Degradable film and preparation method thereof

A technology for degrading films and films, applied in chemical instruments and methods, sustainable manufacturing/processing, climate sustainability, etc. The effect of low temperature heat sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

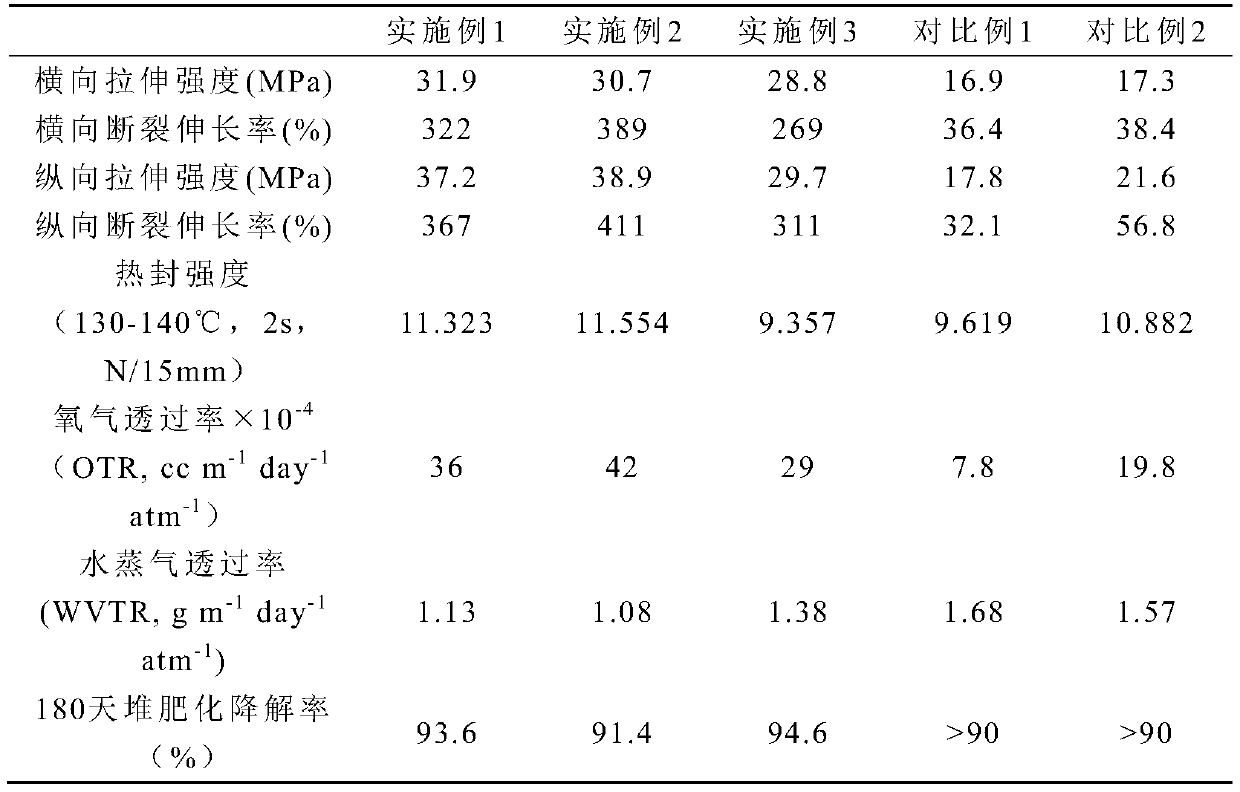

Examples

Embodiment 1

[0042] The degradable film of this embodiment includes an inner layer and an outer layer, wherein the inner layer comprises the following components in parts by weight: 80 parts of polylactic acid-glycolic acid copolymer, 65 parts of polycaprolactone, methacrylic acid shrinkage 4 parts of glyceride grafted polycaprolactone, 10 parts of polyhydroxyalkanoate, 2 parts of polylactic acid-caprolactone copolymer, 0.2 part of flake graphite;

[0043] The outer layer includes the following components in parts by weight: 100 parts of polylactic acid-glycolic acid copolymer, 60 parts of polycaprolactone, 20 parts of diacetyl epoxy vegetable glyceryl oleate, glycidyl methacrylate graft 10 parts of polylactic acid-glycolic acid copolymer, 1.8 parts of nano calcium carbonate, 1.2 parts of sodium alginate, 4 parts of slip agent, 12 parts of antistatic agent, 0.4 part of ultraviolet absorber;

[0044]The degradable film of this embodiment also includes a core layer, wherein the core layer in...

Embodiment 2

[0057] The degradable film of this embodiment includes an inner layer and an outer layer, wherein the inner layer comprises the following components in parts by weight: 60 parts of polylactic acid-glycolic acid copolymer, 20 parts of polycaprolactone, methacrylic acid shrinkage 15 parts of glyceride grafted polycaprolactone, 2 parts of poly-β-hydroxybutyric acid, 2 parts of polymethylethylene carbonate, 0.5 part of talcum powder, 1 part of diatomaceous earth;

[0058] Wherein the outer layer comprises the following components in parts by weight: 70 parts of polylactic acid-glycolic acid copolymer, 50 parts of polycaprolactone, 12 parts of diacetyl epoxy vegetable glyceryl oleate, glycidyl methacrylate 18 parts of grafted polylactic acid-glycolic acid copolymer, 0.3 parts of chitosan, 1.5 parts of montmorillonite, 6 parts of functional additives;

[0059] The degradable of this embodiment also includes a core layer, the core layer includes the following components in parts by w...

Embodiment 3

[0072] The degradable film of this embodiment includes an inner layer and an outer layer, wherein the inner layer comprises the following components in parts by weight: 70 parts of polylactic acid-glycolic acid copolymer, 45 parts of polycaprolactone, glycidyl methacrylate 2.5 parts of ester-grafted polycaprolactone, 15 parts of polybutylene adipate terephthalate, 4 parts of polylactic acid-caprolactone copolymer, and 4 parts of open-ended masterbatch;

[0073] Wherein the outer layer comprises the following components in parts by weight: 60 parts of polylactic acid-glycolic acid copolymer, 20 parts of polycaprolactone, 8 parts of diacetyl epoxy vegetable glyceryl oleate, glycidyl methacrylate 2 parts of dendritic polylactic acid-glycolic acid copolymer, 7.5 parts of mica powder, 3 parts of cellulose nanocrystals, and 4 parts of functional additives.

[0074] This embodiment provides a method for preparing the above-mentioned degradable poly film. The preparation steps are as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com