Low-temperature plasma mask sterilization and repair electret machine and method

A low-temperature plasma and plasma technology, which is applied in the directions of plasma, dryer, drying gas arrangement, etc., can solve the problems of inability to use non-woven materials, difficult to ensure uniform particle flow, complex shape of masks, etc. Electro-adsorption capacity, the effect of promoting high-energy electron emission and improving electron penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

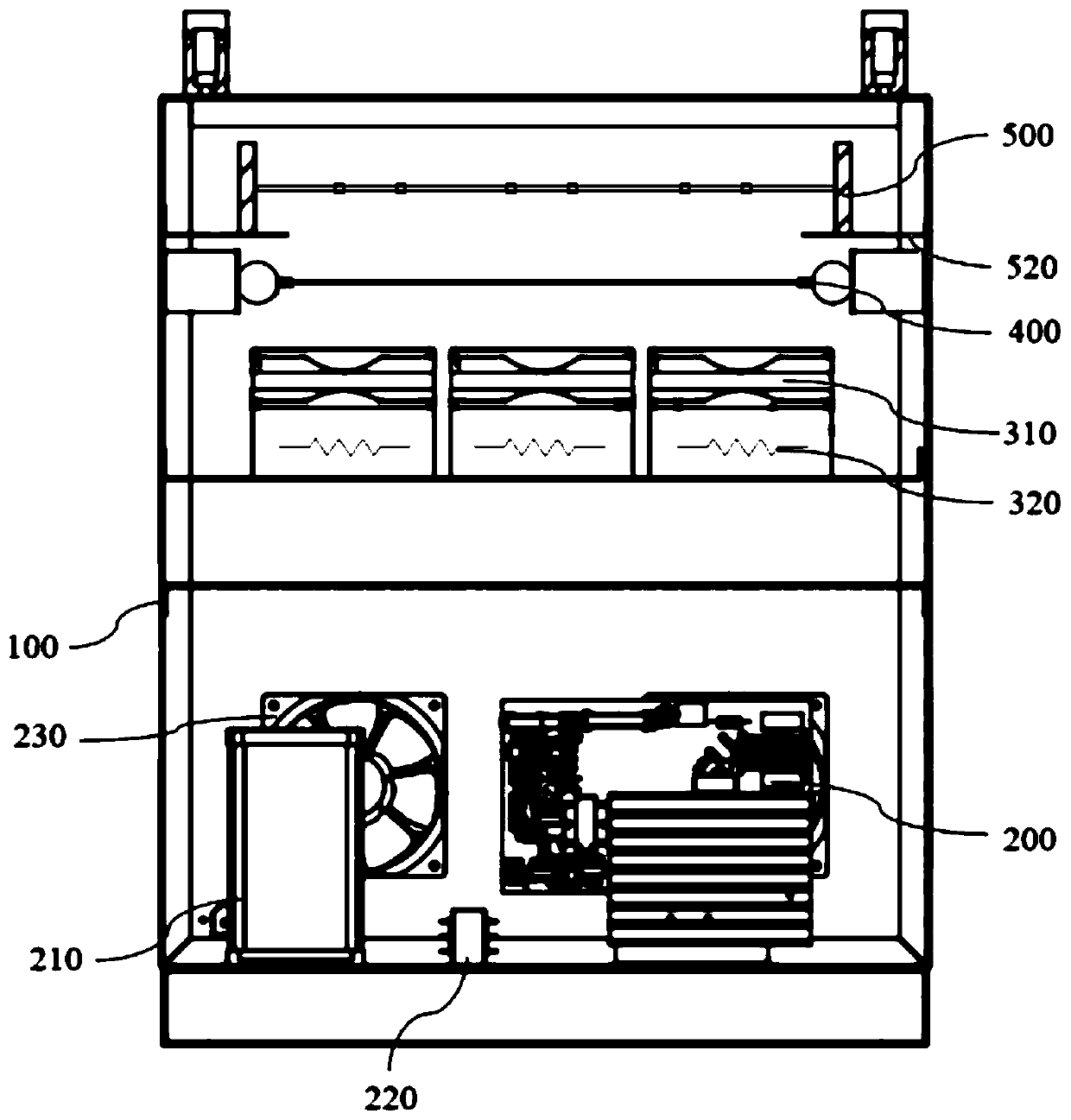

[0042] Combine figure 1 , figure 2 with Figure 5 In this embodiment, a low-temperature plasma mask sterilization and repair electret machine includes a housing 100 in which a power supply 200, a heating device, a blowing device, a plasma electret device 400, and a plasma electret device 400 are arranged in order from bottom to top. Mask fixing device 500, the power supply adopts DC power supply or AC power supply, combined Image 6 , Figure 7 , The AC power supply is preferably an AC pulse power supply. According to different characteristics of materials and different electret requirements, only need to adjust the power supply to reverse the output, which can realize the switching of positive / negative pulse high voltage and meet the material's requirements for electret polarity. Through power adjustment, the pulse width can be adjusted to freely control the effective electret time in a single cycle. Image 6 with Figure 7 The dotted line in the middle is a schematic diagram o...

Embodiment 2

[0049] Combine figure 1 with 2 The difference between this embodiment and embodiment 1 is:

