Resin lens with high-hardness film structure and preparation method of resin lens

A technology of resin lens and film layer structure, which is applied in the direction of coating, metal material coating process, ion implantation plating, etc., can solve the problems of system hardening, lens becoming brittle and brittle, reducing the impact resistance of the lens, etc., to achieve Improve hardness and impact resistance, improve impact resistance, and improve the effect of dense connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] In a specific embodiment, a method for preparing a resin lens with a high-hardness film layer structure comprises the following steps:

[0031] S1: Make the hardening layer: S11: Dip the ultrasonically cleaned resin lens substrate into the hardening liquid aqueous solution of the type IM9060 with a mass percentage of 25-30%, the immersion temperature is 10-20°C, and the immersion is 5-10 seconds Finally, pull out the solution at a speed of 1.0-3.0mm / s, and dry it at 70-90°C for 2-4 hours, then take out the above-mentioned substrate and send it to a drying oven for drying and curing. The curing temperature is 110-130°C. The curing time is 120 to 240 minutes to obtain a resin lens with a hardened layer; preferably, it is immersed in an IM9060 aqueous solution with a mass percentage of 28.4%; the immersion temperature is 15°C, the time is 5 seconds, and the pulling speed is 2.0mm / s. The drying temperature is 75°C and the drying time is 3 hours; the curing temperature is 1...

