Anticorrosive weather-resistant functional integrated water-based graphene coating and preparation method thereof

A water-based graphene and graphene powder technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve problems such as difficulty in meeting the requirements of ships

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

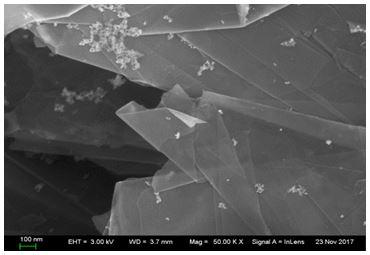

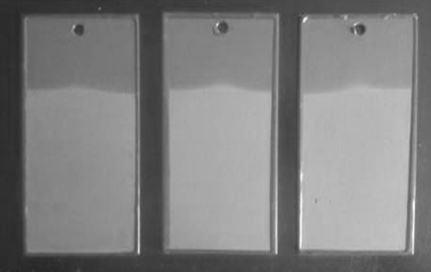

Image

Examples

Embodiment 1

[0025] An anti-corrosion and weather-resistant functional integrated water-based graphene coating is characterized in that it is a two-component coating, including component A and component B, the mass ratio of component A and component B is 4:1, in parts by weight , A component includes 25 parts of water-based epoxy resin, 20 parts of water-based hydroxyl resin, 2 parts of graphene powder material, 13 parts of iron oxide red, 12 parts of mica powder, 5 parts of titanium dioxide, 8 parts of ultraviolet absorber UV- P, 0.5 parts of sodium alkyl naphthalene sulfonate, 1.5 parts of silicone defoamer, 0.5 parts of fumed silica, 0.5 parts of pH regulator, 12 parts of deionized water, component B includes 70 parts of water-based hydroxyl resin curing agent and 30 parts deionized water.

[0026] A preparation method for an anti-corrosion and weather-resistant functional integrated water-based graphene coating, comprising the following steps:

[0027] (1) According to parts by weight...

Embodiment 2

[0034] An integrated water-based graphene coating with anti-corrosion and weather resistance function is characterized in that it is a two-component coating, including component A and component B, and the mass ratio of component A and component B is 5:1. In the coating system, A The components include 30 parts of water-based epoxy resin, 18 parts of water-based hydroxyl resin, 1 part of graphene powder material, 15 parts of iron oxide red, 5 parts of zinc phosphate, 7 parts of titanium dioxide, 8 parts of light stabilizer GW-540, 0.5 Parts of sodium dodecyl sulfonate, 2 parts of water-based mineral oil emulsion, 0.5 parts of fumed silica, 1 part of pH regulator, 12 parts of deionized water, component B includes 80 parts of water-based hydroxyl resin curing agent and 20 parts of deionized water ionized water.

[0035] A preparation method for an anti-corrosion and weather-resistant functional integrated water-based graphene coating, comprising the following steps:

[0036] (1)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com