an electromagnetic cooking appliance

A cooking utensil and electromagnetic technology, applied in the field of kitchen utensils, can solve the problems of limited improvement of thermal energy efficiency utilization rate, limited improvement of thermal energy efficiency utilization rate, and small proportion of heat radiation, so as to improve the utilization rate of "recycling", heat The effect of improving energy efficiency utilization and reducing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

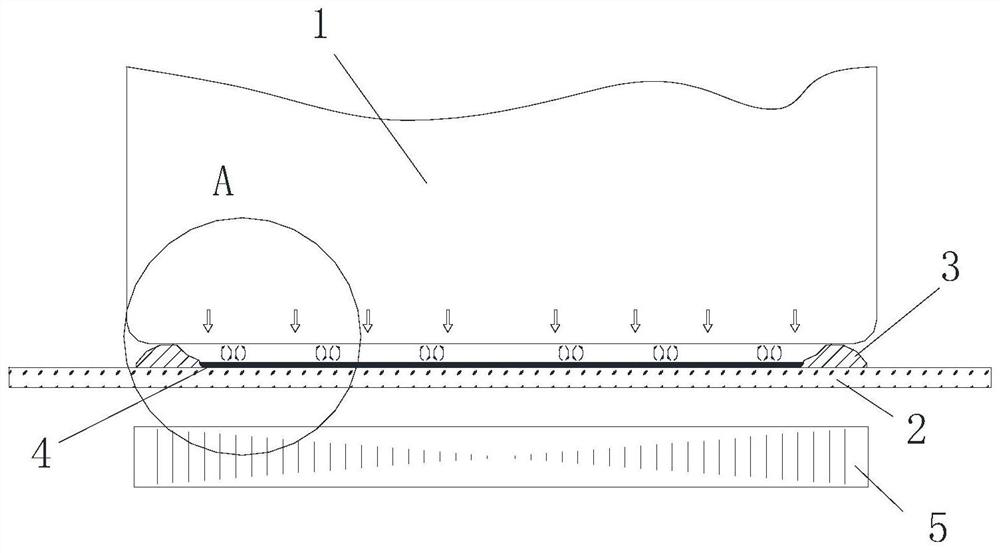

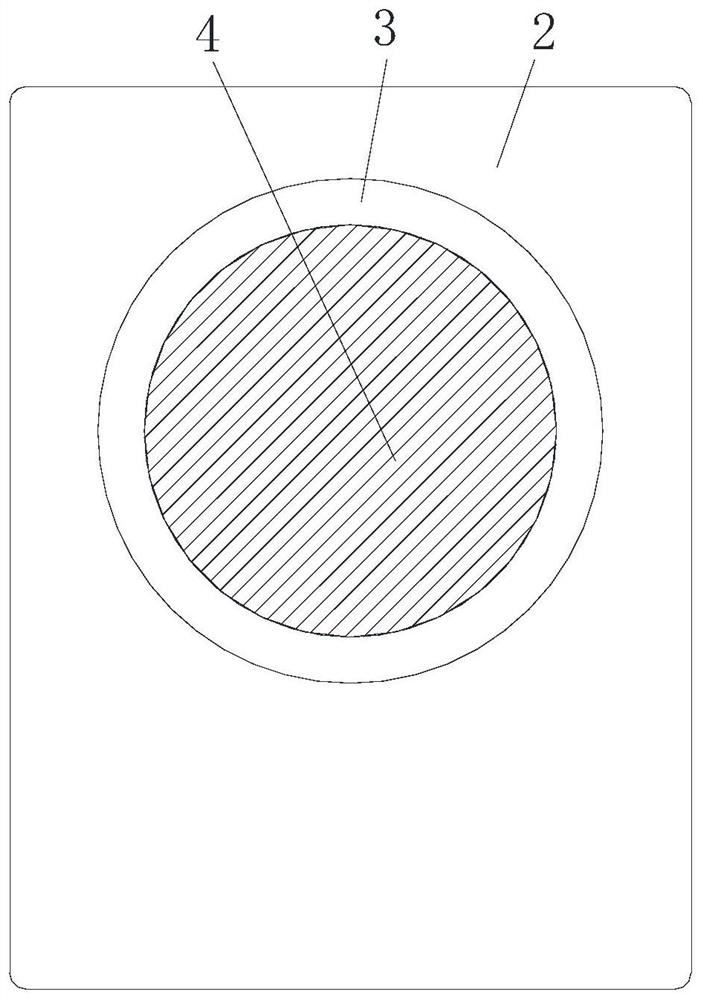

[0054] like Figure 1 to Figure 3 As shown, the boss 3 is in the form of a closed ring, and the top of the boss 3 has a sealing part, so that the bottom edge of the pot 1 placed on the panel 2 and the boss 3 are sealed and fit. The lower surface of the boss 3 is in sealing contact with the panel 2 to form a closed air chamber 9 between the panel 2 and the cookware 1 . The existence of the closed air chamber isolates the hot air in the closed air chamber 9 from the outside air, so that there is no large-scale convective heat exchange between the inside and outside air, and a large amount of heat from the bottom of the pot 1 is prevented from being quickly lost. This embodiment suppresses heat loss from the three levels of "conduction", "radiation" and "heat exchange", greatly reduces heat loss, improves the cooking efficiency of the electromagnetic cooking utensil, and reduces the consumption of heat to the cooking utensil. The heat radiation inside the appliance reduces the t...

Embodiment approach 2

[0060] The structure and principle of this embodiment are basically the same as the above-mentioned first embodiment, the difference is: Figure 4 and Figure 5 As shown, the outer surface of the heating zone is provided with a plurality of the bosses 3, the plurality of the bosses 3 are arranged at intervals, and among the two adjacent bosses 3, the boss 31 located on the inner side has a lower height At the height of the bosses 32 located on the outer side or flush with each other. In this embodiment, the bosses 31 located on the inner side can be adapted to the pans 11 with a smaller bottom diameter, and the bosses 32 located on the outer side can be adapted to the pans 12 with a larger bottom diameter, thereby enhancing the application range of the electromagnetic cooking utensils . The heights of the inner and outer bosses are set to avoid the influence on the support of the large-sized pot 1 due to the inner boss 31 being higher than the outer boss 32 .

[0061] Altho...

Embodiment approach 3

[0063]Similar to Embodiment 2, a plurality of the bosses 3 are provided on the outer surface of the heating zone in this embodiment, and the plurality of bosses 3 are arranged at intervals. However, this embodiment is significantly different from the above-mentioned first and second embodiments in that: Image 6 As shown, the plurality of bosses 3 form a non-closed annular structure, that is, in this embodiment, when the cookware 1 is placed on the bosses 3, the cookware 1, the bosses 3 and the panel 2 Compared with the above two embodiments, a part of the heat radiated from the bottom of the cookware 1 in this embodiment will pass through the two connected chambers. The boss 3 is dissipated to the outside, resulting in a certain heat loss. Therefore, the thermal energy efficiency utilization rate of this embodiment will be reduced to a certain extent compared with the above-mentioned first and second embodiments. However, it has been verified that this embodiment Compared wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com