One-dimensional ultrasonic linear vibration turning device

A linear vibration and ultrasonic technology, used in turning equipment, auxiliary devices, large fixed members, etc., can solve the problems of complex equipment operation, reduce heat generation, reduce cutting force, etc., to improve dimensional accuracy, improve surface quality, reduce The effect of small shape errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention. Unless otherwise specified, the examples are all in accordance with conventional experimental conditions. In addition, for those skilled in the art, on the premise of not departing from the spirit and scope of the present invention, various modifications or improvements to the material components and dosages in these embodiments belong to the claims of the present invention. scope.

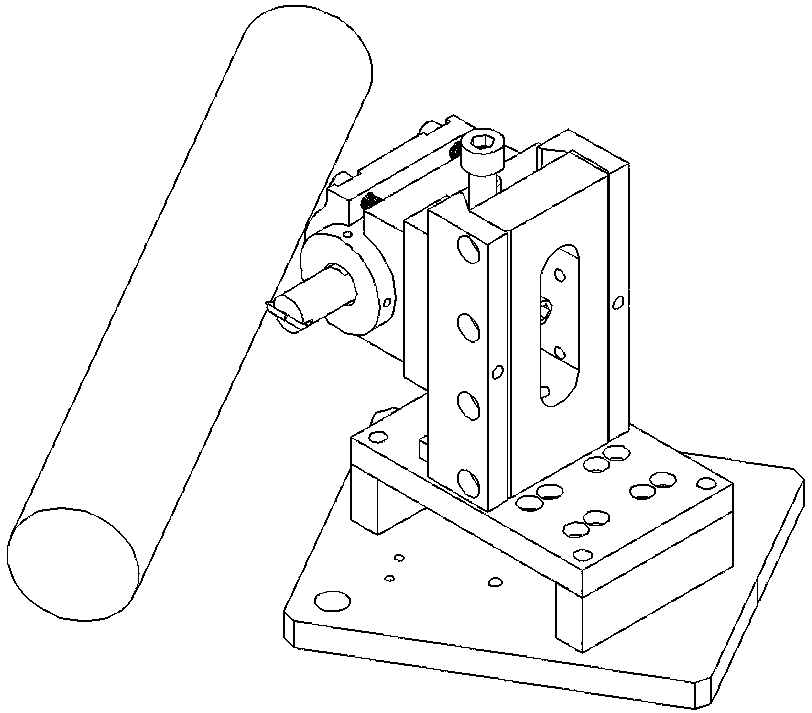

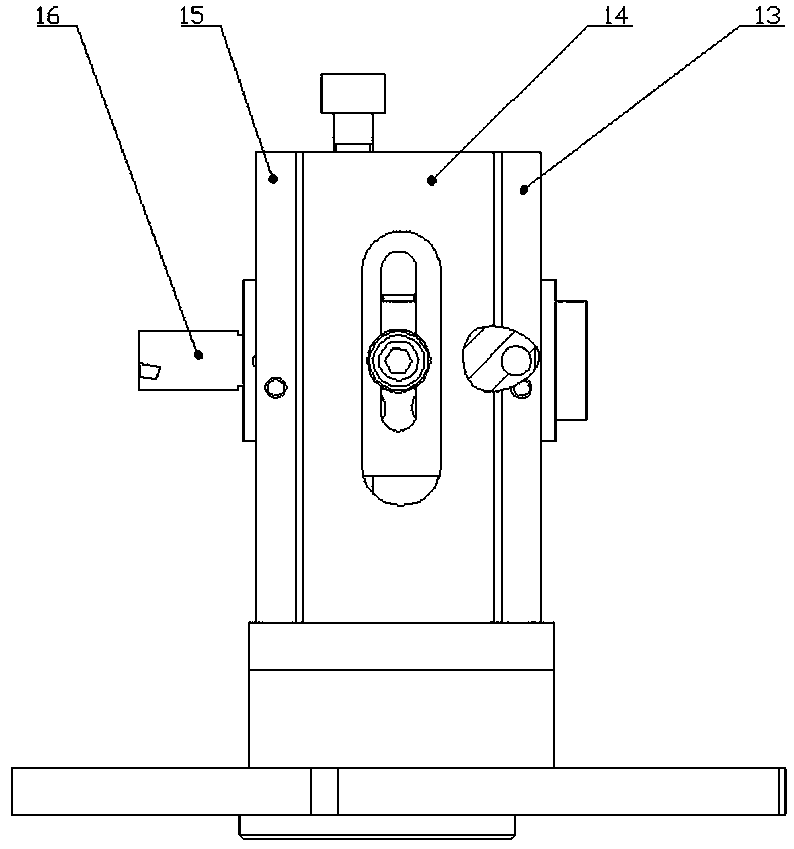

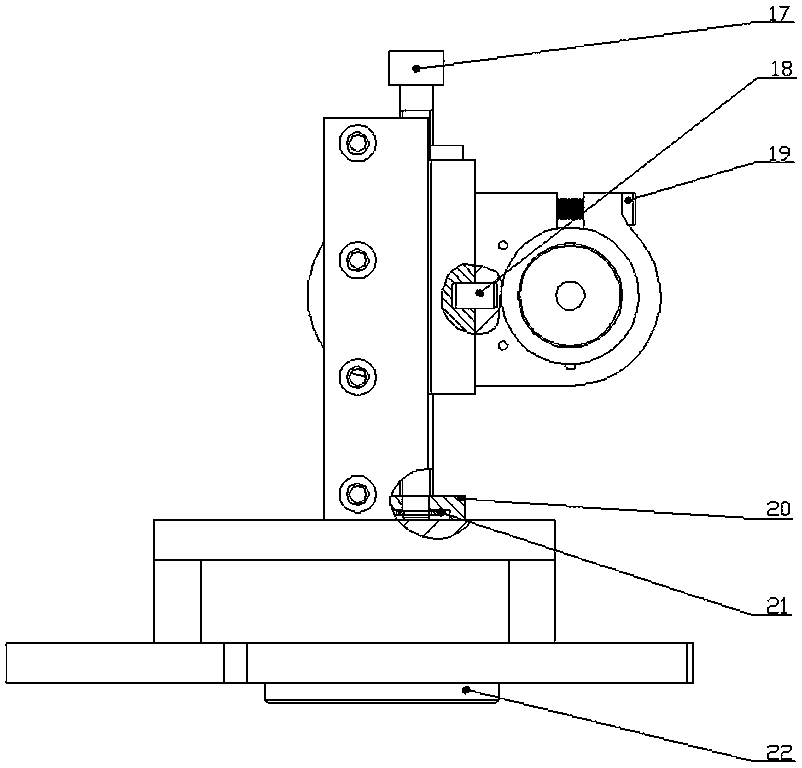

[0030] Such as Figure 1 to Figure 7 The shown one-dimensional ultrasonic linear vibration turning device includes a bottom plate 1, a clamping seat 7, a dovetail groove base 14 and a slider seat 23, wherein:

[0031] A central rotating block 22 is fixedly arranged below the core of the bottom plate 1, and a pit is arranged on the upper surface of the cutting station on the lathe, and the central rotating block 22 is correspondingly installed in the pit. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com