A cell stack structure of a flat tubular solid oxide fuel cell

A solid oxide and fuel cell technology, applied in the field of battery stack structure, can solve the problems of cathode side current collection difficulty, cathode current collection difficulty, long current path, etc., and achieve volumetric power density improvement, series-parallel flexibility, and strength improvement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

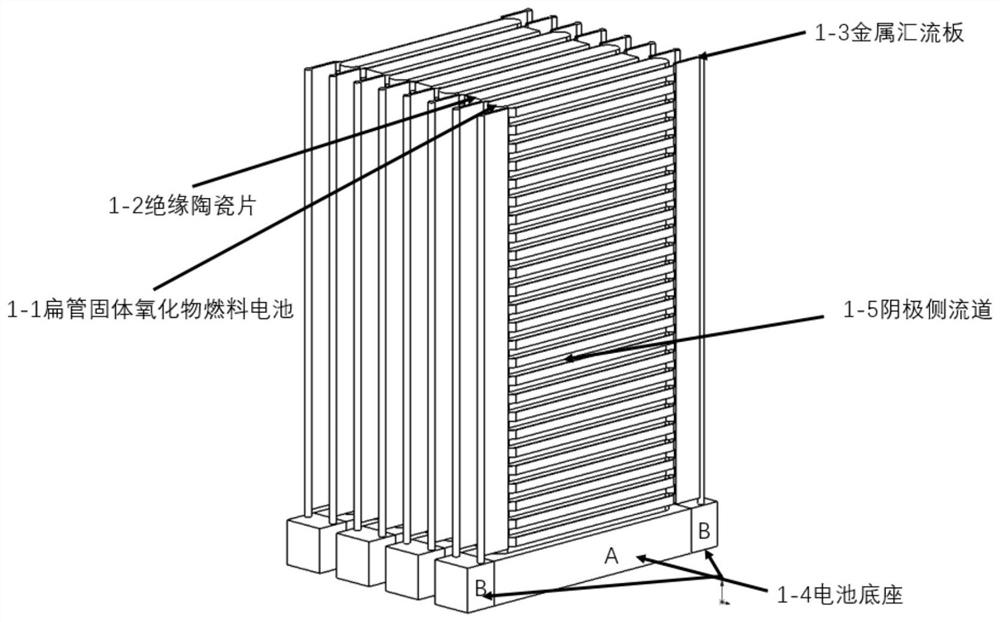

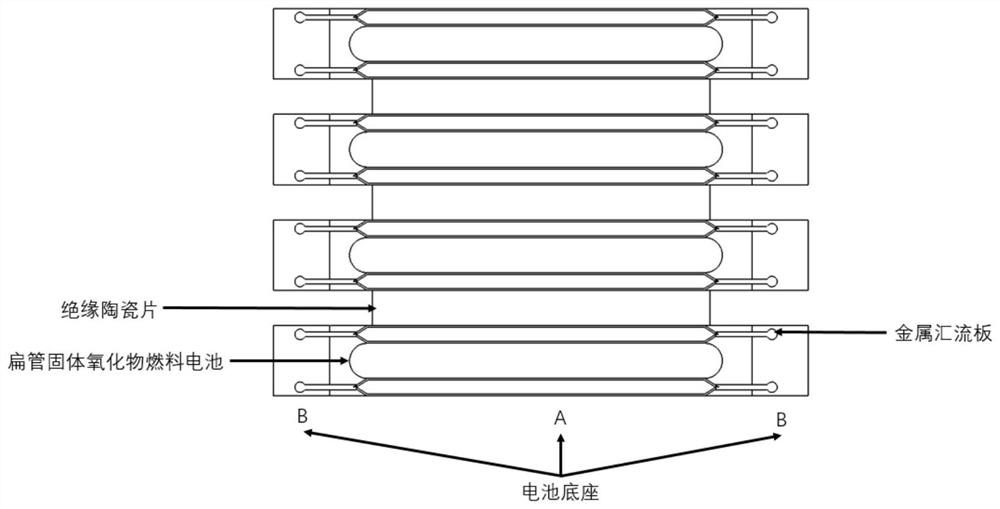

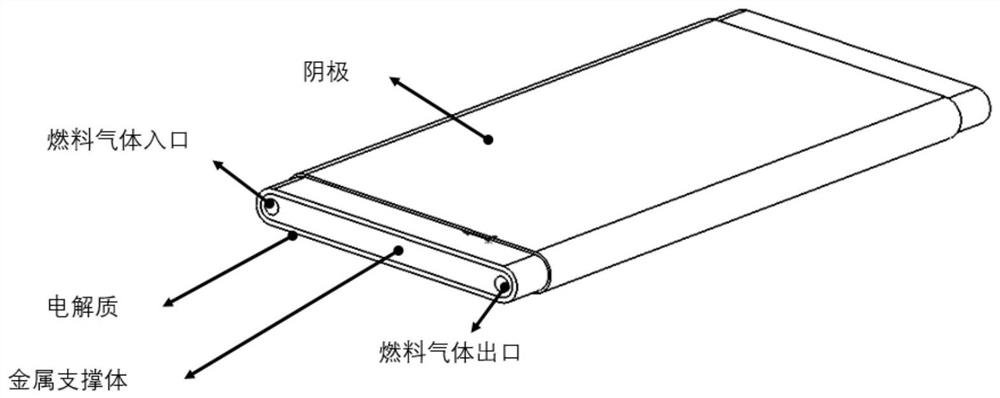

[0074] Stamping the metal manifold into figure 1 and figure 2 The structure shown will be image 3 and Figure 4 The metal-supported flat-tube solid oxide fuel cell with the structure shown is placed in the metal base A, and the battery and the base are fixed and sealed by brazing and welding. The metal manifold is placed on the cathodes on both sides, and the metal manifold base B and The metal bases A are insulated to form a battery unit. Insulating ceramic sheets are placed between the 30 single cells installed in this way, so that the metal bus plate is fixed to the cathode of the battery by elastic force. The anode and cathode of each single cell are respectively drawn out from the metal base A and the metal base B, such as figure 1 and figure 2 As shown, subsequent independent series-parallel connection.

Embodiment 2

[0076] Stamping the metal manifold into Figure 7 The structure shown will be Figure 4 and Figure 5 The ceramic support flat tube solid oxide fuel cell with the structure shown is placed in the metal base A, the battery and the base are fixed and sealed with glass sealant, the metal manifold is placed on the cathodes on both sides, and the metal manifold base B is connected to the metal base A is insulated to form a battery unit. Place insulating ceramic sheets between the 50 single cells installed in this way, so that the metal bus plate is fixed to the cathode of the battery by elastic force. The anode current and cathode current of each single cell are respectively drawn from the metal base A and the metal base B, such as Figure 7 As shown, subsequent independent series-parallel connection.

Embodiment 3

[0078] Will Figure 5 and Figure 6 Prepare a layer of collector slurry on the cathode of the ceramic support flat tube solid oxide fuel cell with the structure shown, connect the metal collector plate to the cathode, and weld the metal collector plate on the base B. Put the battery into the metal base A, fix and seal the battery and the base with glass sealant, and insulate the metal manifold base B from the metal base A to form a battery unit. Put insulating ceramic sheets between the 15 single cells installed in this way, so that the metal bus plate is fixed to the cathode of the battery by elastic force. The anode current and cathode current of each single cell are respectively drawn from the metal base A and the metal base B, and then independently connected in series and parallel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com