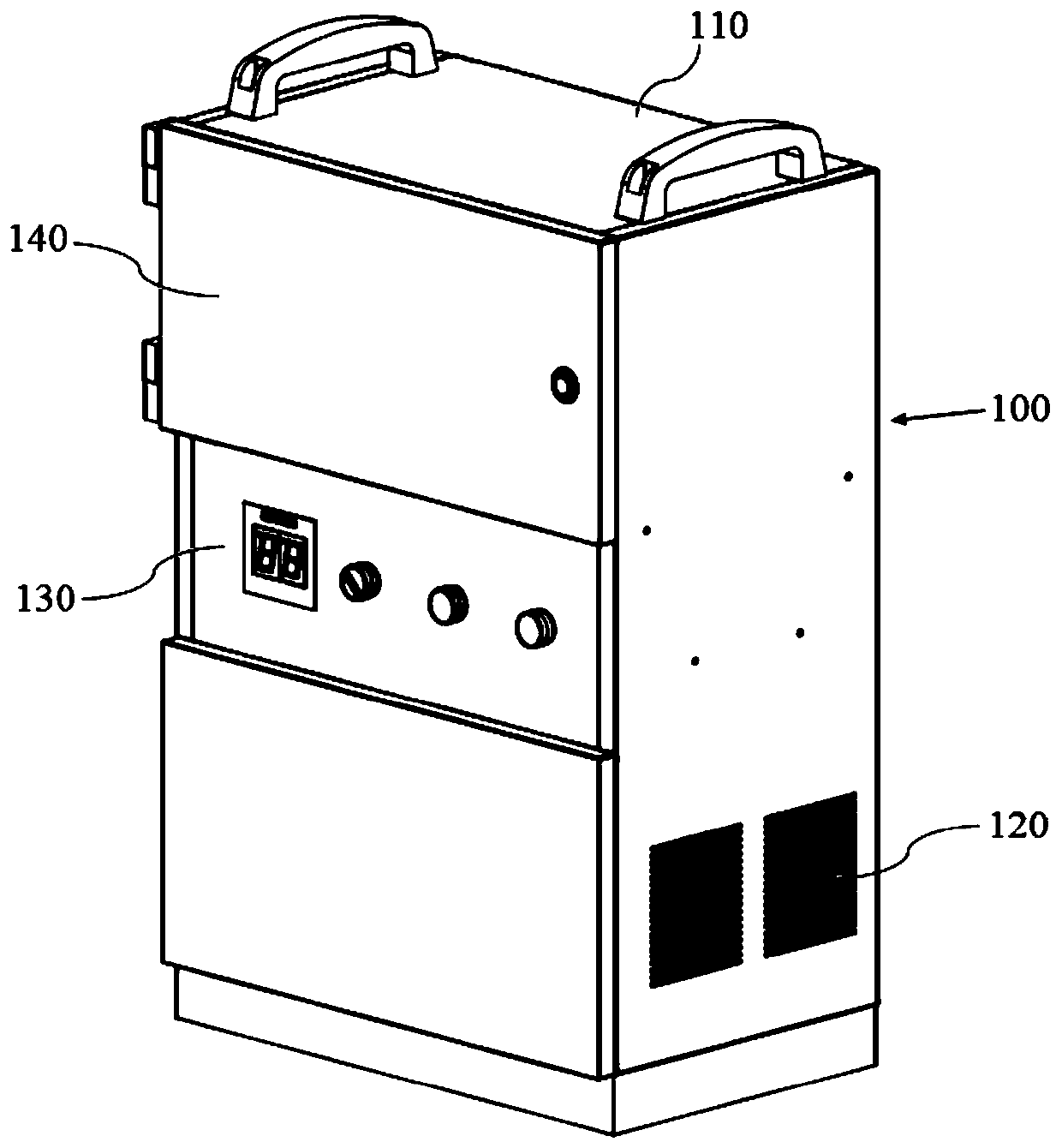

[0050] The side wall of the casing 100 is provided with a heat dissipation port to dissipate heat from the power supply, preferably a heat dissipation grill 120, and a transformer radiator 230 is provided on the rear wall of the casing, which may be a fan structure to dissipate heat from the transformer. The top wall 110 of the housing 100 is provided with two grippers, preferably two, to facilitate the transportation of the low-temperature plasma mask sterilization repair machine.

[0051] The housing 100 is provided with a control panel 130 for timing and controlling the switching and power of the heating resistor 320, the fan 310, and the power supply 200, and the three parameters of processing time, processing temperature, and discharge power can be flexibly adjusted.

Embodiment 3

[0053] A low-temperature plasma mask sterilization and repair electret method of this embodiment,

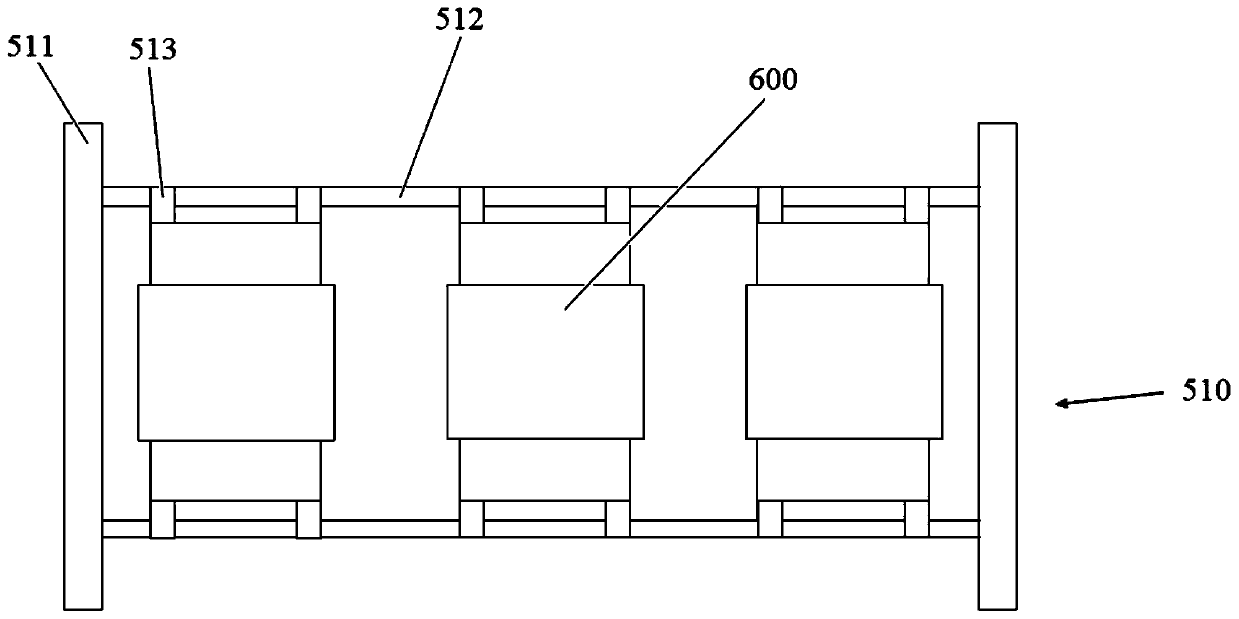

[0054] Install the mask 600 to be processed on the mask holder 510, keep the mask in the mask holder 510 vertically placed above the plasma electrode wire array 410, and place it close to the plasma electrode wire array 410. The mask holder 510 can be used for one Preparation, or multiple preparations for one use, processing one batch at the same time prepares the rest to be processed, increasing the processing output;

[0055] For electret treatment, the plasma electrode wire array 411 is connected to the high voltage end of the power supply 200, and the casing 100 is connected to the low voltage end of the power supply 200. The power supply 200 uses a negative bias AC power supply. The plasma electrode wire array 411 is formed between the casing 100 Electric field, the mask 600 to be processed held by the mask clamp 510 is in an electric field, and electret processing is completed....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com