a gamma-c 2 s activation modification method

A modification and compound technology, applied in the field of activation modification of γ-C2S, can solve the problem of low product strength, and achieve the effect of increasing specific surface area, increasing carbonization degree, and increasing compactness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] a gamma-C 2 The activation modification method of S comprises the following steps:

[0028] 1) Put 296g of calcium hydroxide and 120g of silicon dioxide into a ball milling tank and mix them, then add 3mol.% barium hydroxide, and ball mill and mix them for 2 hours at a ball milling speed of 200rpm to obtain raw materials for firing;

[0029] 2) Take out the calcined raw materials and add 10% alcohol to mix them, press them into tablets, and bake them at 60°C for 24 hours to fully dry them. Raise the temperature to 1400°C and keep it warm for 3 hours, then cool down to room temperature naturally with the furnace to obtain metal ion-doped γ-C 2 S.

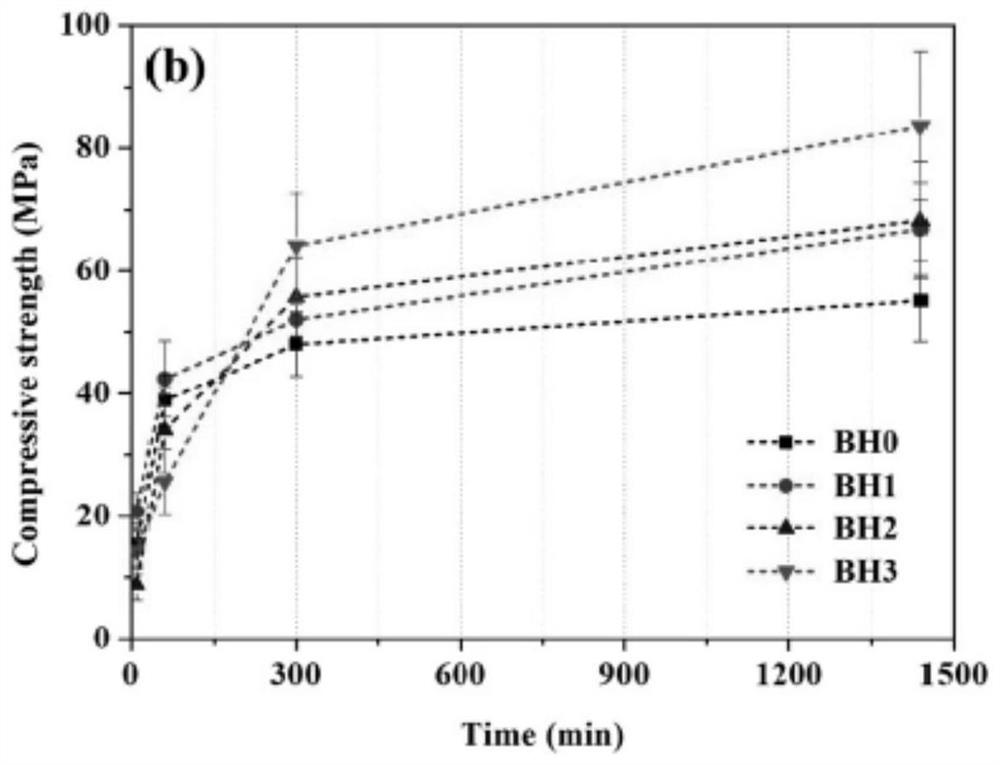

[0030] The γ-C doped with the metal ions of this embodiment 2 S is carbonized and cured to obtain γ-C 2 S carbonized products, according to GB / T50081-2002 "Standard for Test Methods of Mechanical Properties of Ordinary Concrete" for γ-C 2 The mechanical properties of S carbonized products are tested, and the test results ...

Embodiment 2

[0033] a gamma-C 2 The activation modification method of S comprises the following steps:

[0034] 1) Put 296g of calcium hydroxide and 120g of silicon dioxide into a ball milling tank and mix them, then add 2mol.% barium hydroxide, and ball mill and mix them for 2 hours at a ball milling speed of 200rpm to obtain raw materials for firing;

[0035] 2) Take out the calcined raw materials and add 10% alcohol to mix them, press them into tablets, and bake them at 60°C for 24 hours to fully dry them. Raise the temperature to 1400°C and keep it warm for 3 hours, then cool down to room temperature naturally with the furnace to obtain metal ion-doped γ-C 2 S.

[0036] The γ-C doped with the metal ions of this embodiment 2 S is carbonized and cured to obtain γ-C 2 S carbonized products, according to GB / T50081-2002 "Standard for Test Methods of Mechanical Properties of Ordinary Concrete" for γ-C 2 The mechanical properties of S carbonized products are tested, and the test results ...

Embodiment 3

[0039] a gamma-C 2 The activation modification method of S comprises the following steps:

[0040] 1) Put 296g of calcium hydroxide and 120g of silicon dioxide into a ball milling tank and mix them, then add 1mol.% barium hydroxide, and ball mill and mix them for 2 hours at a ball milling rate of 200rpm to obtain raw materials for firing;

[0041] 2) Take out the calcined raw materials and add 10% alcohol to mix them, press them into tablets, and bake them at 60°C for 24 hours to fully dry them. Raise the temperature to 1400°C and keep it warm for 3 hours, then cool down to room temperature naturally with the furnace to obtain metal ion-doped γ-C 2 S.

[0042] The γ-C doped with the metal ions of this embodiment 2 S is carbonized and cured to obtain γ-C 2 S carbonized products, according to GB / T50081-2002 "Standard for Test Methods of Mechanical Properties of Ordinary Concrete" for γ-C 2 The mechanical properties of S carbonized products are tested, and the test results a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com