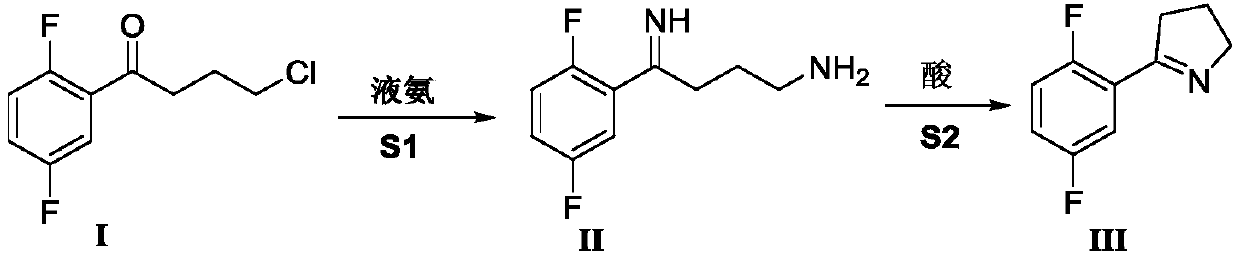

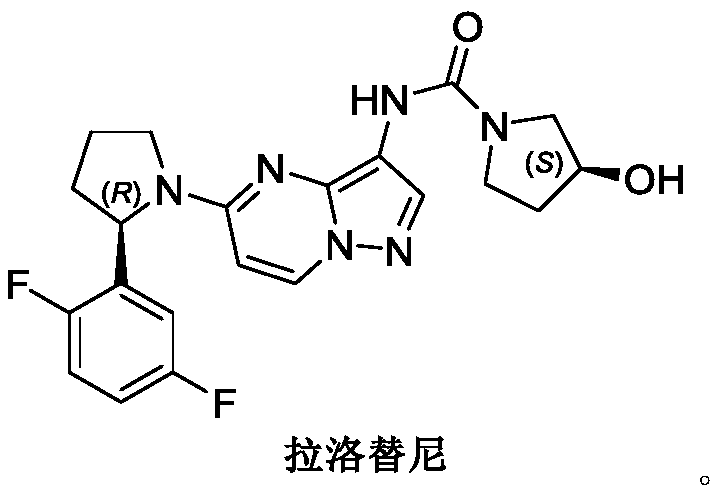

Synthesis method of larotrectinib intermediate

A synthetic method and intermediate technology, applied in the field of drug synthesis, can solve the problems of difficulty in product purification and difficult removal of triphenylphosphine oxide, and achieve the effects of reduced production costs, easy availability of raw materials, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

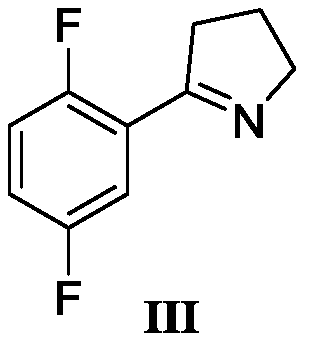

[0026] Add 50g of 4-chloro-1-(2,5-difluorophenyl)butan-1-one (1eq) (purchased from Shanghai Haohong Biomedical Technology Co., Ltd.) into a 500mL autoclave, add 200mL of tetrahydrofuran, and pass Add liquid ammonia, maintain the pressure of the reaction system at 0.4 MPa, react at 55°C for 4 hours, cool to room temperature 20-25°C, add 25mL of water under normal pressure, then slowly add formic acid dropwise, adjust the pH to 4.0, and continue stirring at room temperature for 4-5 hours , concentrate the solvent, add water 100mL and 150mL ethyl acetate to extract, separate layers, wash the organic phase with water once, dry, and concentrate to obtain a colorless or light yellow oil, namely 5-(2,5-difluorophenyl)-3, 4-Dihydro-2H-pyrrole (III), the two-step total yield is 93%, and the gas phase purity is 98.5%.

Embodiment 2

[0028] Add 50g of 4-chloro-1-(2,5-difluorophenyl)butan-1-one (1eq) (purchased from Shanghai Haohong Biomedical Technology Co., Ltd.) into a 500mL autoclave, add 250mL of ethanol, and pass Add liquid ammonia, maintain the pressure of the reaction system at 0.5 MPa, react at 60°C for 4 hours, cool to room temperature 20-25°C, add 25mL of water under normal pressure, then slowly add formic acid dropwise, adjust the pH to 3.5, and continue stirring at room temperature for 4-5 hours , concentrate the solvent, add water 100mL and 150mL ethyl acetate to extract, separate layers, wash the organic phase with water once, dry, and concentrate to obtain a colorless or light yellow oil, namely 5-(2,5-difluorophenyl)-3, 4-Dihydro-2H-pyrrole (III), the two-step total yield is 92%, and the gas phase purity is 98.2%.

Embodiment 3

[0030] Add 50g of 4-chloro-1-(2,5-difluorophenyl)butan-1-one (1eq) (purchased from Shanghai Haohong Biomedical Technology Co., Ltd.) into a 500mL autoclave, add 250mL of ethanol, and pass Add liquid ammonia, normal pressure, react at 60°C for 4 hours, and the liquid phase control shows no reaction.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap