Grounding connection structure of gas spray header in plasma processing device

A gas shower head and plasma technology, applied in the field of plasma treatment, can solve problems such as unstable conduction effect, shortened service life of bolts, uneven distribution of plasma, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

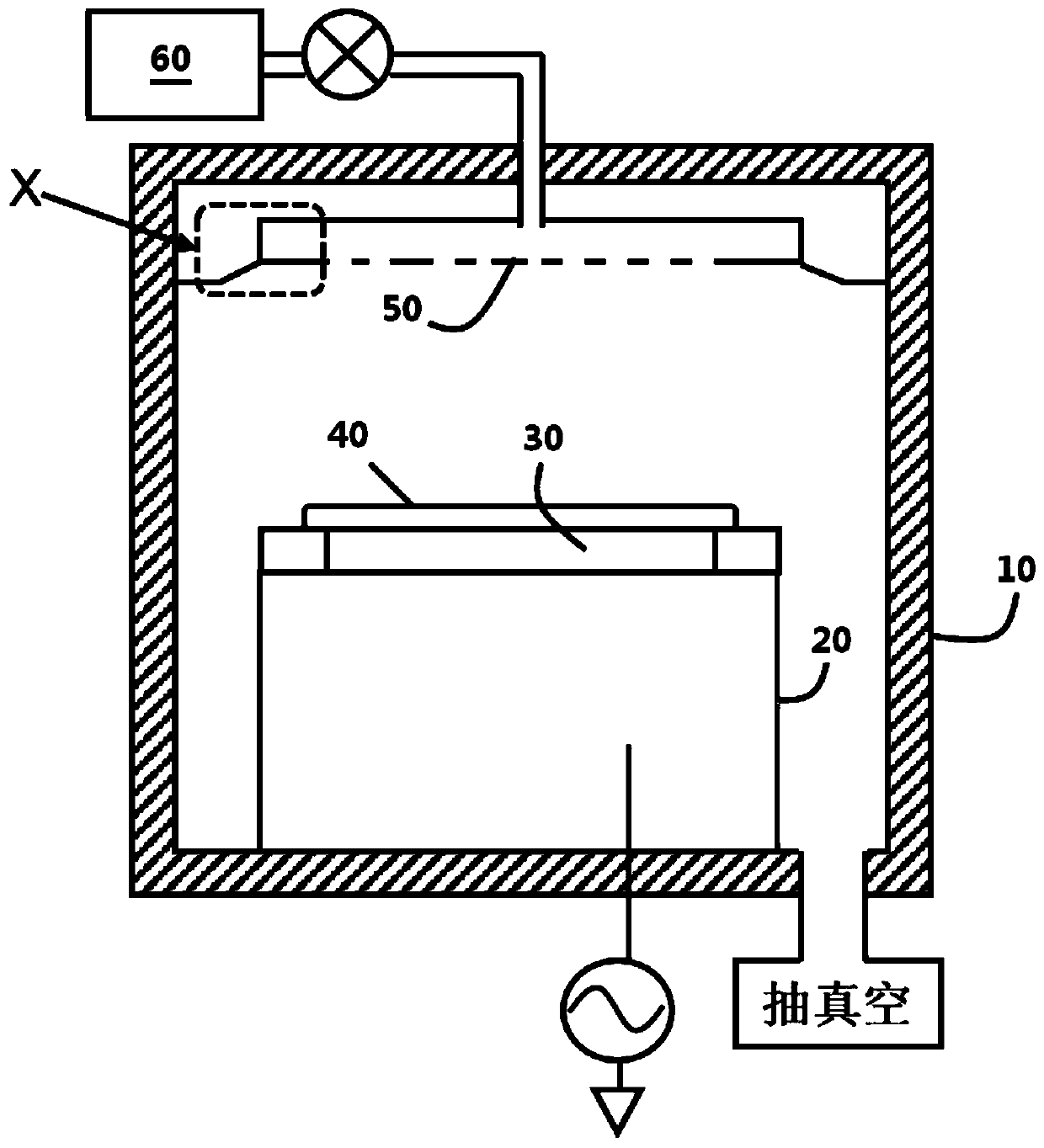

[0034] figure 1 Shown is a capacitively coupled plasma processing device, including a vacuumable reaction chamber 10, a substrate support base 20 is arranged below the reaction chamber 10, and the substrate is fixed by an electrostatic chuck 30 on the substrate support base 20 40. The substrate support base 20 is usually applied with at least one radio frequency power source as the lower electrode, and by coupling the radio frequency power into the reaction chamber 10, the gas delivered by the gas supply device 60 into the reaction chamber 10 is dissociated into plasma, The processing of the substrate 40 is realized.

