A ccd camera refrigeration device based on thermoelectric refrigeration

A refrigeration device and thermoelectric refrigeration technology, applied in the field of photoelectric detection, can solve the problems of easy condensation, reaching sub-zero temperature, poor heat dissipation at the hot end, etc., and achieve the effect of low noise and strong signal output capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

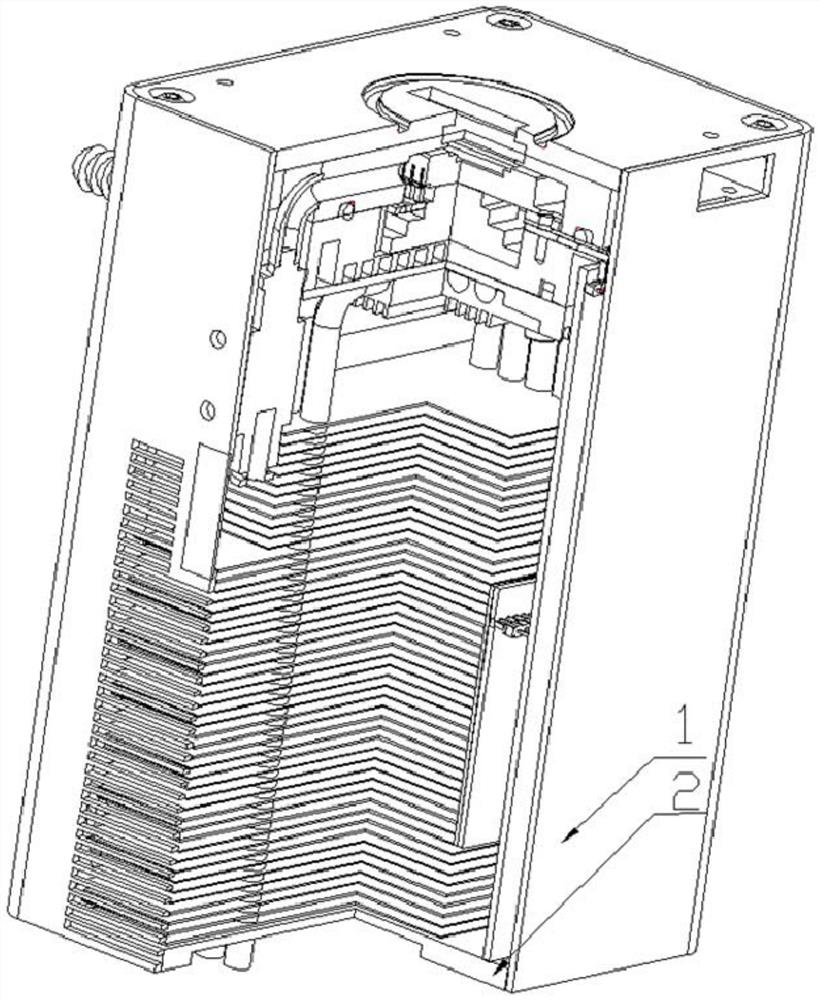

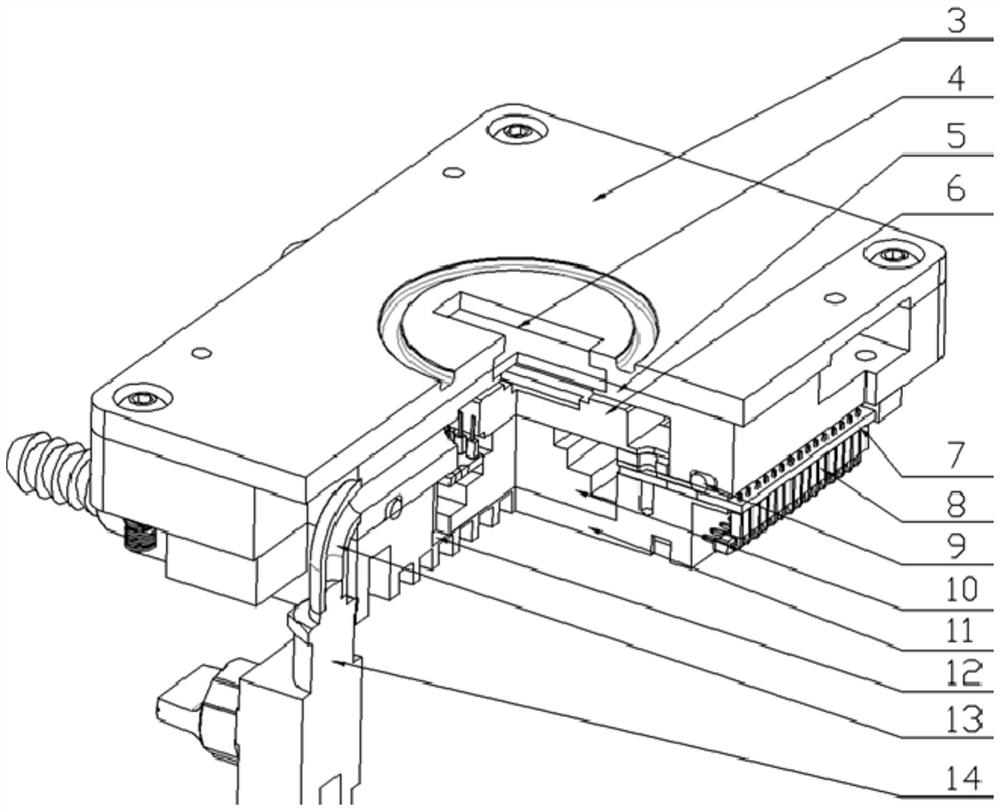

[0028] Specific implementation mode one: as Figure 1~5 As shown, the CCD camera cooling device based on thermoelectric cooling in this embodiment includes a camera cooling housing, a cooling sealing system, an air cooling structure and a signal output device, and the cooling sealing system, air cooling structure and signal output device are all arranged in the camera cooling housing in vivo,

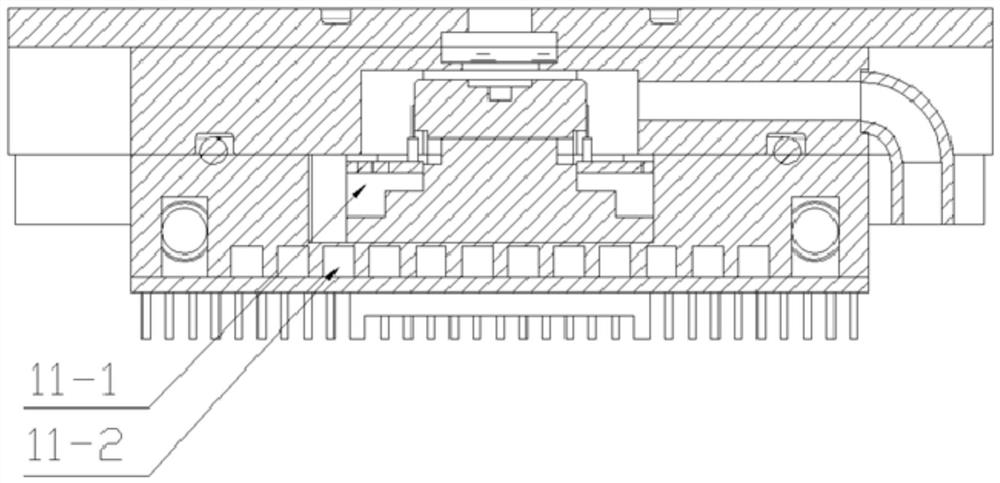

[0029] The refrigeration sealing system includes a refrigeration cavity 5 and a water-cooled plate 11. An optical window 4 is arranged at the center of the upper end of the refrigeration cavity 5. The refrigeration sealing system also includes a CCD signal adapter plate 7, a temperature sensor 12, a thermoelectric cooling sheet 10 and a water-cooled cover. Plate 16, CCD camera 6 is attached to the cold end of thermoelectric cooling plate 10, the upper end surface of water cooling plate 11 is concave cavity structure 11-1, and several flow channels 11-2 are processed on water cooling pla...

specific Embodiment approach 2

[0032] Specific implementation mode two: as figure 1 and figure 2 As shown, the camera refrigeration housing in this embodiment includes a packaging cylinder 1, a bottom plate 2 and an upper cover 3, the upper cover 3 is installed on the upper end surface of the packaging cylinder 1 by bolts, and the bottom plate 2 is installed on the lower end surface of the packaging cylinder 1 Above, the center of the upper cover 3 is processed with an optical window 4 .

[0033] In such a design, the packaging cylinder 1, the bottom plate 2 and the upper cover 3 realize the external packaging of the entire CCD camera cooling device. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0034] Specific implementation mode three: as figure 1 and figure 2 As shown, the optical window 4 of this embodiment is sealed with epoxy resin.

[0035]With such a design, since the cooling temperature inside the cooling chamber 5 reaches negative temperature, the cooling chamber must be sealed and the internal water vapor must be discharged. At the same time, the cooling chamber 5 is filled with nitrogen or vacuumized to prevent water vapor from being liquefied at low temperature and destroying the CCD. The camera works normally, and the TEC cooling effect is better in the vacuum environment. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com