Anti-frost heaving and anti-seismic composite foundation structure

A composite foundation, anti-frost heave technology, applied in the field of foundation anti-freeze and earthquake resistance, can solve the problems of economic loss and safety hazards, accelerated building collapse, high earthquake disaster intensity, etc. The effect of preventing and controlling frost heave deformation and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

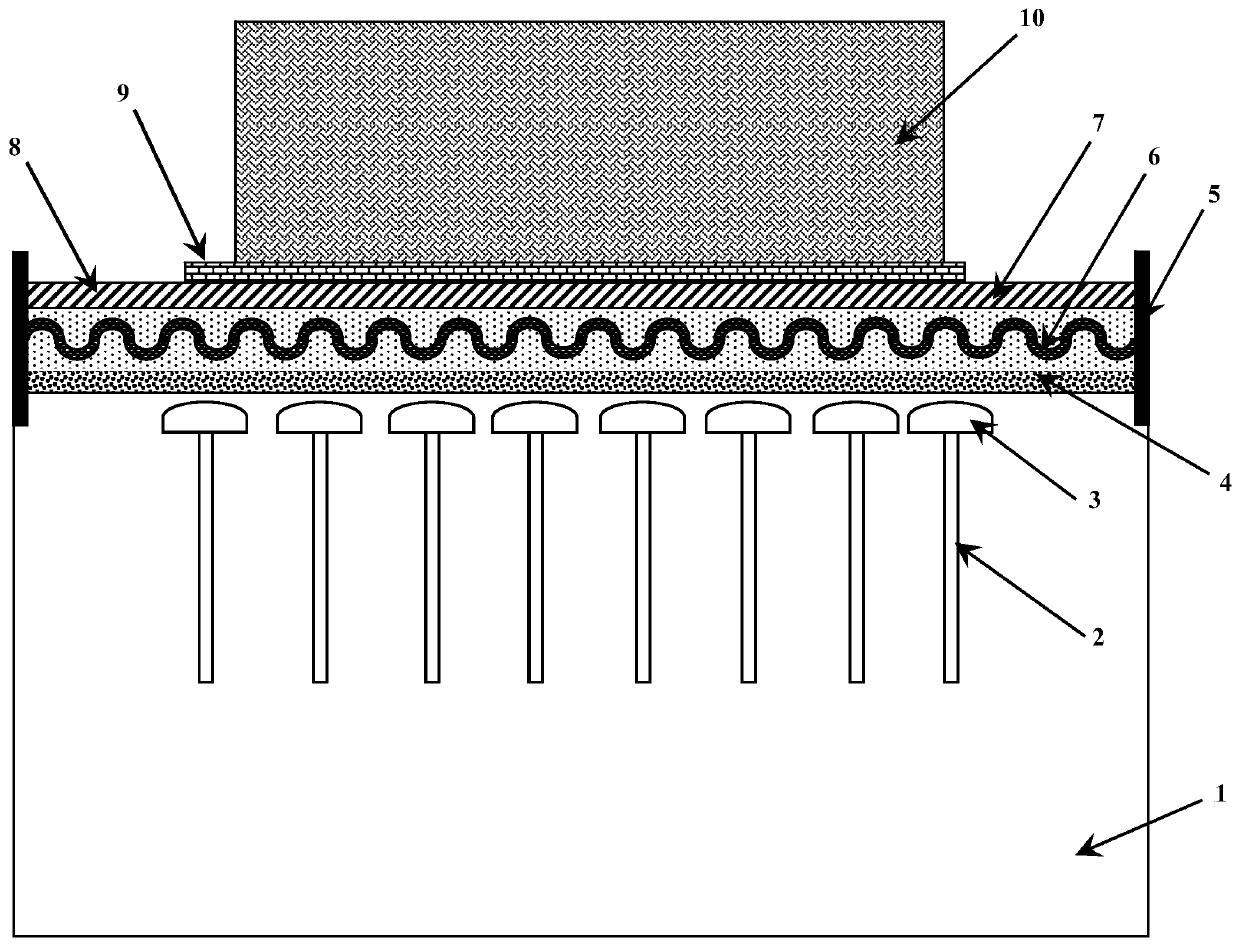

[0021] Such as figure 1 As shown, a frost heaving and anti-seismic composite foundation structure, including a plurality of rigid cap piles, coarse sand cushion, rubber gravel reinforced cushion, rubber shock-isolation cushion and raft, is uniformly arranged in the foundation soil with multiple A rigid hat-type pile, the coarse sand cushion is located on the top of the foundation soil, the rubber gravel reinforced cushion is located on the above the coarse sand cushion, and the rubber shock-absorbing cushion is located on the above the rubber gravel reinforced cushion The raft is located above the rubber shock-absorbing cushion, the coarse sand cushion, the rubber gravel reinforced cushion and the rubber shock-isolation cushion are provided with baffles, and the building is built on the raft. The rigid cap pile includes a pile cap and a pile body, the upper end of the pile body is hingedly connected with the pile cap, and the lower end of the pile body is located in the bearin...

Embodiment 2

[0024] The construction method of a kind of anti-frost heaving and anti-seismic composite foundation structure described in embodiment 1, the steps are as follows:

[0025] Step 1, prefabricated pile body and pile cap, raft, baffle;

[0026] Step 2, drive the prefabricated pile body into the foundation soil, the lower end of the pile body is in the bearing layer, and the upper end of the pile body is hinged with the mushroom-shaped pile cap, and a plurality of rigid hat-type piles are symmetrically arranged according to the center;

[0027] Step 3: Arrange a circle of prefabricated baffles around the surrounding area. The baffles are buried in the soil at a depth of 20-40mm and are 20-40mm higher than the top of the cushion;

[0028] Step 4, laying a layer of coarse sand cushion with a thickness of 1-1.5m.

[0029] Step 5: Mix rubber and pebbles or crushed stones evenly at a ratio of 1-2:2, lay a 1 / 2 thickness rubber gravel cushion, lay a wave-shaped geogrid, and then lay a 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com