Centrifugal compression type pressure swing adsorption oxygen generator

A pressure swing adsorption oxygen production and centrifugal compressor technology, which is applied in the field of oxygen generators, can solve the problems of large capacity and high noise, and achieve the effects of volume reduction, pressure loss saving, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

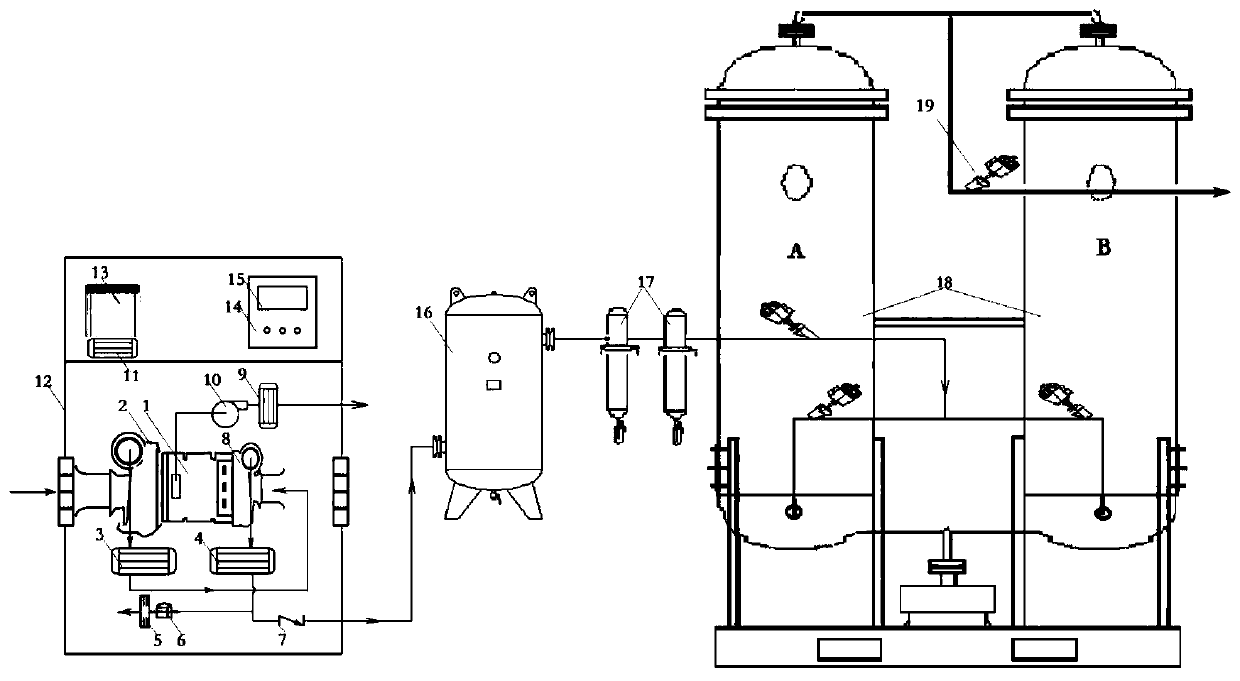

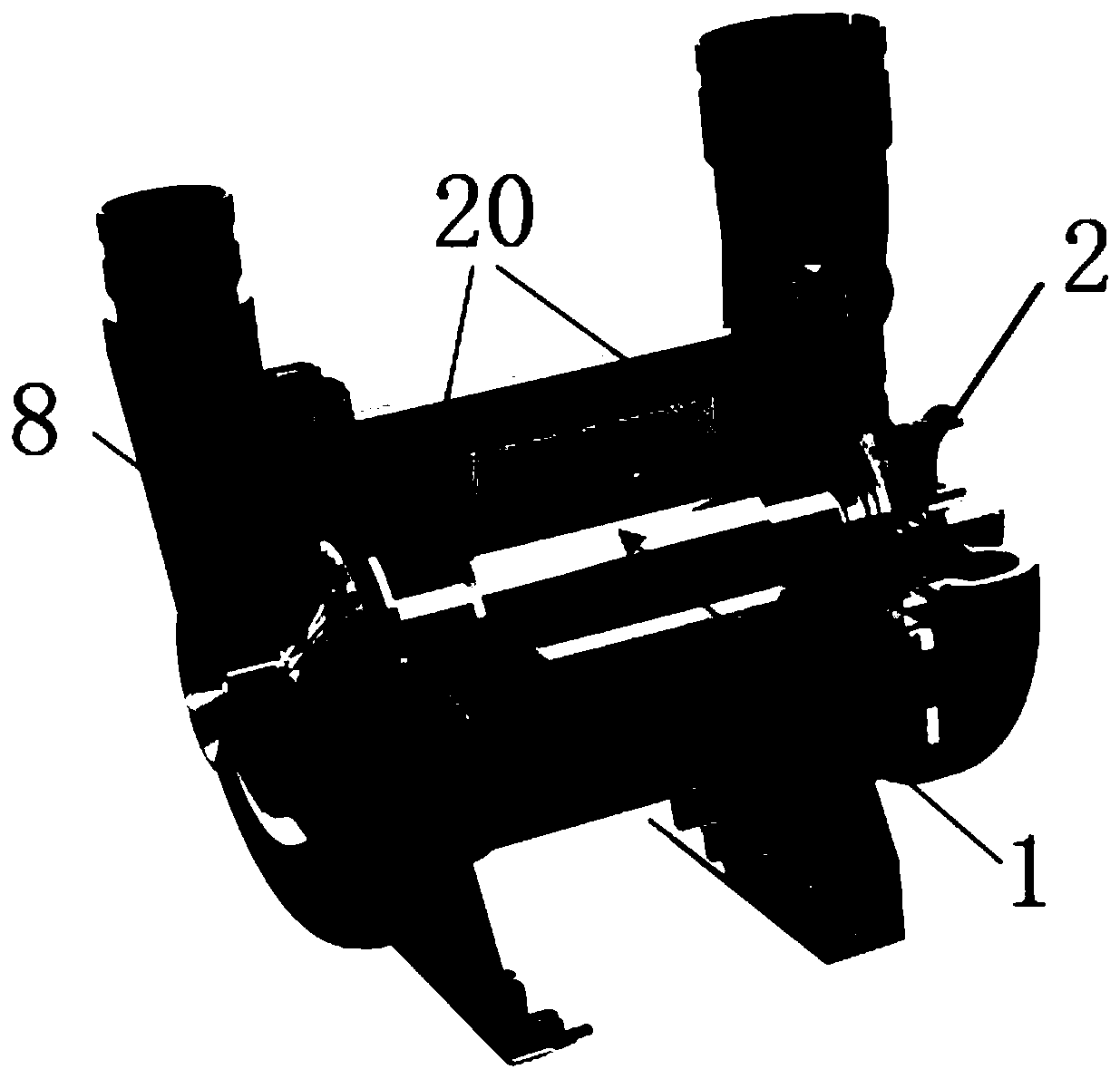

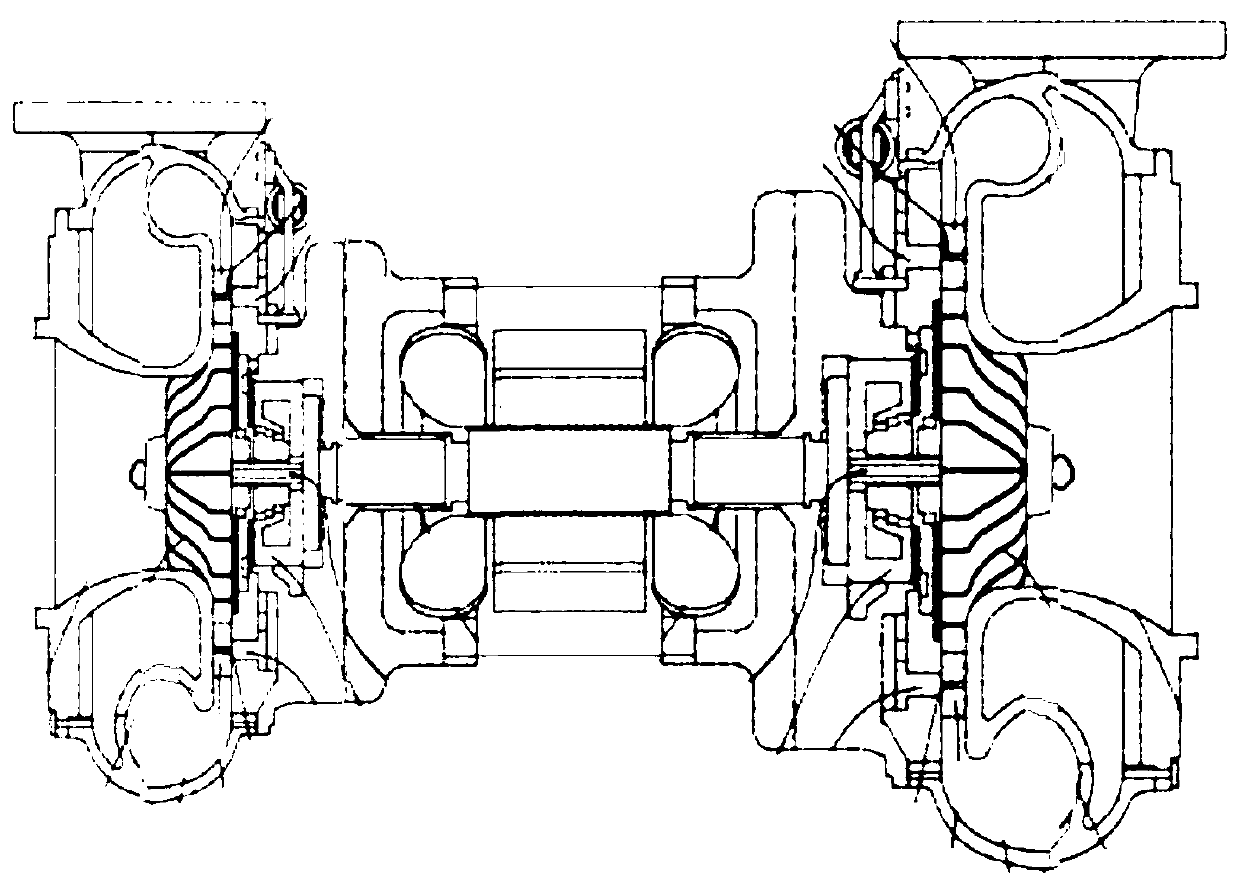

[0026] see Figure 1-4 Description of this embodiment, a centrifugal compression pressure swing adsorption oxygen generator, which includes a centrifugal compressor, an intercooler 3, an aftercooler 4, a buffer tank 16, a filter 17 and a pressure swing adsorption tower 18, the centrifugal compressor Including the motor 1, the first impeller 2, the second impeller 8 and the suspension bearing 20, the output shafts at both ends of the motor 1 are directly coupled with the first impeller 2 and the second impeller 8 through the support of the suspension bearing 20, and the two sides of the intercooler 3 The ports are respectively connected to the outlet end of the first impeller 2 and the inlet end of the second impeller 8, the outlet end of the second impeller 8 is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com