Ground pre-grouting method for small-section high shaft in complex stratum

A complex formation, pre-grouting technology, applied in well sinking, shaft equipment, earth-moving drilling, etc., can solve the problems of difficult seating, risk of water production, and easy to return to the wellbore, so as to reduce the waste of slurry and reduce the difficulty. , Guarantee the effect of grouting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

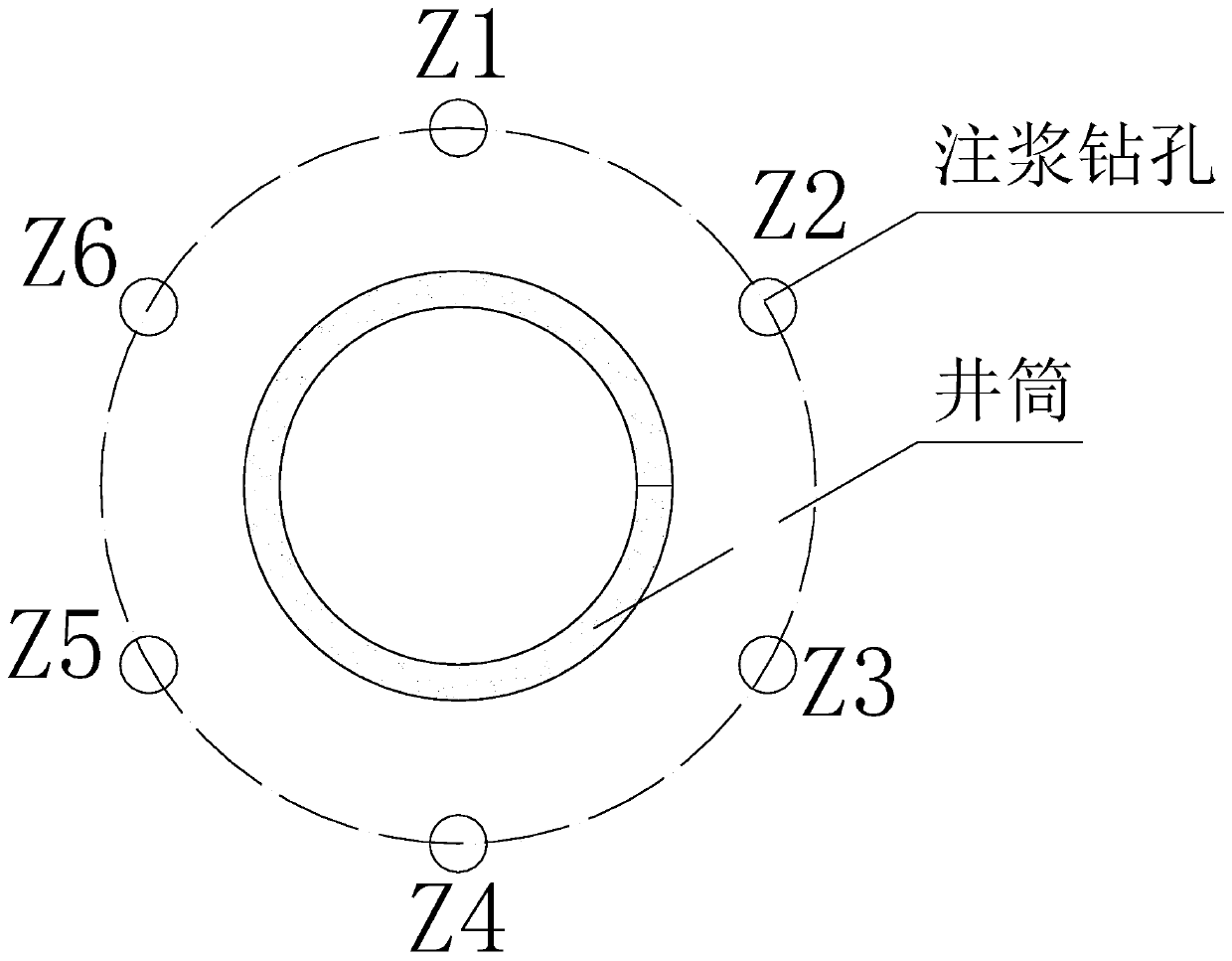

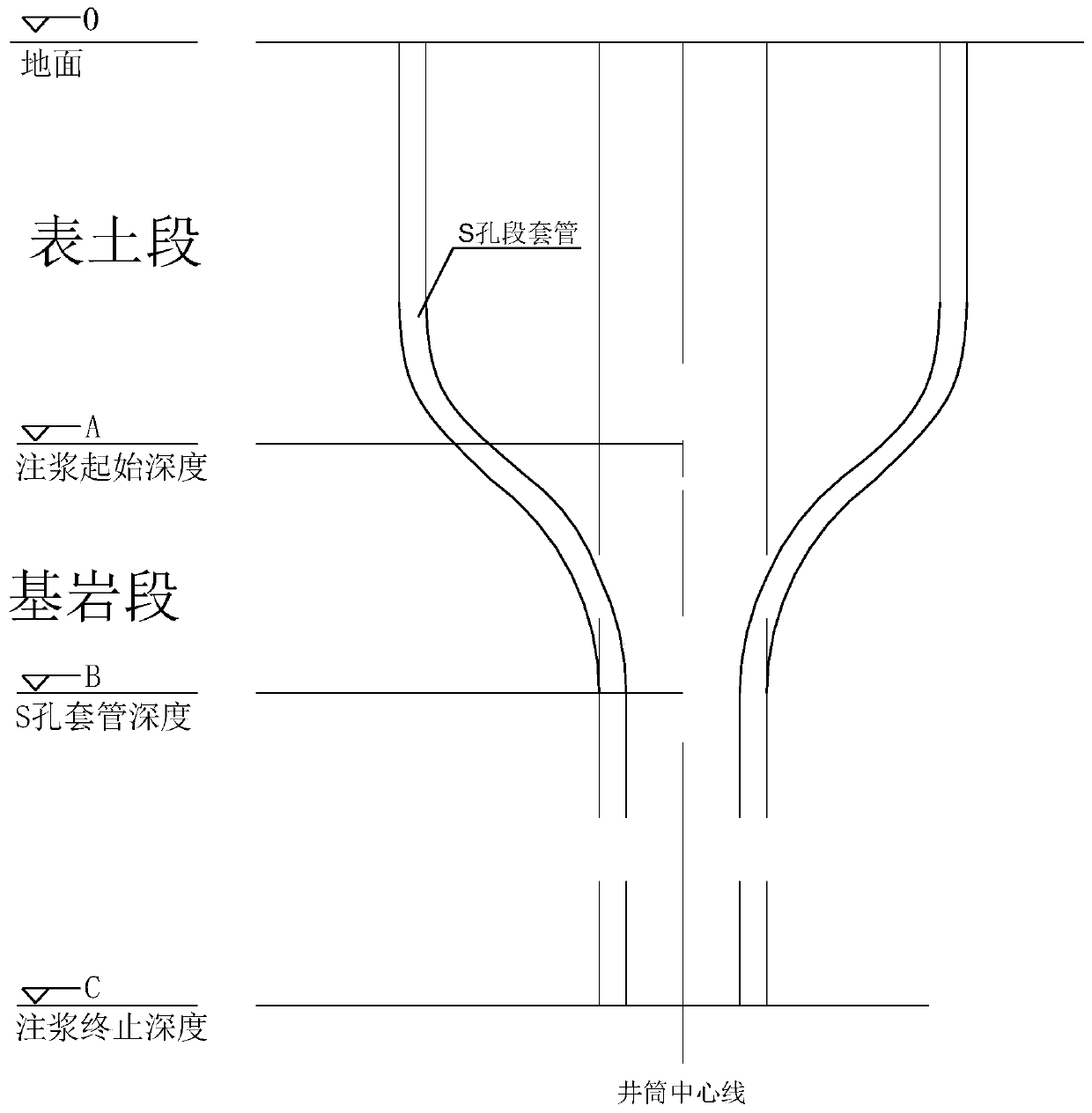

[0060] The ground pre-grouting method for small and high shafts in complex formations in this embodiment includes the following steps:

[0061] (1) Complete the grouting work of surface soil section solid pipe, AB section and CD section according to the method in the prior art, and complete the large section grouting operation of BC section, BC section is the complex stratum of broken zone; A is the grouting starting point B is the starting point of the broken zone, C is the ending point of the broken zone, and D is the ending point of grouting.

[0062] The topsoil section can adopt the full straight grouting drilling method or the S-type grouting drilling method.

[0063] This embodiment adopts the full straight grouting drilling method, A is the starting point of grouting, B is the starting point of the broken zone, C is the ending point of the broken zone, and D is the ending point of grouting. The height from the ground to the grouting starting point A is the surface soi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com