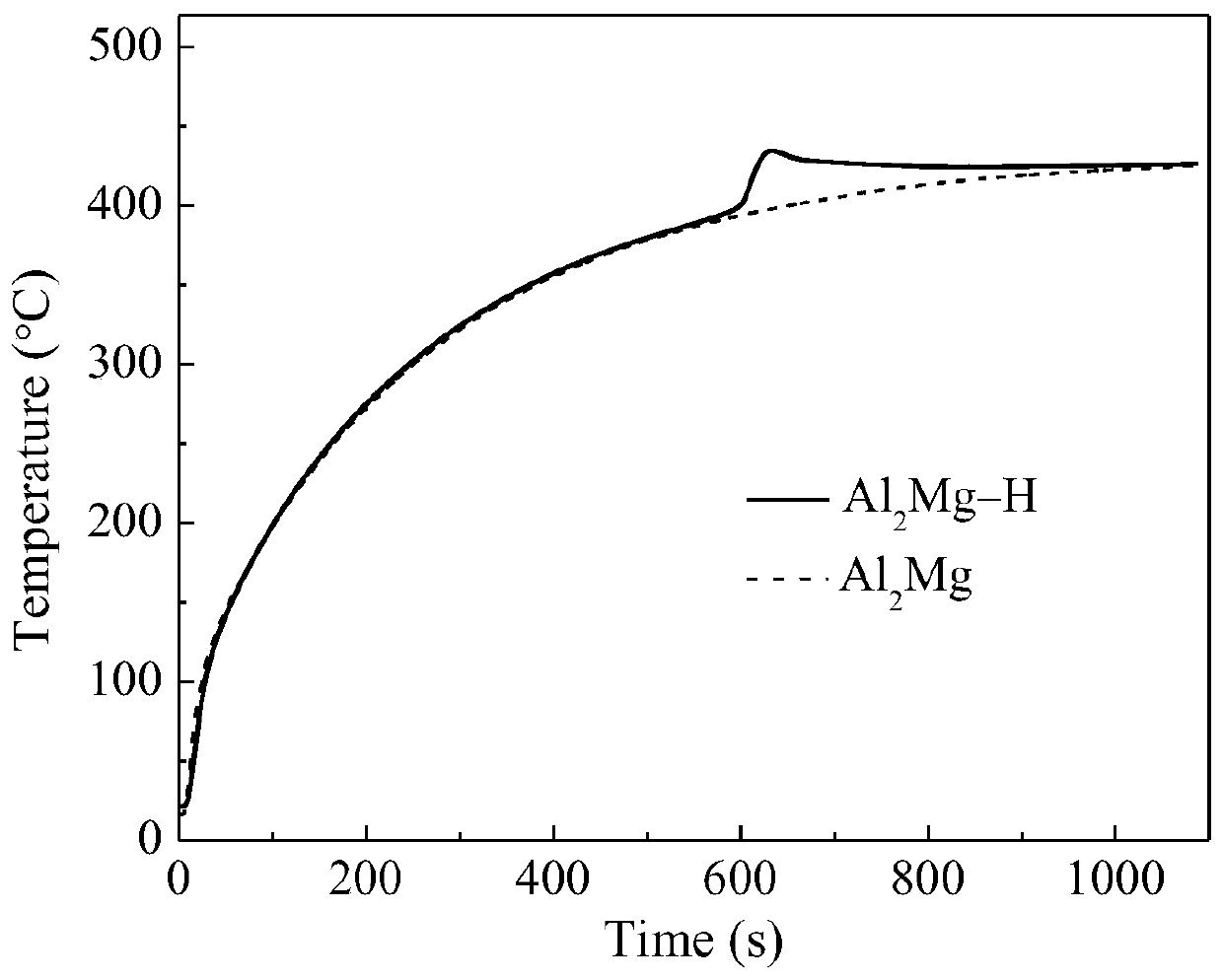

[0028] Depend on figure 1 a and 2 show that the resulting hydrogen-containing metal combustion agent consists of Al and MgH 2 Composed of two phases, its particles are fine, loose and porous. Depend on image 3 Visible, Al 2 Mg alloy hydrides can be ignited and...

Embodiment 2

[0030] According to the molar ratio of 3:[1 / (1-x)] (x=18%, which is the loss rate of magnesium in the smelting process), weigh aluminum sheets and magnesium strips with a purity of not less than 99.5%; use vacuum induction The smelting method is to smelt aluminum flakes and magnesium strips into alloys; mechanically pulverize the smelted alloys into powders with a particle size of less than 300 mesh; carry out two hydrogen absorption and desorption cycles at 350 ° C (8 MPa hydrogen pressure for 24 hours, vacuum After dehydrogenation for 1h), absorb hydrogen for 24h under 8MPa hydrogen pressure to obtain the hydrogen-containing metal combustion agent, i.e. Al 3 Mg alloy hydride. Depend on figure 1 b It can be seen that the resulting hydrogen-containing metal combustion agent is composed of Al and MgH 2 Two-phase composition.

Embodiment 3

[0032] According to the molar ratio of 4:[1 / (1-x)] (x=18%, which is the loss rate of magnesium in the smelting process), weigh aluminum sheets and magnesium strips with a purity of not less than 99.5%; use vacuum induction The smelting method is to smelt aluminum flakes and magnesium strips into alloys; mechanically crush the alloys obtained by smelting into powders with a particle size of less than 300 mesh; carry out two cycles of hydrogen absorption and desorption at 400°C (hydrogen absorption under 8 MPa hydrogen pressure for 24 hours, vacuum After dehydrogenation for 1h), absorb hydrogen for 24h under 8MPa hydrogen pressure to obtain the hydrogen-containing metal combustion agent, i.e. Al 4 Mg alloy hydride. Depend on figure 1 c shows that the resulting hydrogen-containing metal combustion agent consists of Al and MgH 2 Two-phase composition. Depend on Figure 5 Visible, Al 4 The ignition temperature of Mg alloy hydride is about 375°C, and the oxidation combustion re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com