Preparation method of graphene-loaded metal oxide electrode material

A technology for loading metals and electrode materials, applied in the fields of hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, hybrid capacitor current collectors, etc., can solve the problems of unsuitability for large-scale applications, low production efficiency, and low spray rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

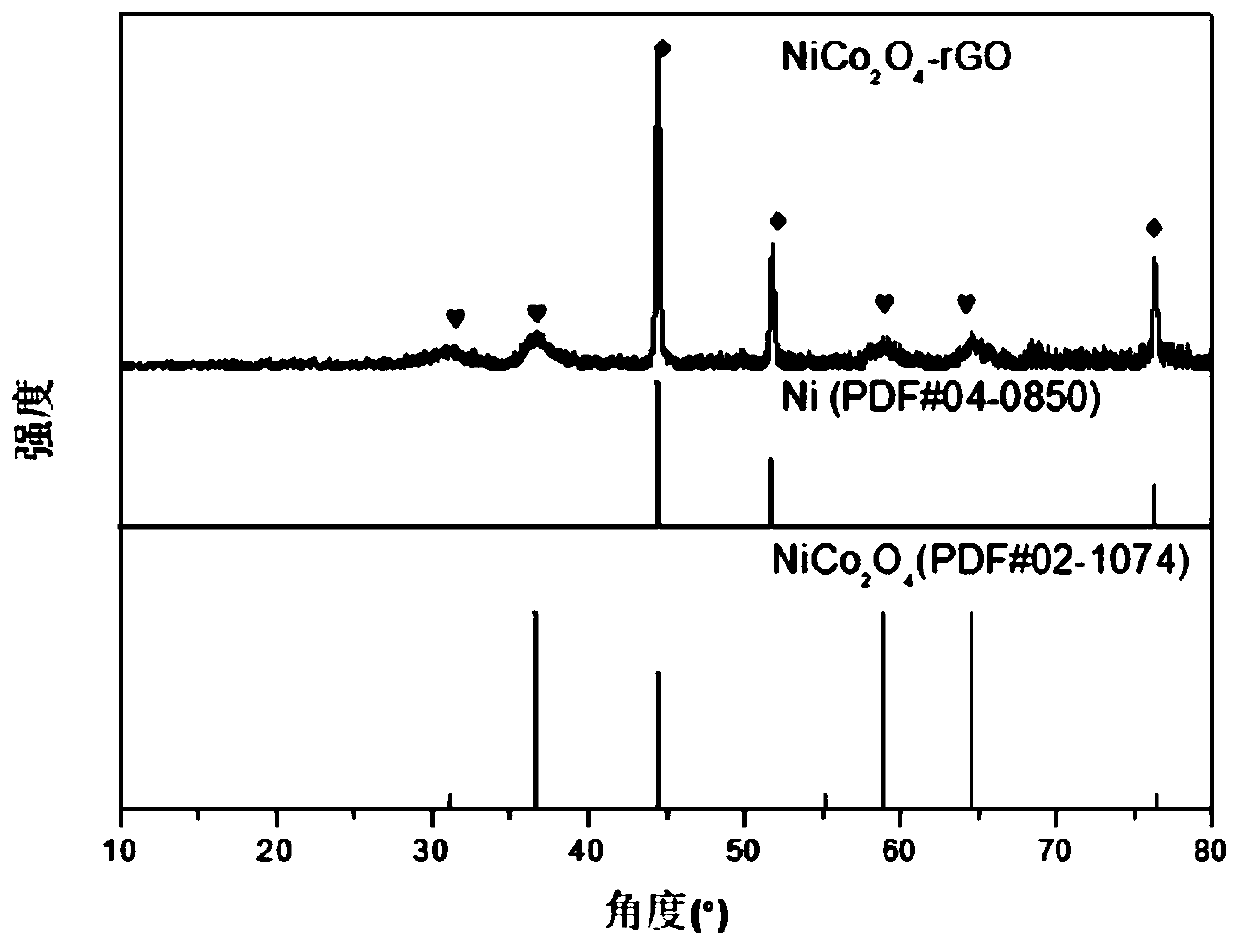

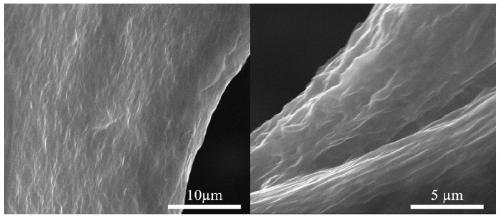

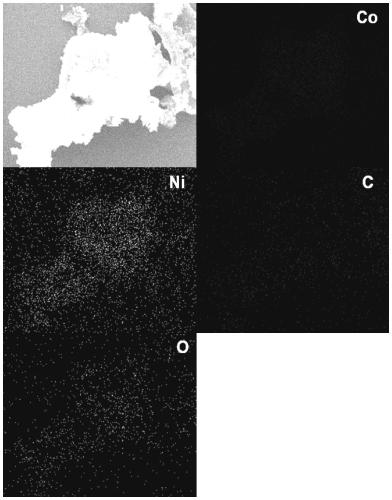

[0025] [Example 1] rGO / NiCo 2 o 4 Compound electrode

[0026] Step 1. Configuration of GO aqueous solution

[0027] 200 mL of GO aqueous solution with a concentration of 0.7 mg / mL was prepared with a GO raw material slurry with a concentration of 1 wt %;

[0028] Step 2. Preparation of precursor solution

[0029] Taking the mass ratio of GO to metal salt as 1:5 as an example, weigh 0.23g of Ni(NO 3 ) 2 ·6H 2 O and 0.46g of Co(NO 3 ) 2 ·6H 2 O was dissolved in 16mL of ethanol and 64mL of ethylene glycol, and then 200mL of the above-mentioned GO aqueous solution was added; mixed for 2h under the assistance of ultrasound to obtain a uniform precursor mixed solution;

[0030] Step 3. Sample Preparation

[0031] First, fix the nickel foam on the surface of the heating table and heat it to 400°C; after that, put the prepared precursor mixed solution into the syringe, and set the liquid feeding speed to 0.5mL / min, and the carrier gas pressure to 0.2MPa, adjust the power of...

Embodiment 2

[0039] [Example 2] rGO / NiFe 2 o 4 Compound electrode

[0040] Step 1. Configuration of GO aqueous solution

[0041] 200 mL of GO aqueous solution with a concentration of 0.1 mg / mL was prepared with a concentration of 1 wt % GO raw material slurry;

[0042] Step 2. Preparation of precursor solution

