Unprotected open cut excavation subway station shield launching and receiving end backfill and reinforcement method

A technology for subway station and grading excavation, which is applied to filling, underwater structures, infrastructure engineering, etc., and can solve problems such as long construction period, cumbersome procedures, and difficulty in controlling the quality of backfill reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

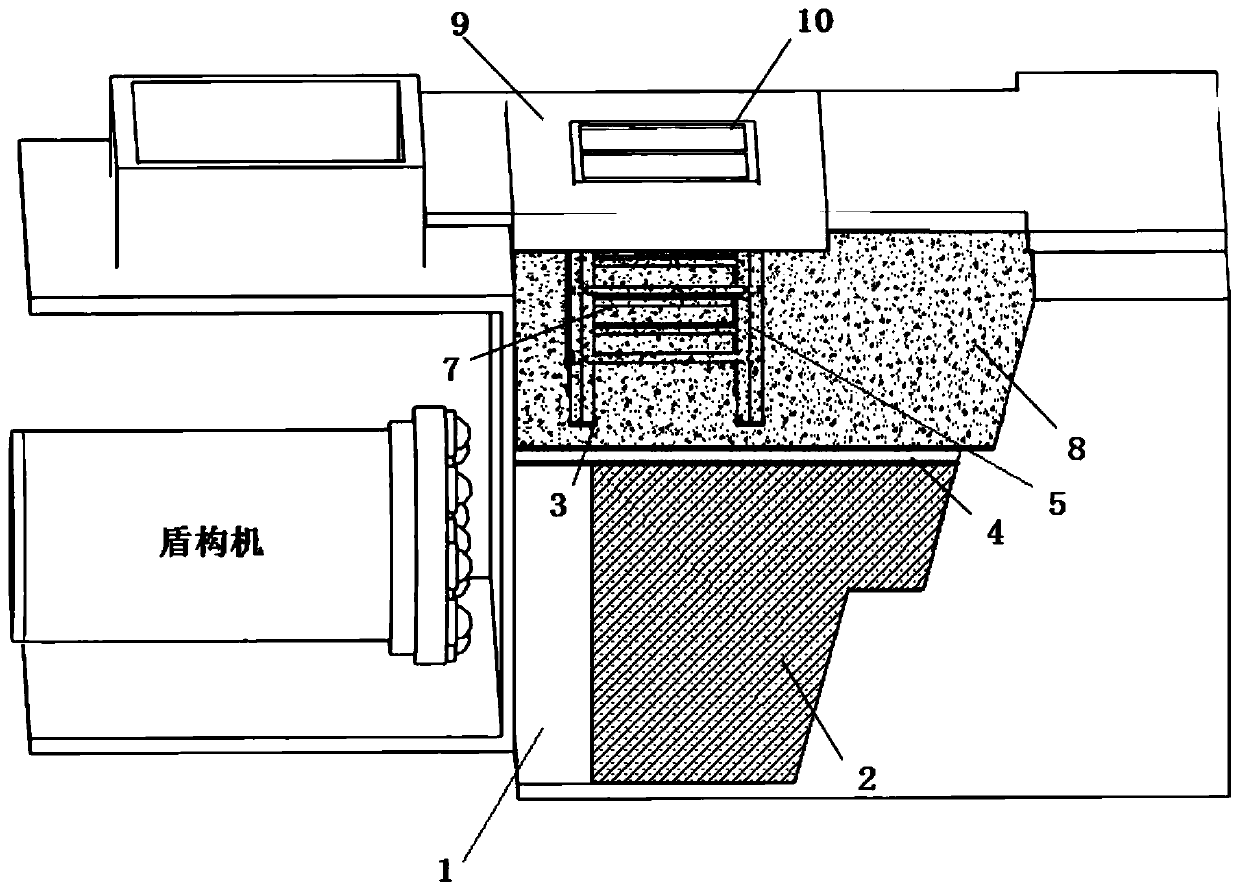

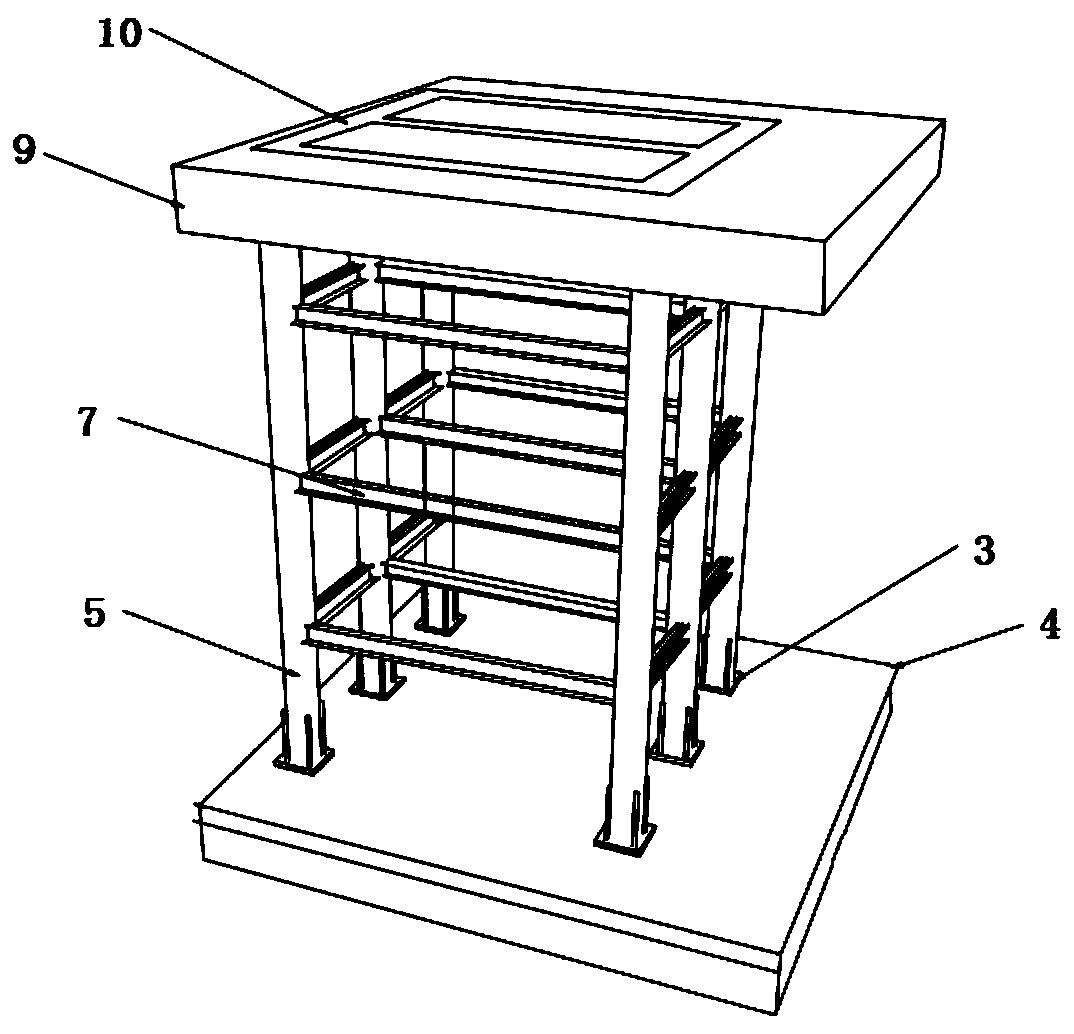

[0024] combined with Figure 1~4 , the method for backfilling and reinforcing the starting and receiving ends of shield tunnels in grading excavation for subway stations includes the following steps:

[0025] (1) Backfill range measurement: carry out actual measurement to determine the backfill range;

[0026] (2) Backfill in the portal area: at the end of the foundation pit, backfill in different areas, specifically, backfill plain concrete 1 with one tunnel diameter along the tunnel direction, backfill cement soil 2 with one tunnel diameter to the foot of the slope, and fill to the 1m above the entrance;

