Method for preparing 2-(1,3-dioxo-1,3-dihydro-isoindol-2-yl) glutaric acid-5-benzyl ester

A technology of dihydroisoindole and glutaric acid, applied in the preparation of glutamic acid derivatives, the synthesis of N-phthaloylglutamic acid-γ-benzyl ester, compound 2-glutaric acid-5 - In the field of benzyl esters, it can solve the problems of relatively expensive phthalimide, low yield of benzyl glutamate, uneconomical preparation and use, and achieve novel synthetic routes and methods, cheap raw materials, and good chirality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Put L-glutamic acid (14.72g, 0.1mol) in the 500ml flask, phthalic anhydride (14.82g, 0.1mol), toluene (300ml) and triethylamine (7.2ml, 0.05mol), be equipped with reflux separator, Stir and heat to reflux for 7 hours, and after cooling, remove the solvent by rotary evaporation at 50°C, add 1N HCl (40ml) and stir thoroughly, then add dichloromethane (60ml), stir to precipitate a large amount of solid, filter, and wash the filter cake with water and dichloromethane successively. Vacuum drying gave Intermediate 1 as a white solid N-phthaloyl-L-glutamic acid (21.87 g), with a yield of 78.9%.

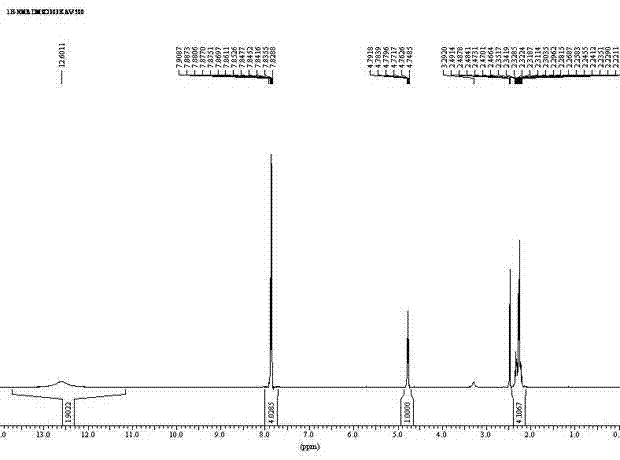

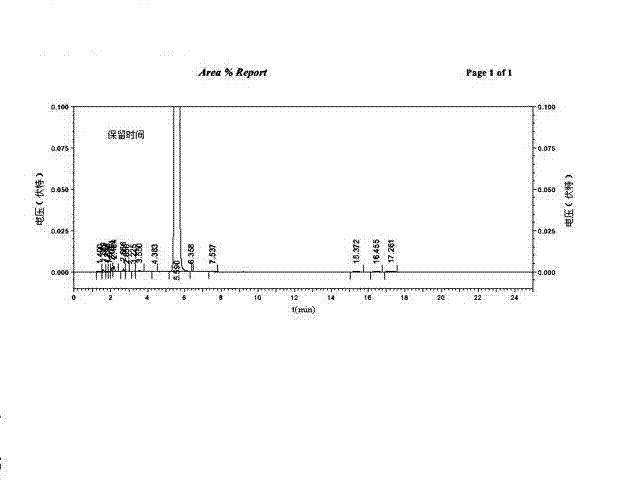

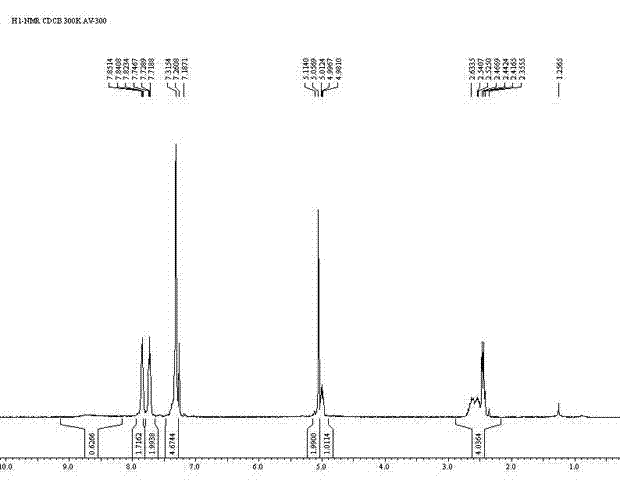

[0037] Intermediate 1 (21.87g, 0.079mol) prepared above was put into a 250ml flask, then added benzyl alcohol (17g, 0.157mol), acetone (50ml) and p-toluenesulfonic acid (2.7g, 0.0157mol), heated to reflux for 3 hour, after cooling, rotary evaporation removed the solvent, added dichloromethane (40ml) and stirred for 2 hours, filtered off the solid, and the solid was washed with dichlor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com