A kind of chiral MOF material and its preparation method and application

A chiral and dimethyl technology, applied in separation methods, chemical instruments and methods, solid adsorbent liquid separation, etc., can solve single problems and achieve the effect of improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

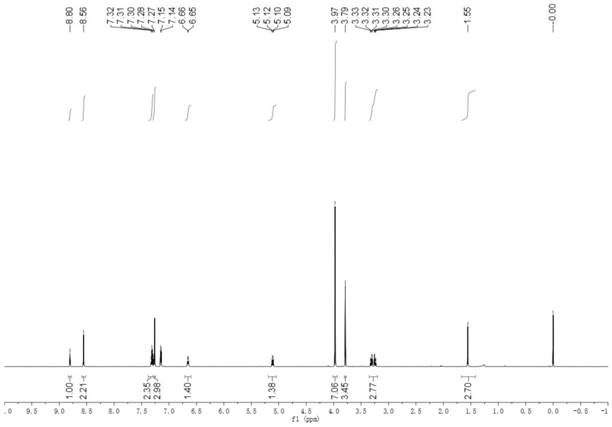

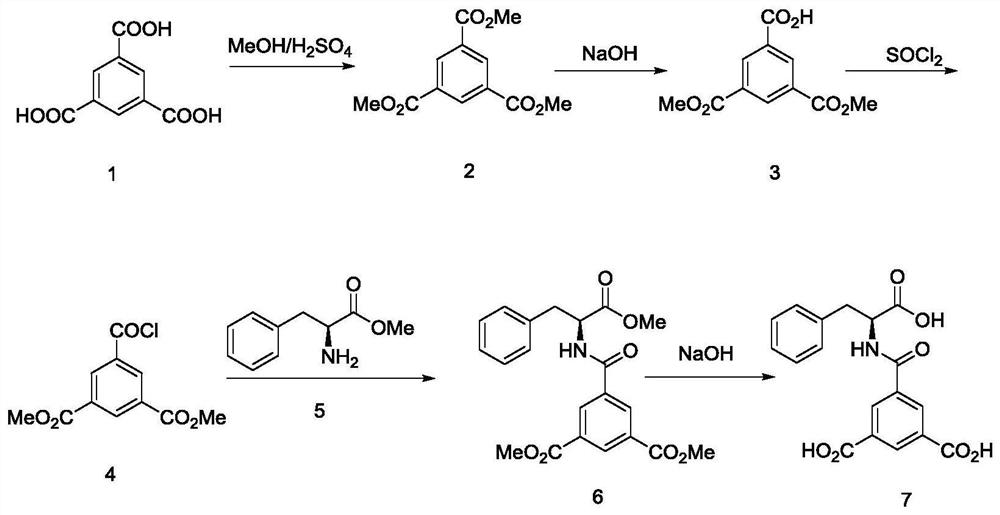

[0024] Such as figure 1 Shown, a kind of preparation method of chiral HPIAMOFs material specifically comprises the following steps:

[0025] (1) Dissolve 4.2 g of m-tribenzoic acid (compound 1) and 1 mL of concentrated sulfuric acid (catalyst) in anhydrous methanol (100 mL), and then reflux at 120° C. for 24 h. After the reaction was completed, most of the solvent was removed, and the resulting residue was slowly added to a saturated sodium bicarbonate solution, then stirred at room temperature for 1 hour, and filtered under reduced pressure to obtain 1,3,5-trimethyl-tribenzoate (compound 2) .

[0026] (2) 3.4g of compound 2 was placed in a 250ml round-bottomed flask, 150ml of methanol was added, 11.7 milliliters of 1mol / L NaOH solution was slowly added into the round-bottomed flask with a constant pressure dropping funnel, and the mixture was vigorously stirred for 24 hours, The solvent was then removed by rotary evaporation. 3.5 g of sodium bicarbonate and 65 ml of water ...

Embodiment 2

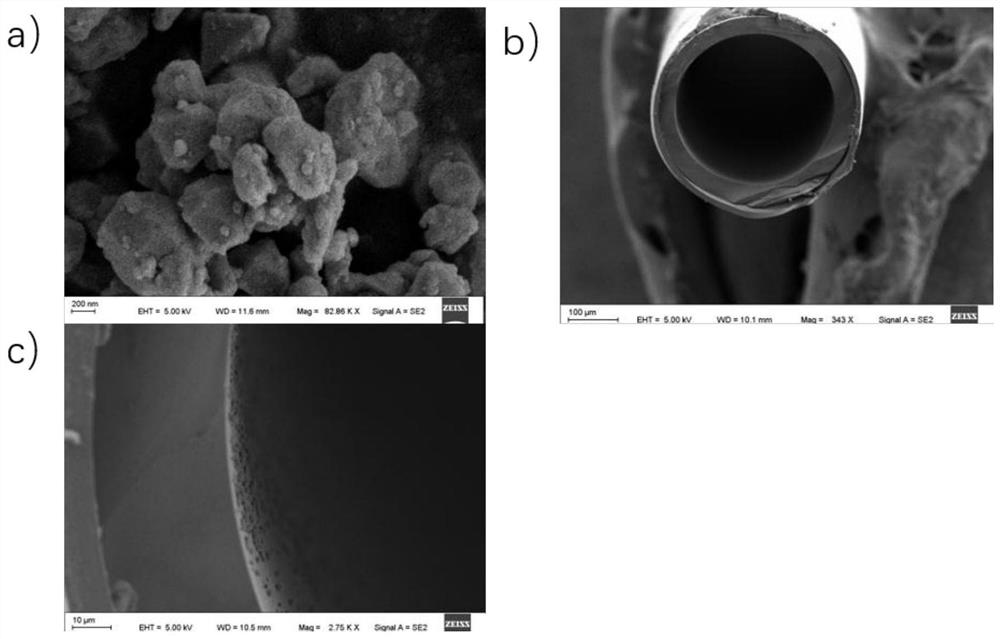

[0032] Prepare 1 ml ethanol suspension of HPIAMOFs (2 mg ml -1 ). First, the HPIAMOFs are filled into the capillary column by a vacuum pump at -0.02MPa to form a plunger about 5 meters long, and then the plunger is pushed at a rate of 0.8-1 meter per minute through the pump regulating valve. After coating, maintain the current condition pressure for 30 minutes. The coated capillary column was transferred to a gas chromatograph for conditioning by passing nitrogen gas through one end. Adjust the nitrogen flow rate to 0.02 MPa, and use the following temperature programming steps: 50 °C for 30 min, 1 °C min -1 to 240°C for 120 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com