Method for culturing hydrogen autotrophic denitrification granular sludge

A technology of autotrophic denitrification and nitrification granules, which is applied in the field of cultivating hydrogen autotrophic denitrification granular sludge, to achieve the effects of increasing sludge age, increasing operating load, and good settling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

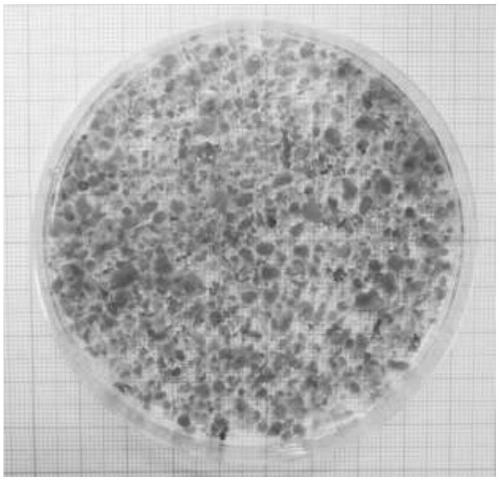

Image

Examples

Embodiment 1

[0050] Embodiment 1, cultivating hydrogen autotrophic denitrification granular sludge

[0051] 1) Domestication and cultivation of hydroautotrophic denitrification flocculent sludge

[0052] Take the activated sludge of ordinary municipal sewage plant as inoculation sludge, the concentration is about 2.3gVSS / L, after inoculation, use H 2 Semi-continuous culture with self-made culture medium for 60 days. The composition of the culture solution is (contains the following substances per liter): 1.62gKNO 3 ,0.5gNaHCO 3 ,0.55gNaH 2 PO 4 2H 2 O, 2.11g K 2 HPO 4 ·3H 2 O and trace elements 7.3mgCaCl 2 2H 2 O,5.0mgFeSO 4 ·7H 2 O,2.5mgMnCl 2 4H 2 O,0.5mgCoCl 2 ·6H 2 O, 0.5mg (NH 4 ) 6 Mo 7 o 24 4H 2 O,0.22mgZnSO 4 ·7H 2 O and 0.2 mg CuSO 4 ·5H 2 O. The method of domestication and culture is sequential batch, and the sequence batch cycle is 12h. The pH of the culture system is 7.0±0.5, and the temperature is 30±1.0°C.

[0053] 2) The hydroautotrophic denitrifi...

Embodiment 2

[0057] Example 2, using hydrogen autotrophic denitrification granular sludge reactor to treat simulated groundwater

[0058] Utilize the hydroautotrophic denitrification granular sludge cultivated in Example 1 to treat groundwater, maintain the reaction temperature at 30±0.5°C, add an appropriate amount of KNO 3 The simulated groundwater was used as the reactor feed water, and the denitrification effect, stability and effluent NO of the reactor were investigated. 2 - -N level.

[0059] The sludge used in this test is the hydroautotrophic denitrification granular sludge cultivated in Example 1, and the inoculation sludge concentration in the reactor is 2.44g VSS / L.

[0060] The granular sludge reactor operates continuously for 12 days in accordance with the SBR method, and each SBR cycle is 35 minutes, including water inflow for 3 minutes, reaction for 22 minutes, precipitation for 8 minutes, and drainage for 2 minutes. The test water is to add a certain amount of KNO 3 tap...

Embodiment 3

[0064] Example 3, using hydrogen autotrophic denitrification granular sludge reactor to treat simulated groundwater under low temperature conditions

[0065] Utilize the hydroautotrophic denitrification granular sludge cultivated in Example 1 to treat groundwater, maintain the reaction temperature at 15±0.3°C, add an appropriate amount of KNO 3 The simulated groundwater was used as the reactor feed water, and the denitrification effect, stability and effluent NO of the reactor were investigated. 2 - -N level.

[0066] The sludge and reactor used in this test are the hydrogen autotrophic denitrification granular sludge and sludge after the end of Example 2.

[0067] The granular sludge reactor operates continuously for 11 days in accordance with the SBR method, in which the cycle is 85 min for 7 days and the cycle is 75 min for 4 days. When the cycle is 85 minutes, water is fed for 3 minutes, reaction is 72 minutes, precipitation is 8 minutes, and water is drained for 2 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com