Embodiment 1

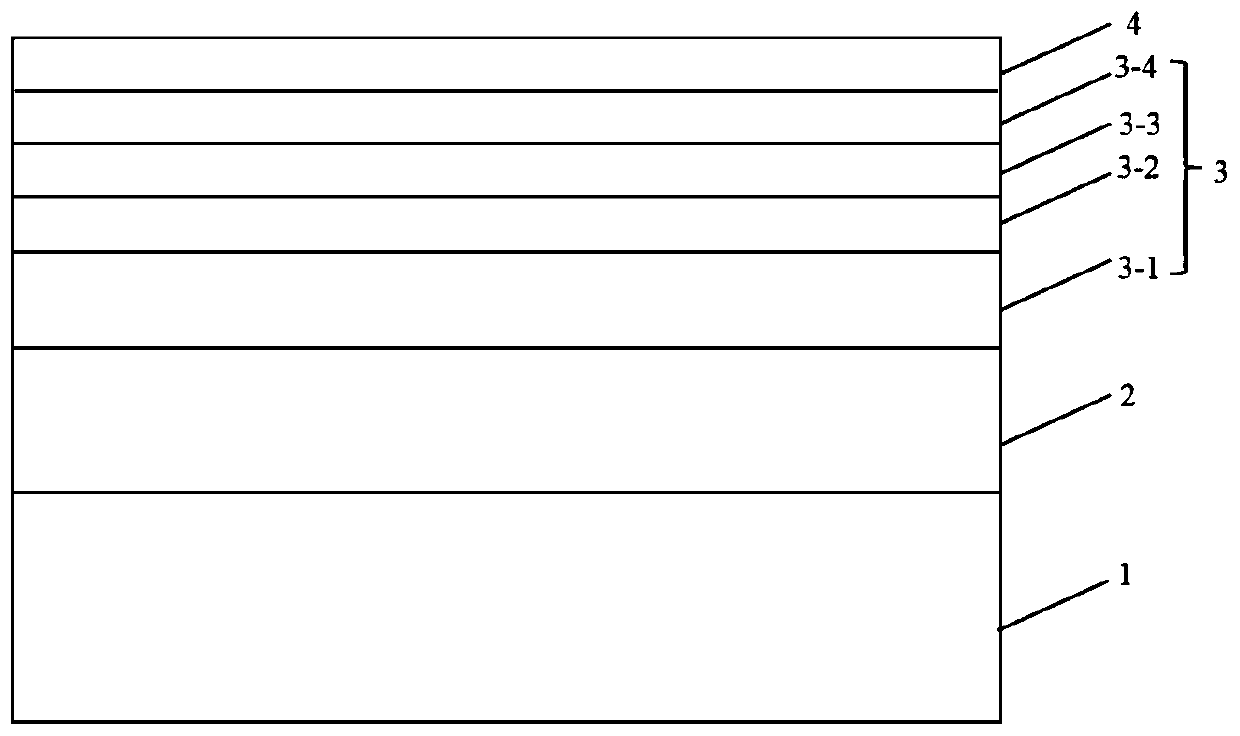

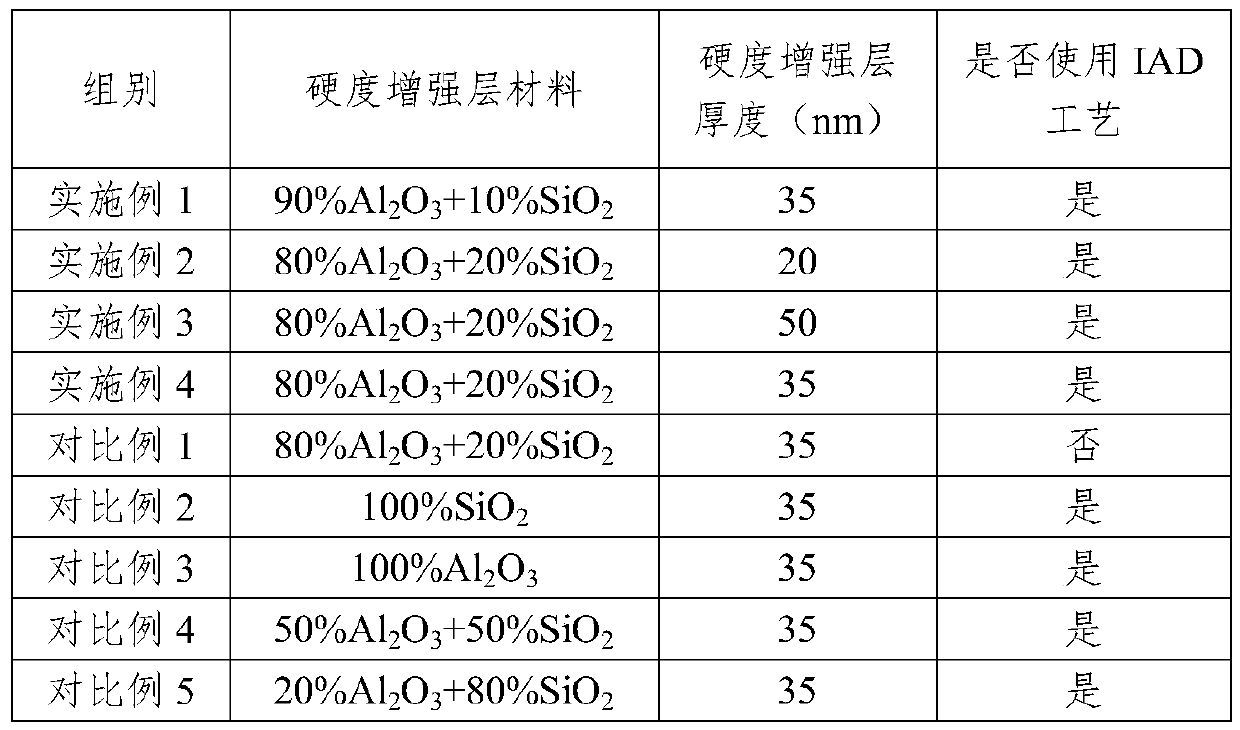

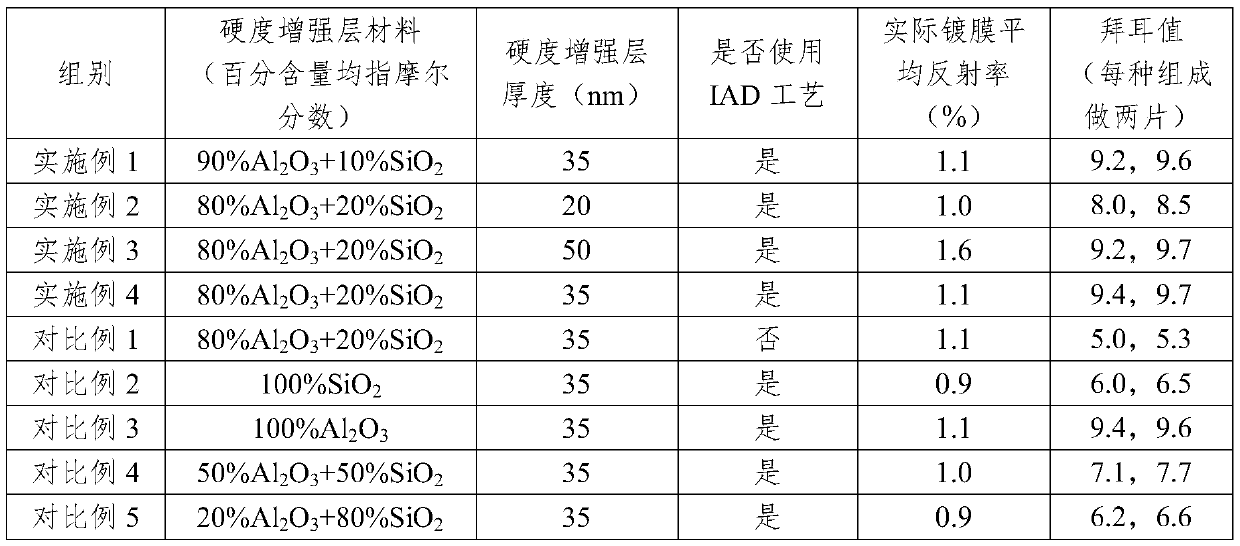

[0040] A resin lens with a high-hardness film layer structure, which includes: a resin lens substrate 1 (purchased from Japan Mitsui Chemicals Co., Ltd. (hereinafter referred to as "Japan Mitsui"), the model is MR8, and its refractive index is 1.6); Hard layer 2 (IM9060, purchased from "SDC"); anti-reflection layer 3 includes: conventional coating layer 3-1 (including: SiO 2 Layer 1 / 122.3nm, ZrO 2 Layer 1 / 24.7nm, SiO 2 Layer 2 / 23nm, ZrO 2 Layer 2 / 68.5nm, ITO layer / 5nm; SiO 2 Base layer 3-2 / 36.9nm; hardness enhancement layer 3-3 (Al 2 o 3 Mole fraction of 90%, SiO 2 Mole fraction of 10%) / 35nm; SiO 2 Protective layer 3-4 / 10nm; waterproof layer 4 (using fluorine-containing waterproof material (such as containing perfluoroalkane (C 12 f 27 N)) / 10nm); The preparation method of the resin lens comprises the following steps:

[0041] S1: Making the hardening layer: S11: Dip the ultrasonically cleaned resin lens substrate into the hardening liquid aqueous solution of the type ...

Embodiment 2

[0050] A resin lens with a high-hardness film layer structure, which includes: a resin lens substrate 1 (purchased from Japan Mitsui Chemicals Co., Ltd. (hereinafter referred to as "Japan Mitsui"), the model is MR8, and its refractive index is 1.6); Hard layer 2 (IM9060, purchased from "SDC"); anti-reflection layer 3 includes: conventional coating layer 3-1 (including: SiO 2 Layer 1 / 139.2nm, ZrO 2 Layer 1 / 27.9nm, SiO 2 Layer 2 / 20.6nm, ZrO 2 Layer 2 / 64.2nm, ITO layer / 5nm; SiO 2 Base layer 3-2 / 53.1nm; hardness enhancement layer 3-3 (Al 2 o 3 Mole fraction of 80%, SiO 2 The mole fraction of 20%) / 20nm; SiO 2 3-4 protective layer / 10nm; waterproof layer 4 (fluorine-containing waterproof material / 10nm); the preparation method of the resin lens is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com