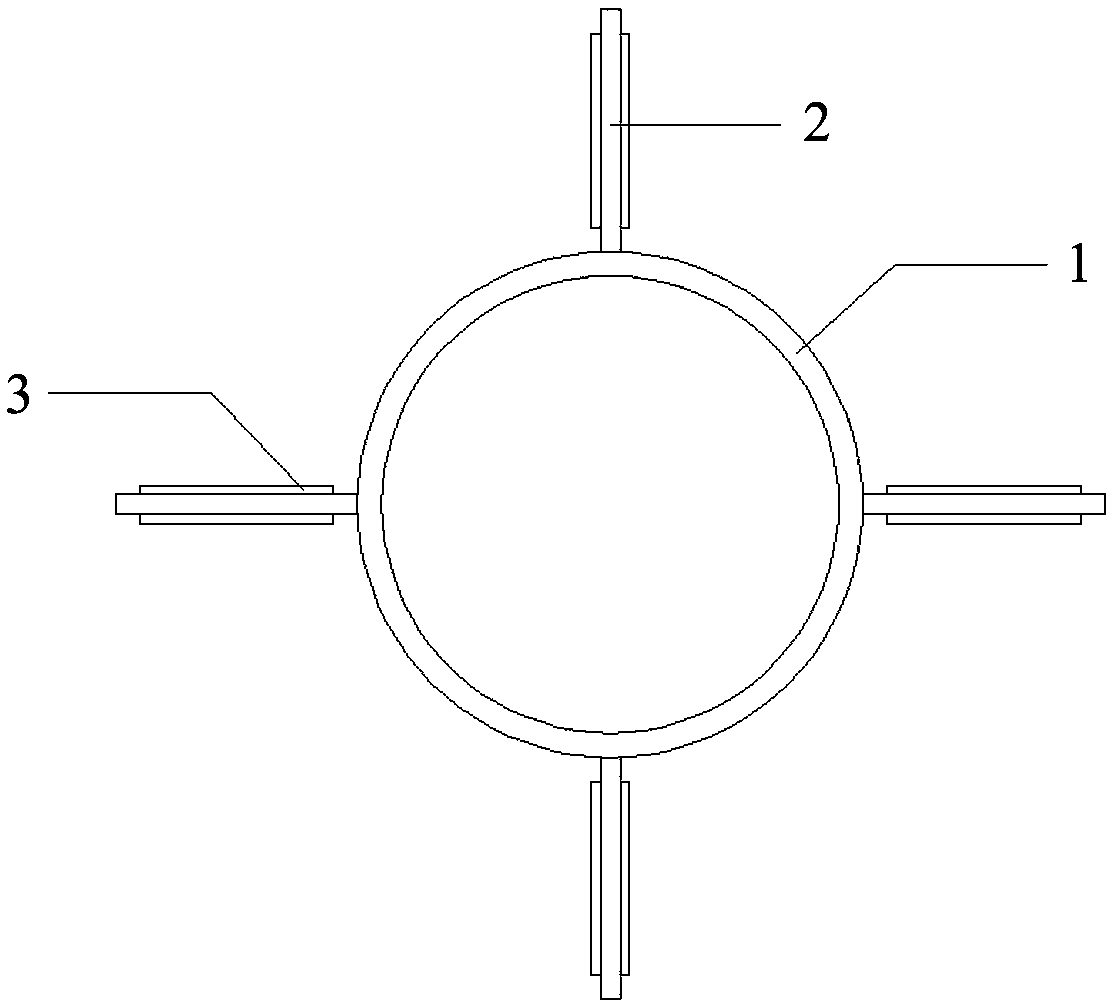

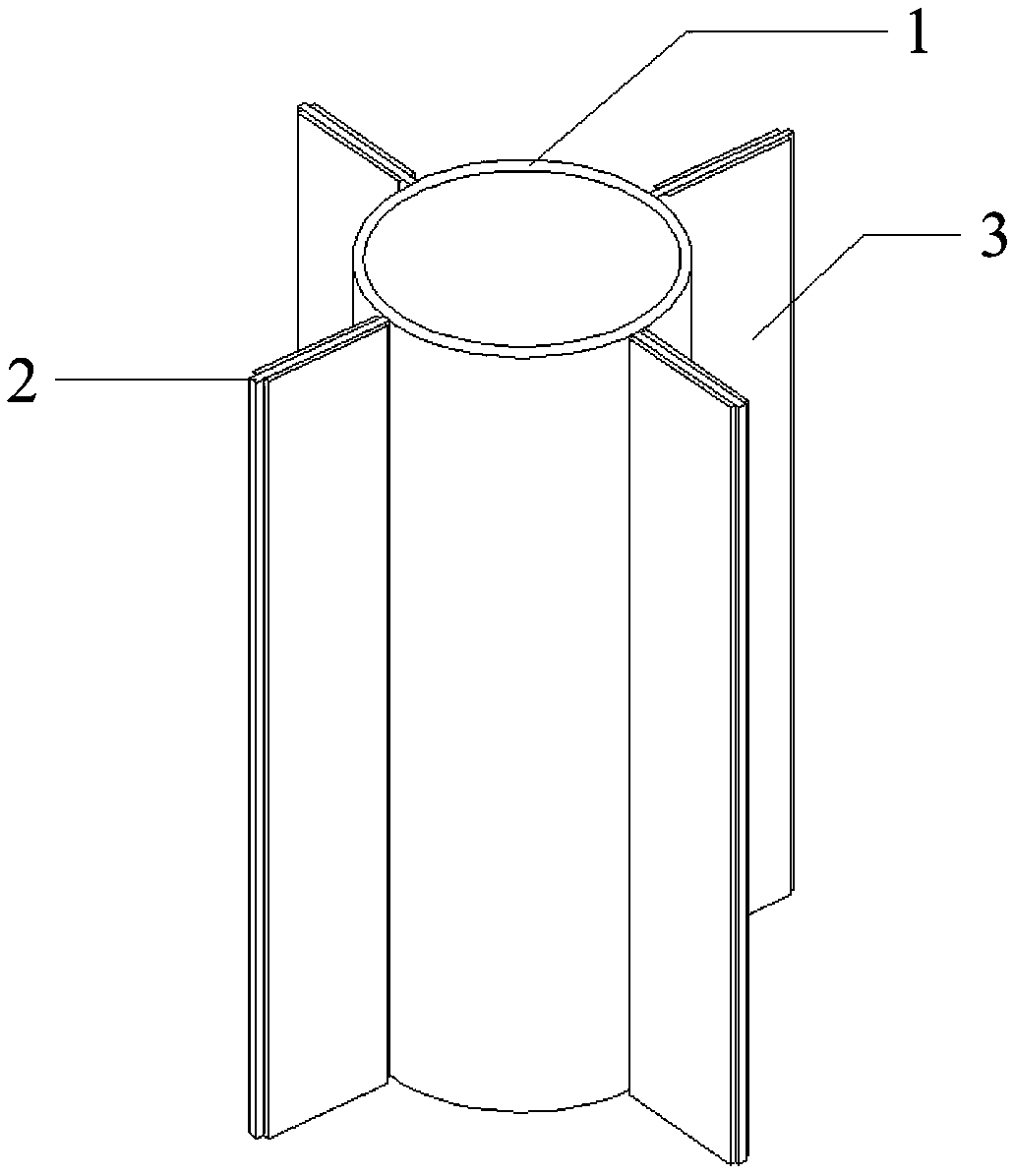

Cross-shaped steel pipe combined pile with dual functions of bearing and draining

A dual-function, combined pile technology, used in sheet pile walls, soil protection, construction, etc., can solve the problems of not being able to be used as a vertical drainage channel, soft clay can not be used for drainage and consolidation, etc. The effect of drainage capacity, reduction of construction steps, and increase of stressed area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Silt foundation with standard penetration number N=0-1.

[0017] The diameter of the main steel pipe of the cross-shaped steel pipe composite pile is 2.0m, the wall thickness of the steel pipe pile is 25mm, the width of the steel support plate is 2.0m, the wall thickness of the steel support plate is 20mm, and the width of the plastic drainage composite material is 1.8m. 20×10 -3 cm / s, and the pile spacing of cross-shaped steel pipe composite piles is 8.0m.

[0018] The 30m-long cross-shaped steel pipe composite pile with dual functions of bearing and drainage is installed by a piling ship. The 125-type piling hammer is used. The maximum stroke of the hammering part is 2100mm, and the hammering frequency is 45-50 times / min until the cross-shaped steel pipe combination The piles go into the designated position, and the installation is finally completed.

Embodiment 2

[0020] Soft soil foundation with standard penetration number N=2-5.

[0021] The diameter of the main steel pipe of the cross-shaped steel pipe composite pile is 1.0m, the wall thickness of the steel pipe pile is 20mm, the width of the steel support plate is 2.0m, the wall thickness of the steel support plate is 15mm, and the width of the plastic drainage composite material is 0.8m. 10×10 -3 cm / s, and the pile spacing of cross-shaped steel pipe composite piles is 4.0m.

[0022] The 30m-long cross-shaped steel pipe composite pile with dual functions of bearing and drainage is installed by a piling ship. The 125-type piling hammer is used. The maximum stroke of the hammering part is 2500mm, and the hammering frequency is 40-45 times / min until the cross-shaped steel pipe combination The piles go into the designated position, and the installation is finally completed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com