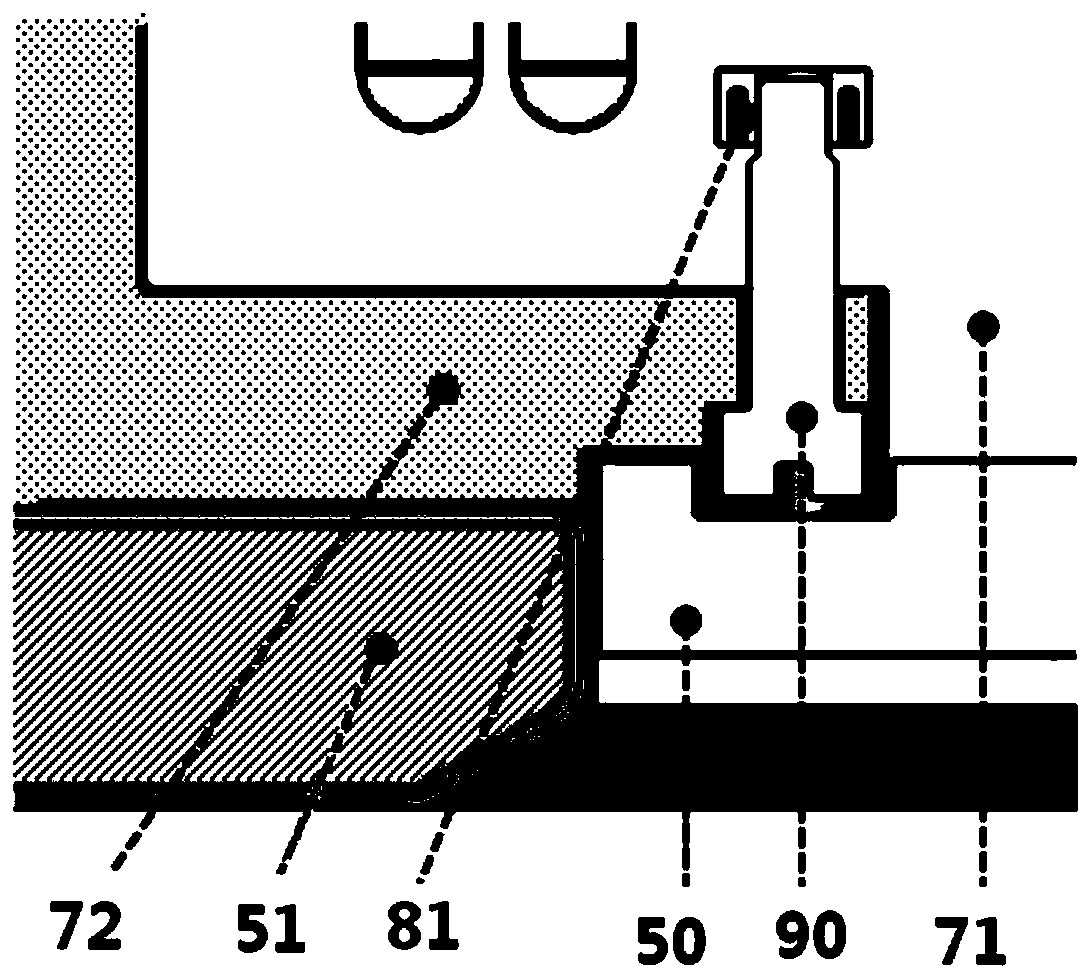

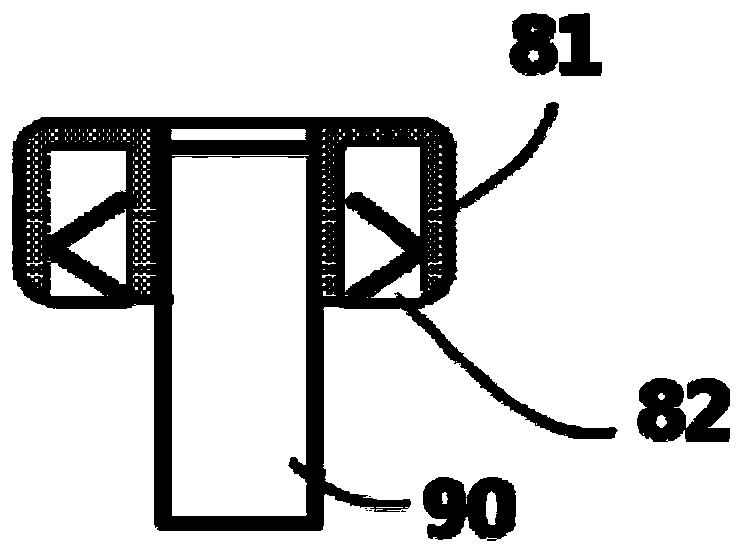

[0035]The reaction gas output by the gas supply device 60 is evenly transported into the reaction chamber 10 through the vent holes distributed on a gas shower head 50; RF power signal coupled to the upper electrode. In order to form a radio frequency current loop, the gas shower head 50 is usually connected to a grounded mounting base on the top of the reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com