Control method for reducing cut tobacco drying amount and energy consumption in cut tobacco making and drying section

A control method and technology of work section, applied in the fields of tobacco preparation, tobacco, food science, etc., can solve the problem of excessive energy consumption in waiting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

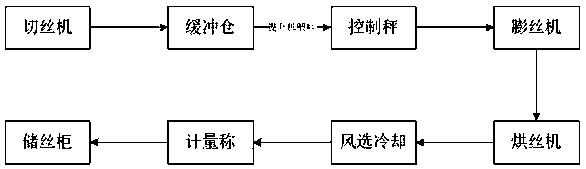

[0022] refer to figure 1 As shown, shredded tobacco is stored in the buffer chamber VM1, passed through the electronic scale DB1, and then transported to the tunnel-type leaf shred moisture regainer HT1 through the vibrating tanks SR1, SR2 and SR3, and then enters the shredded shred drying machine SH1 through the vibrating tank SR4, and the shredded tobacco is dried. After being dried by the machine, the shredded tobacco is transported to winnowing YF1 through the belt FB1, and the winnowing exit passes through the belts FB2 and FB3 to the metering electronic scale RB1, and the exit of RB1 enters the silk distribution cabinet MB1 through the belt FB4.

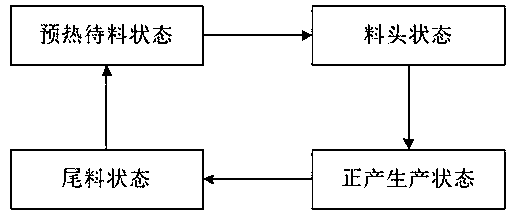

[0023] Operators in general positions will preheat the equipment when the shredder starts to pick up and cut tobacco. When VM1 is filled with about two-thirds of shredded tobacco, it starts to pick up and produce. During this time period, all auxiliary equipment SR1 -3. FB1-4 operates at the preheating frequency speed1; when th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com