[0043] Taking the mass ratio of GO to metal salt as 1:10 as an example, weigh 0.47g of Ni(NO 3 ) 2 ·6H 2 O and 0.94g of Fe(NO 3 ) 2 9H 2 O was dissolved in 16 mL of ethanol and 64 mL of ethylene glycol, and then 200 mL of the above-mentioned GO aqueous solution was added, and mixed for 2 h under the assistance of ultrasound to obtain a uniform precursor mixed solution;

[0044] Step 3. Sample Preparation

[0045] First, fix the copper foam on the surface of the heating table and heat it to 350°C; after that, put the prepared precursor mixed solution into the syringe, and set the liquid feeding speed to 0.3mL / min, and the carrier gas pressure to 0.15MPa, adjust the power ...

Embodiment 3

[0047] [Example 3] rGO / CoO composite electrode

[0048] Step 1. Configuration of GO aqueous solution

[0049] 200 mL of GO aqueous solution with a concentration of 0.35 mg / mL was prepared with a GO raw material slurry with a concentration of 1 wt %;

[0050] Step 2. Preparation of precursor solution

[0051] Taking the mass ratio of GO and metal salt as 1:15 as an example, weigh 2.1g of Co(NO 3 ) 2 ·6H 2 O was dissolved in 80mL ethanol, and then 200mL of the above-mentioned GO aqueous solution was added, and mixed for 2h under the assistance of ultrasound to obtain a uniform precursor mixed solution;

[0052] Step 3. Sample Preparation

[0053] First, the cleaned copper foil was fixed on the surface of the heating table, and heated to 500 °C; after that, the prepared precursor mixed solution was filled into the syringe, and the liquid feeding speed was set to 0.1 mL / min. The air pressure is set to 0.1MPa, and the power of the ultrasonic atomizing nozzle is adjusted betwe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mass specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com