Synthesis method of GQDs modified ZnO composite nanostructure gas sensitive material for detecting dimethylamine gas

A synthesis method and nano-composite material technology are applied in the synthesis field of ZnO composite nano-structured gas-sensing materials, and can solve the problems of increasing the optimal working temperature of the sensor, unfavorable on-line detection for analysis and detection, complex sample pretreatment and detection procedures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

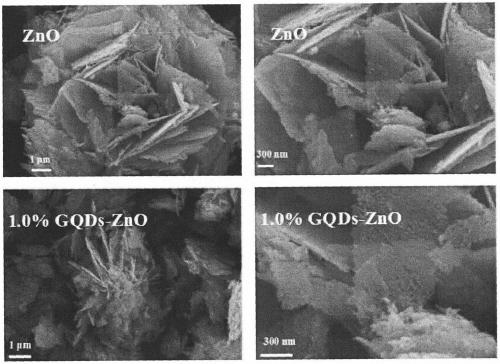

[0030] Synthesis of ZnO nanosheet gas sensitive materials:

[0031] 0.002mol ZnCl at room temperature 2 and 0.04mol of urea were sequentially added into 40mL of deionized water, slowly added into 1mL of dilute hydrochloric acid (5wt.%), and magnetically stirred for 1h. The above homogeneously mixed solution was transferred to a 50 mL polytetrafluoroethylene-lined stainless steel reaction kettle, and reacted in an electric blast drying oven at 80°C for 24 hours. After the reaction was completed, after cooling to room temperature naturally, the obtained white precipitate was alternately centrifuged with deionized water and absolute ethanol for 3 times, and then dried in an electric blast drying oven at 80°C for 12 hours to obtain a white powder; The powder was calcined in a box-type electric furnace at 350° C. (heating rate 5° C. / min) for 1 h to obtain ZnO nanosheets.

