A Construction Method of Stable Roof-Coal Pillar Structure in Fully Mechanized Caving Gob-side Coal Roadway

A construction method and empty coal technology, which is applied in the fields of earth cube drilling, surface mining, mining equipment, etc., can solve obstacles to resource-saving and high-yield and high-efficiency fully mechanized caving mining, poor timing of cracked and thick top coal, and overlying rock To solve problems such as structural instability, achieve directional and efficient fracturing, avoid gas disaster accidents, and achieve superior fracturing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

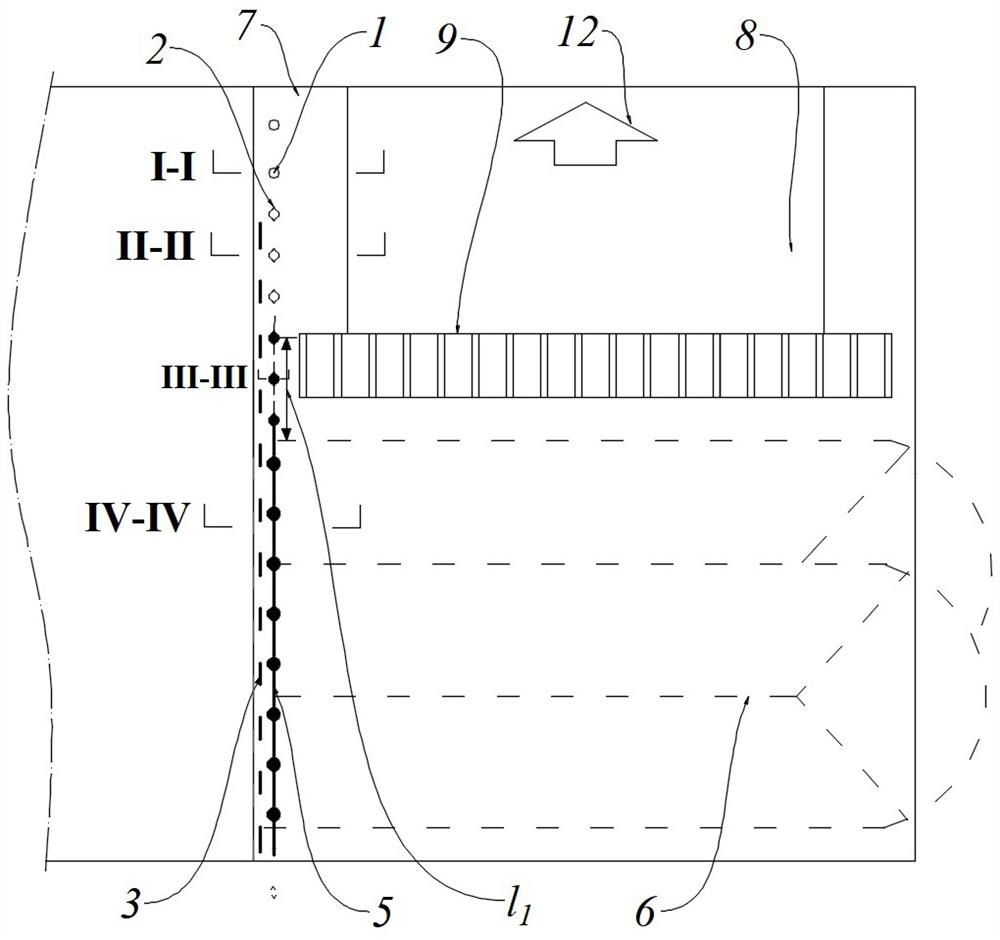

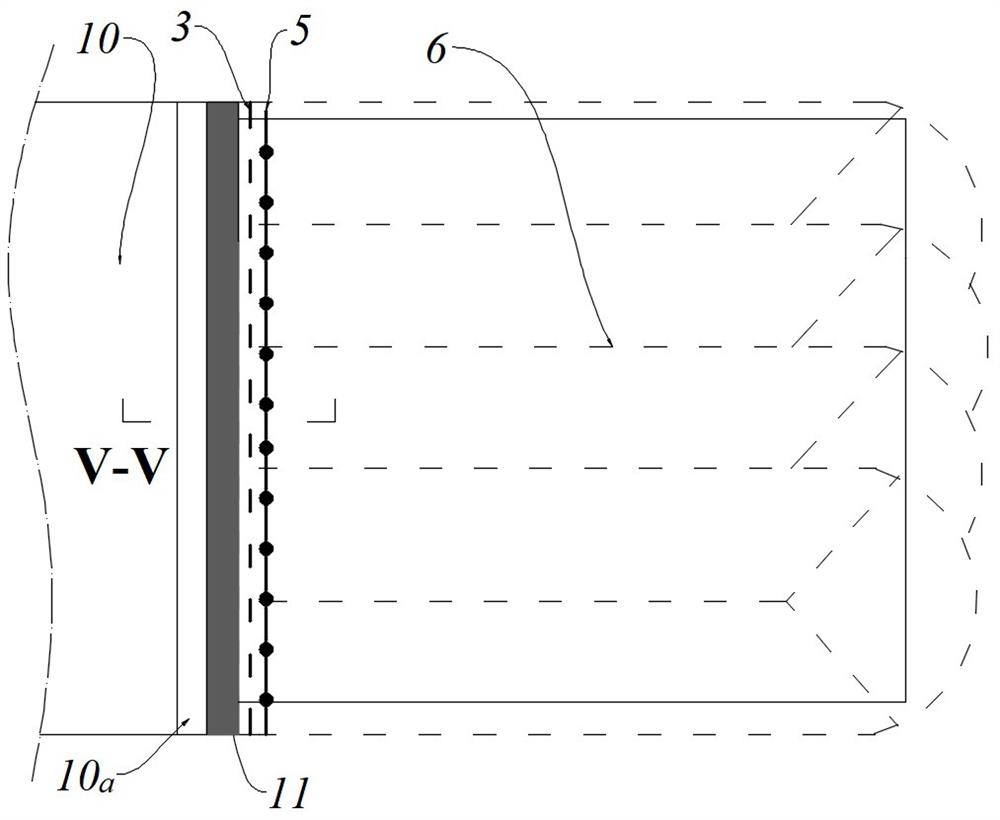

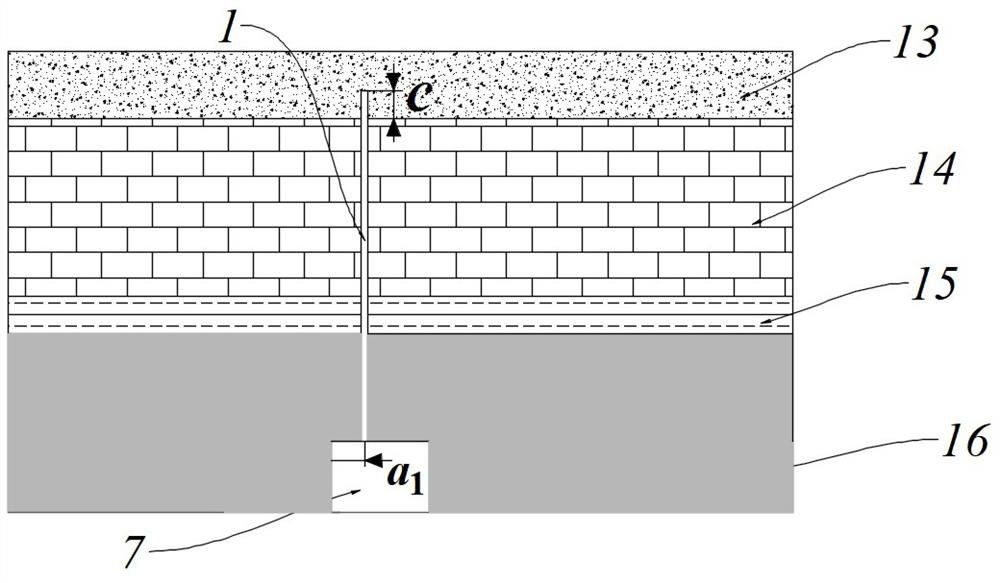

[0067]The thickness of a mining coal seam is 9m, the roof is basically thick and hard, and fully mechanized caving mining is adopted. The method for constructing a stable roof-coal pillar structure along a fully mechanized caving coal roadway of the present invention is as follows:Figure 1-15As shown, the stable and reliable coal roadway along the goaf is realized, and the final working face is safe.

[0068]The specific implementation methods and steps are:

[0069]Step 1: Such asfigure 1 ,3As shown, the expansion fracturing borehole 1 is arranged in the mining roadway 7 of the advanced fully mechanized caving mining face 8, and the distance between the expansion borehole and the non-mining side coal bodya1Is 20cm, and the distance between expansion fracturing drill hole 1 isb, The fracturing range of expansion fracturing drill hole 1 is the entire basic roof 14;

[0070]Step 2: Such asfigure 1 As shown, micro-slits 2 are cut on both sides of the expansion fracturing drill hole 1, and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com