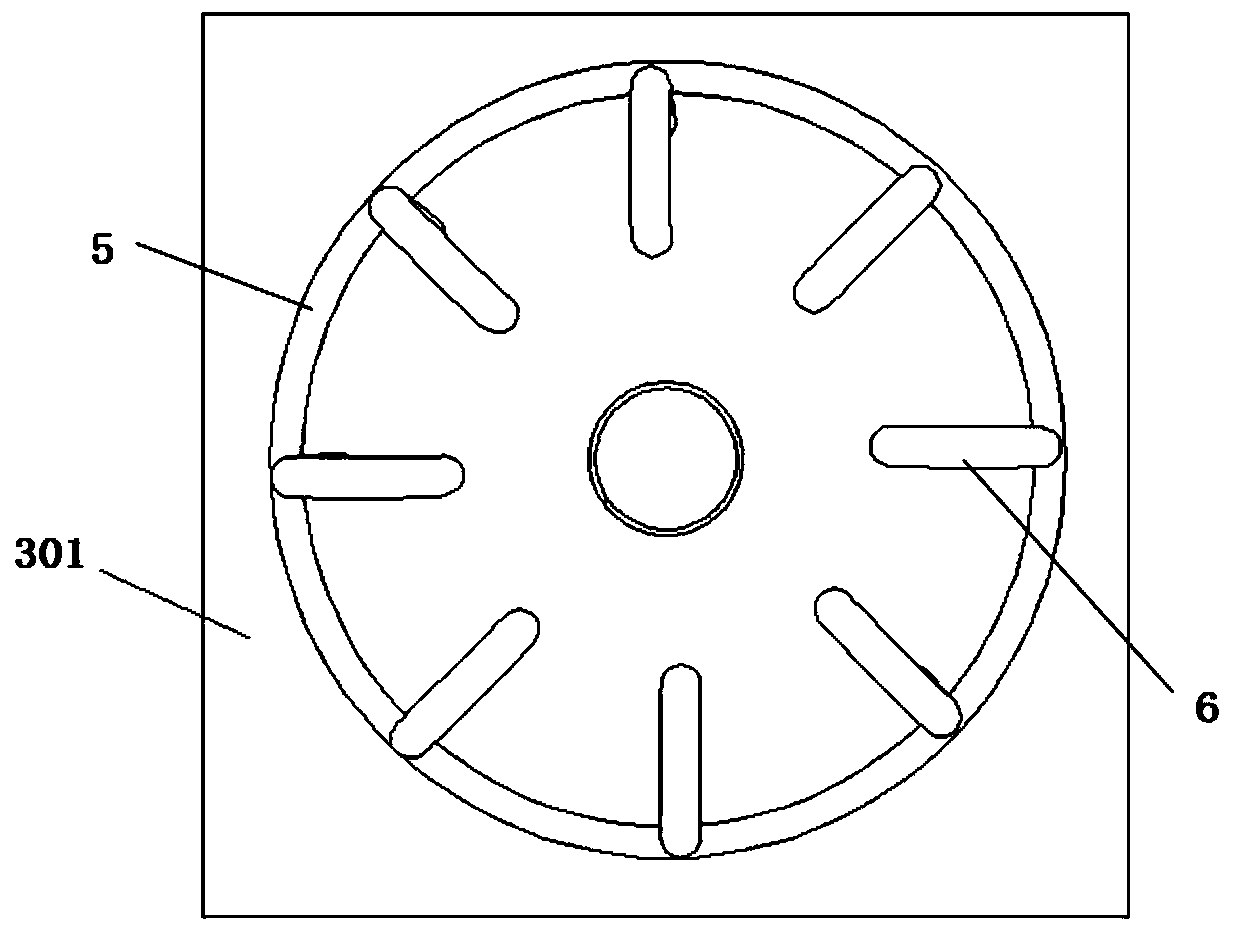

[0027] (3) Manufacture and installation of steel pipe pile embedded parts: after backfilling the end area, install the embedded part 3 along the preset position. The embedded part 3 includes a square steel plate 301, and several L Type steel bar 302;

[0028] (4) Anti-floating pressure plate construction: pour a cushion on the surface of the backfill, and bind the steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com