Embodiment 2

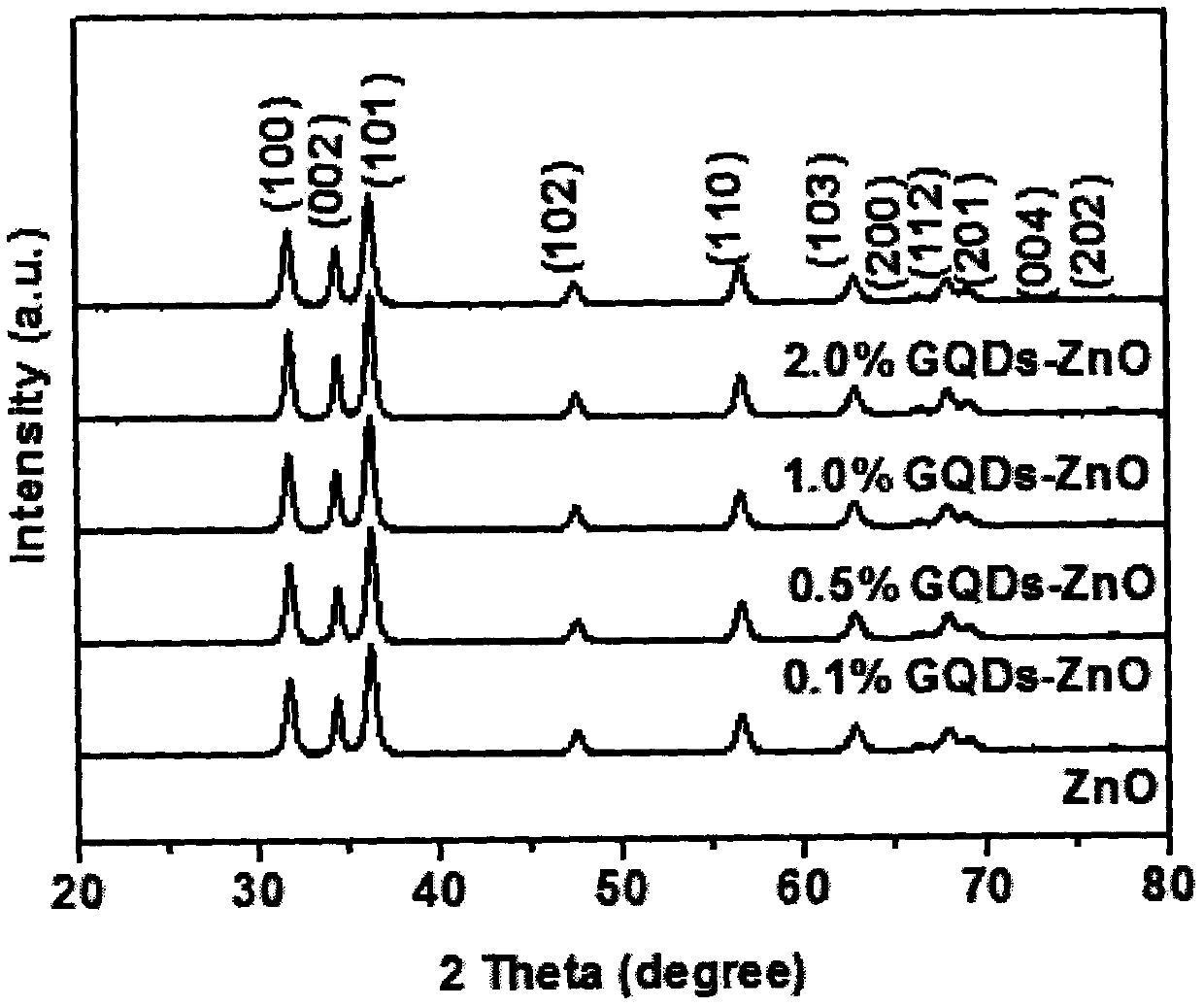

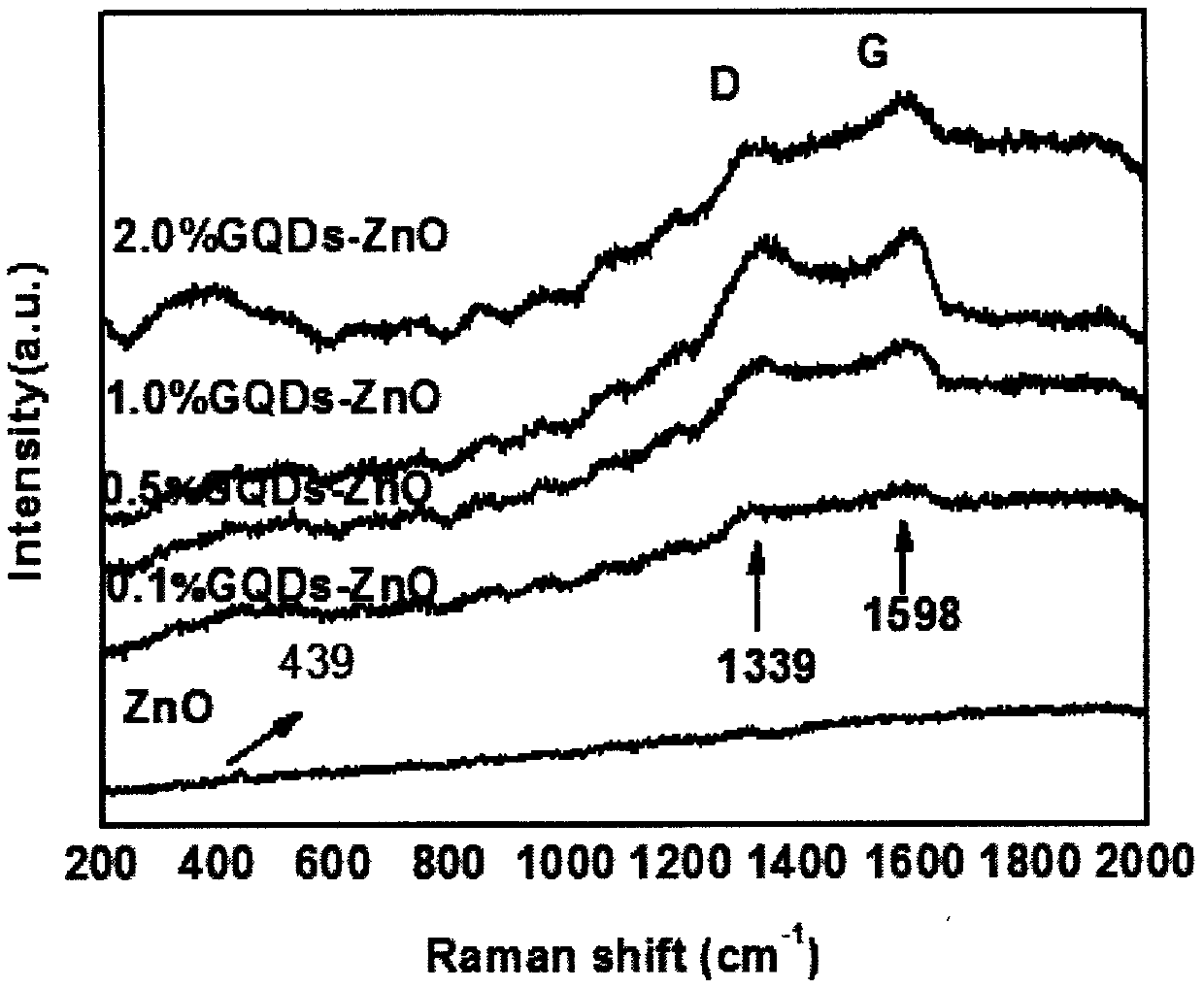

[0033] Synthesis of GQDs-modified ZnO composite nanostructure gas-sensing materials Gas-sensing materials:

[0034] Weigh 0.8g ZnO nanosheet powder and disperse it in 80mL deionized water, and divide it into 4 parts. Measure 0.2mL, 1.0mL, 2.0mL, and 4.0mL of graphene quantum dot dispersion liquid and add them to the above-mentioned ZnO dispersion liquid to obtain a mixed dispersion liquid of GQDs and ZnO, and ultrasonically treat it for 30 minutes to make it fully mixed. The mixed dispersion of GQDs and ZnO was stirred and evaporated at 60 °C in air until completely dry. The obtained samples were named as 0.1% GQDs-ZnO, 0.5% GQDs-ZnO, 1.0% GQDs-ZnO, 2.0% GQDs-ZnO. ZnO nanocomposite gas-sensing materials decorated with different proportions of GQDs can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com