High cerium rare earth ferrosilicon alloy and production method thereof

A technology of rare earth ferrosilicon alloy and production method, which is applied in the field of metal smelting, can solve the problems of severe alloy pulverization, low rare earth yield, and high production cost of rare earth ferrosilicon alloy, and achieve weakened equipment corrosion, good economic benefits, and improved utilization of rare earth resources rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

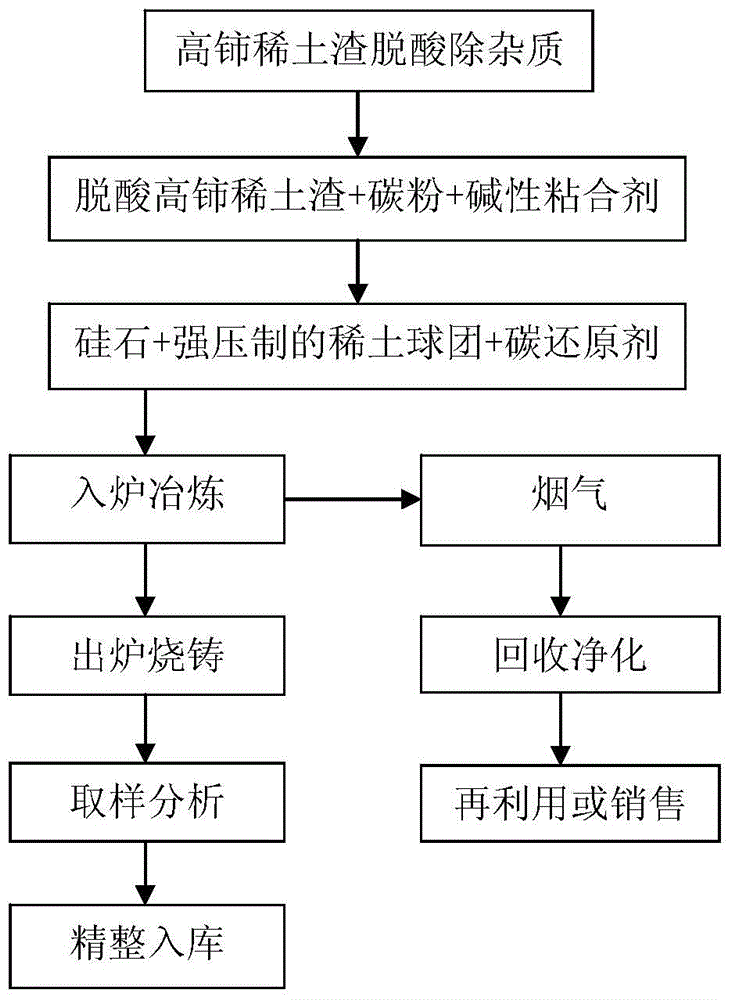

Method used

Image

Examples

Embodiment 1

[0049] a. Add water glass to 100kg of ceric rare earth slag to deacidify the ceric rare earth slag to a pH value of 6.8;

[0050] b. Add 25kg of carbon powder and 35kg of alkaline binder to the deacidified ceric rare earth slag, and press it into rare earth pellets;

[0051] c. Put 228kg of silica, 171kg of carbon reducing agent and the above-mentioned rare earth pellets together into the furnace for smelting for 2.5 hours, take them out of the furnace and cast them, and obtain high-cerium rare earth ferrosilicon alloy.

[0052] The composition of the high cerium rare earth ferrosilicon alloy obtained in this embodiment is calculated by mass percentage: RE is 29%, Si is 49.5%, Ca is 0.09%, Al is 0.45%, wherein Ce / RE is 85%, and the rest For Fe.

Embodiment 2

[0054] a. Add water glass to 200kg of ceric rare earth slag to deacidify the ceric rare earth slag to a pH value of 7.5;

[0055] b. Add 56kg of carbon powder and 76kg of alkaline binder to the deacidified ceric rare earth slag, and press it into rare earth pellets;

[0056] c. Put 500kg of silica, 397kg of carbon reducing agent and the above-mentioned rare earth pellets together into the furnace for smelting for 3 hours, take them out of the furnace and cast them, and obtain high-cerium rare earth ferrosilicon alloy.

[0057] The composition of the high cerium rare earth ferrosilicon alloy obtained in this embodiment is calculated by mass percentage: RE is 30.85%, Si is 50.5%, Ca is 0.1%, Al is 0.49%, wherein Ce / RE is 87%, and the rest For Fe.

Embodiment 3

[0059] a. Add water glass to 50kg of ceric rare earth slag to deacidify the ceric rare earth slag to a pH value of 7.2;

[0060] b. Add 13.25kg of carbon powder and 18.25kg of alkaline binder to the deacidified ceric rare earth slag, and press it into rare earth pellets;

[0061] c. Put 120kg of silica, 92kg of carbon reducing agent and the above-mentioned rare earth pellets together into the furnace for smelting for 3 hours, take them out of the furnace and cast them, and obtain high-cerium rare earth ferrosilicon alloy.

[0062] The composition of the high cerium rare earth ferrosilicon alloy obtained in this embodiment is calculated by mass percentage: RE is 30.98%, Si is 50.95%, Ca is 0.09%, Al is 0.48%, wherein Ce / RE is 87.4%, and the rest For Fe.

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com