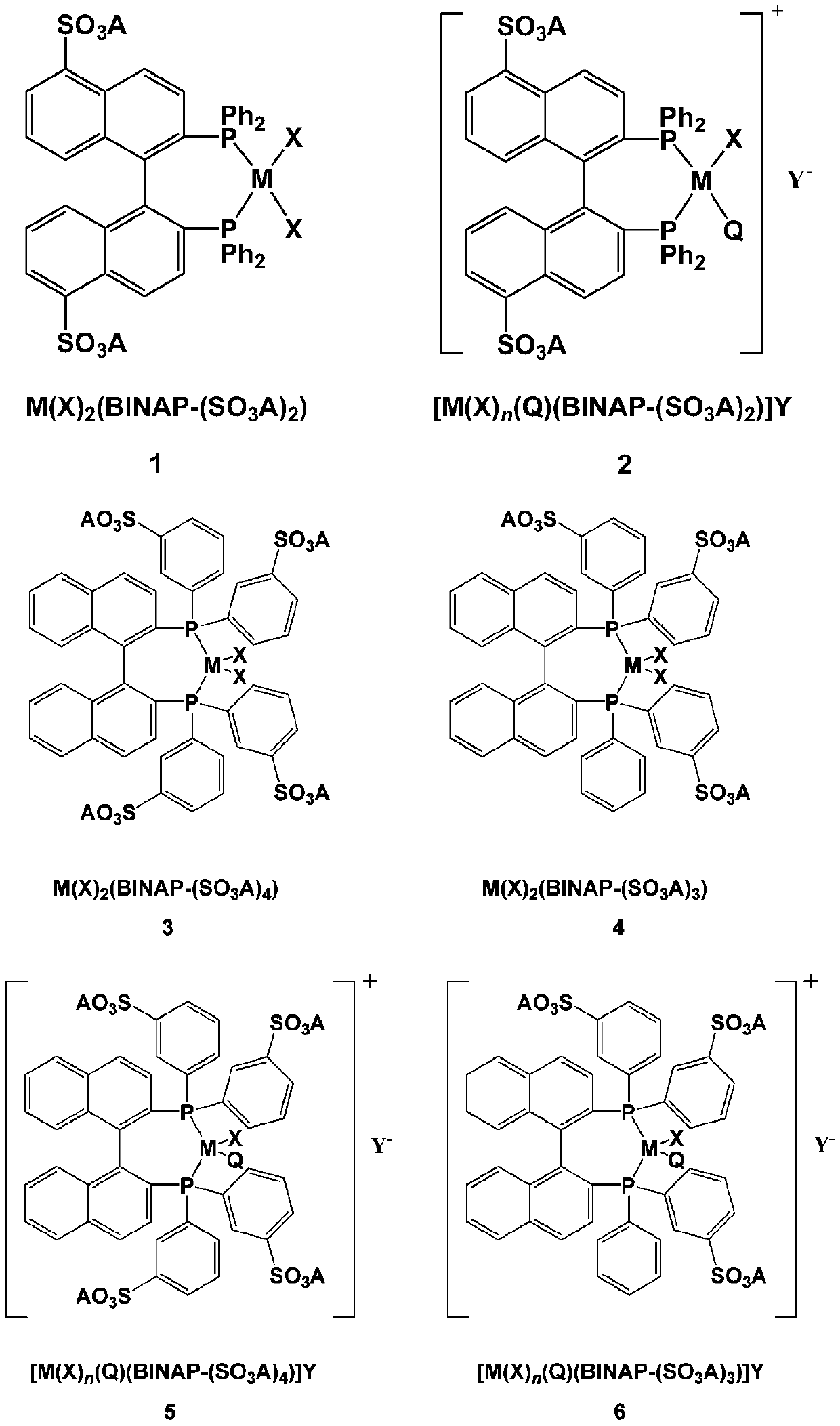

Application of sulfonated BINAP and polyether functionalized ionic liquid integrated chiral catalyst in asymmetric hydrogenation reaction

A technology of chiral catalysts and ionic liquids, applied in the field of chemistry and chemical engineering, can solve the problems of reduced catalytic efficiency, non-conformity with green chemistry, waste of resources, etc., and achieve the effects of reduced negative effects, high stability, and low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Asymmetric Hydrogenation Catalyzed by Catalyst 1a-1 / Methyl Acetoacetate / Methanol System

[0036] Catalyst 1a-1 is Ru(Br) 2 (S-BINAP-(SO 3 A) 2 )(A=[Ph(OCH 2 CH 2 ) 16 IMCH 3 ] + ,m=16,l=0,R 1 =Ph,R 2 = CH 3 ). Under an argon atmosphere, add catalyst 1a-1, methyl acetoacetate and methanol into the autoclave, the molar ratio of catalyst 1a-1 and methyl acetoacetate is 1:1000, then at 60°C, 4.0MPa hydrogen pressure The reaction was carried out for 20 hours. After the reaction, methanol was removed under reduced pressure, and n-hexane was added for extraction. The upper organic phase was analyzed by gas chromatography (lipodex A25m×0.25mm chiral capillary column), the conversion rate of the substrate was 100%, and the ee (S) value was 98.4 %; The initial TOF value of the reaction measured by the pressure drop method is 2914h -1 ; The catalyst phase of the lower floor continues to add methyl acetoacetate and methyl alcohol after the two-phase separation, and carr...

Embodiment 2

[0038] Asymmetric Hydrogenation Catalyzed by Catalyst 1a-2 / Methyl Acetoacetate / Methanol System

[0039] Catalyst 1a-2 is Ru(Br) 2 (S-BINAP-(SO 3 A) 2 )(A=[Ph(OCH 2 CH 2 ) 70 IMCH 3 ] + ,m=16,l=0,R 1 =Ph, R 2 = CH 3 ). Under argon atmosphere, add catalyst 1a-2, methyl acetoacetate and methanol into the autoclave, the molar ratio of catalyst 1a-2 and methyl acetoacetate is 1:1000, and then at 60°C, 4.0MPa hydrogen pressure The reaction was carried out for 20 hours. After the reaction, the methanol was removed under reduced pressure, and n-heptane was added for extraction. The upper organic phase was analyzed by gas chromatography (lipodex A25m×0.25mm chiral capillary column), the conversion rate of the substrate was 100%, and the ee (S) value 98.2%; The initial TOF value of the reaction measured by the pressure drop method is 2868h -1 ; The catalyst phase of the lower floor continues to add methyl acetoacetate and methyl alcohol after the two-phase separation, and ca...

Embodiment 3

[0041] Asymmetric Hydrogenation Catalyzed by Catalyst 1a-3 / Methyl Acetoacetate / Methanol System

[0042] Catalyst 1a-3 is Ru(Br) 2 (S-BINAP-(SO 3 A) 2 )(A=[n-C 12 h 25 (OCH 2 CH 2 ) 16 IMCH 3 ] + ,m=16,l=0,R 1 = n-C 12 h 25 , R 2 =CH 3 ). Under argon atmosphere, add catalyst 1a-3, methyl acetoacetate and methanol into the autoclave, the molar ratio of catalyst 1a-3 and methyl acetoacetate is 1:10000, and then at 80°C, 4.0MPa hydrogen pressure The reaction was carried out for 72 hours. After the reaction, methanol was removed under reduced pressure, and n-heptane was added for extraction. The upper organic phase was analyzed by gas chromatography (lipodex A 25m×0.25mm chiral capillary column), the substrate conversion rate was 95%, ee(S) Value 96.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com