Liquid cooling superposition cell assembly and hydrogen fuel cell stack

A fuel cell stack and battery assembly technology, which is applied to fuel cells, electrical components, circuits, etc., can solve the problems of overheating of single cells, inconvenient installation of stacks, uneven heat dissipation of single cells, etc., and achieves high power generation efficiency and improved Volume power density, easy assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

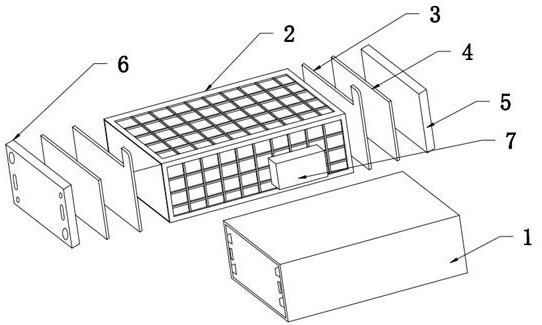

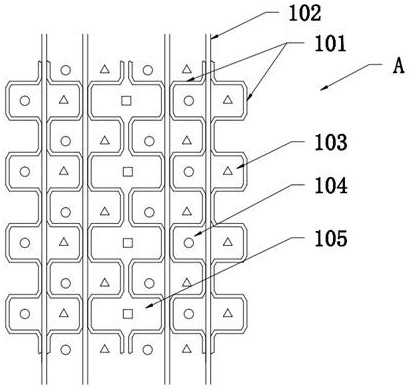

[0033] see Figure 1-4 , the present invention provides a technical solution: a liquid-cooled stacked battery assembly 1, comprising:

[0034] The single cells stacked in series and the cooling zone 105 for entering and exiting the cooling liquid are used for the function of the assembly auxiliary positioning device. The cooling zone 105 is a sealed space with a liquid inlet and outlet. The cooling liquid in the cooling zone 105 is made to flow in one direction.

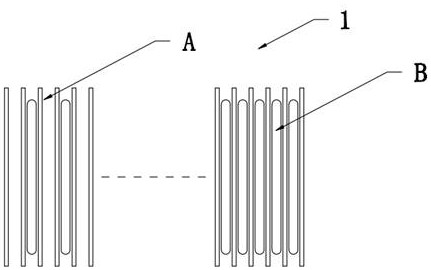

[0035] The liquid-cooled stacked battery assembly 1 is divided into a fast cooling zone A close to the liquid cooling source and a slow cooling zone B far away from the liquid cooling source; for example figure 2 As shown in the figure, the rectangular plates arranged therein are regarded as single cells, the components embedded between the single cells are the cooling zone 105, and the left side of the liquid-cooled stacked battery assembly 1 (near the liquid cooling source) is the rapid cooling zone A, The right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com