Water penetrating cooling gas seal device

A water-penetrating cooling and air-sealing technology, applied in workpiece cooling device, drying gas arrangement, lighting and heating equipment, etc., can solve the problems of long construction time, unbalanced spinning head deformation, long processing cycle, etc. The effect of avoiding process and equipment accidents and short construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with embodiment the present invention is described in further detail:

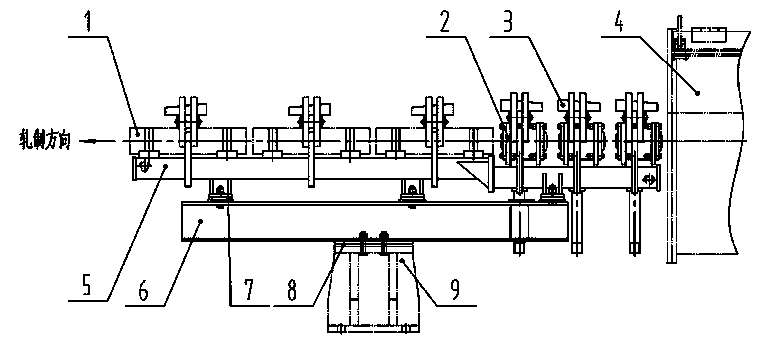

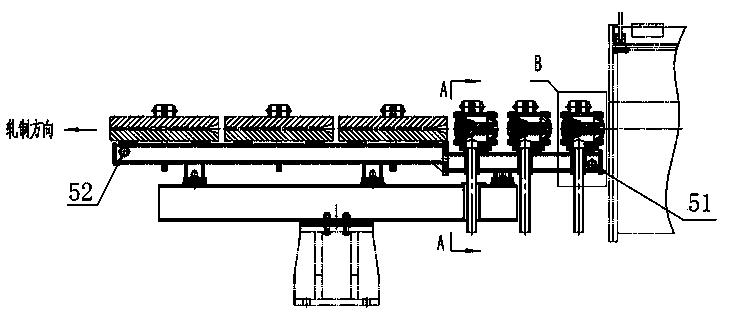

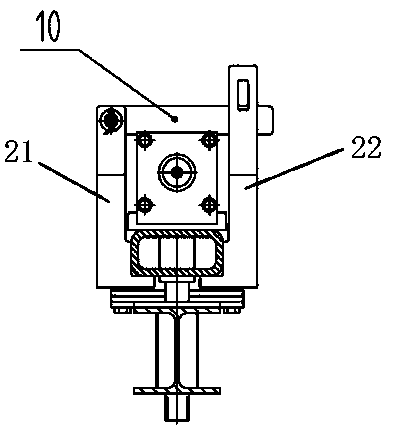

[0026] Such as Figure 1 to Figure 4 As shown, the water-piercing cooling air seal device of the present invention is located close to the back of the water-piercing cooling water cooling box 4, and includes a composite water beam 5, a beam 6, a base 9 and an air seal nozzle assembly 2, and the beam 6 is installed on the base 9, a composite water beam 5 is installed on the beam 6, the front end of the composite water beam 5 is provided with a circulating water inlet 51, and the rear end is provided with a circulating water outlet 52, and the composite water beam 5 is cooled by circulating water to prevent thermal deformation. The rear end of the beam 5 is equipped with a water-through cooling dry running tank 1, and the front end is equipped with a number of air seal nozzle assemblies 2. The compressed air inlet 15 connected to the intake pipe, and the position of the composite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com