Preparation method of surface function synchronous modified flexible nanofiber composite membrane

A nanofiber and modification technology, which is applied in the field of preparation of flexible nanofiber composite membranes with synchronous modification of surface functions, can solve the problems of poor adhesion of functional materials and poor uniformity of film formation, so as to improve application performance, increase loading rate, and increase ratio Effect of Capacitance Characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Prepare a mixed solution of graphene and polymer

[0037] Dissolving the graphene powder and polymer powder PVDF in an organic solvent, fully stirring, and fully shaking in an ultrasonic oscillator, so that the graphene particles are evenly dispersed in the mixed solution, and an electrospinning inner shaft solution is obtained.

[0038] (2) Preparation of graphene suspension

[0039] The graphene powder is dissolved in an organic solvent, fully stirred and oscillated to obtain a uniformly mixed graphene suspension.

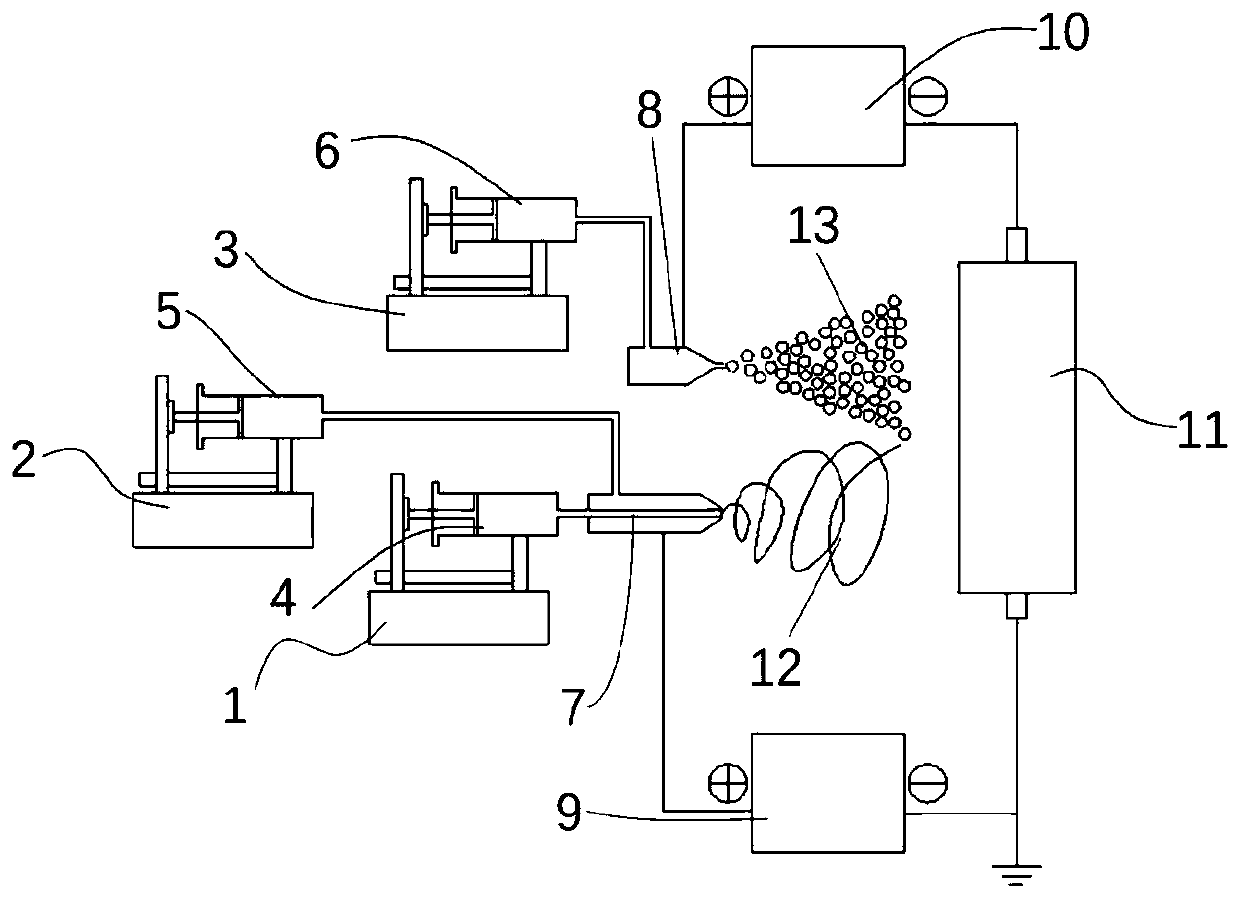

[0040] (3) Synchronous modification process to prepare composite fiber membrane

[0041] Fill the mixed reagent of high molecular polymer and graphene prepared in the step (1) in the first injection needle tube 4, make the reagent pass into the inner shaft channel of the coaxial spinning needle 7 by the first syringe pump 1, the step The graphene suspension prepared in (2) is filled in the second injection needle tube 5, and the reagent is passed int...

Embodiment 2

[0046] (1) Prepare a mixed solution of graphene and polymer

[0047] Dissolving the graphene powder and polymer powder PVDF in an organic solvent, fully stirring, and fully shaking in an ultrasonic oscillator, so that the graphene particles are evenly dispersed in the mixed solution, and an electrospinning inner shaft solution is obtained.

[0048] (2) Preparation of graphene suspension

[0049] The graphene powder is dissolved in an organic solvent, fully stirred and oscillated to obtain a uniformly mixed graphene suspension.

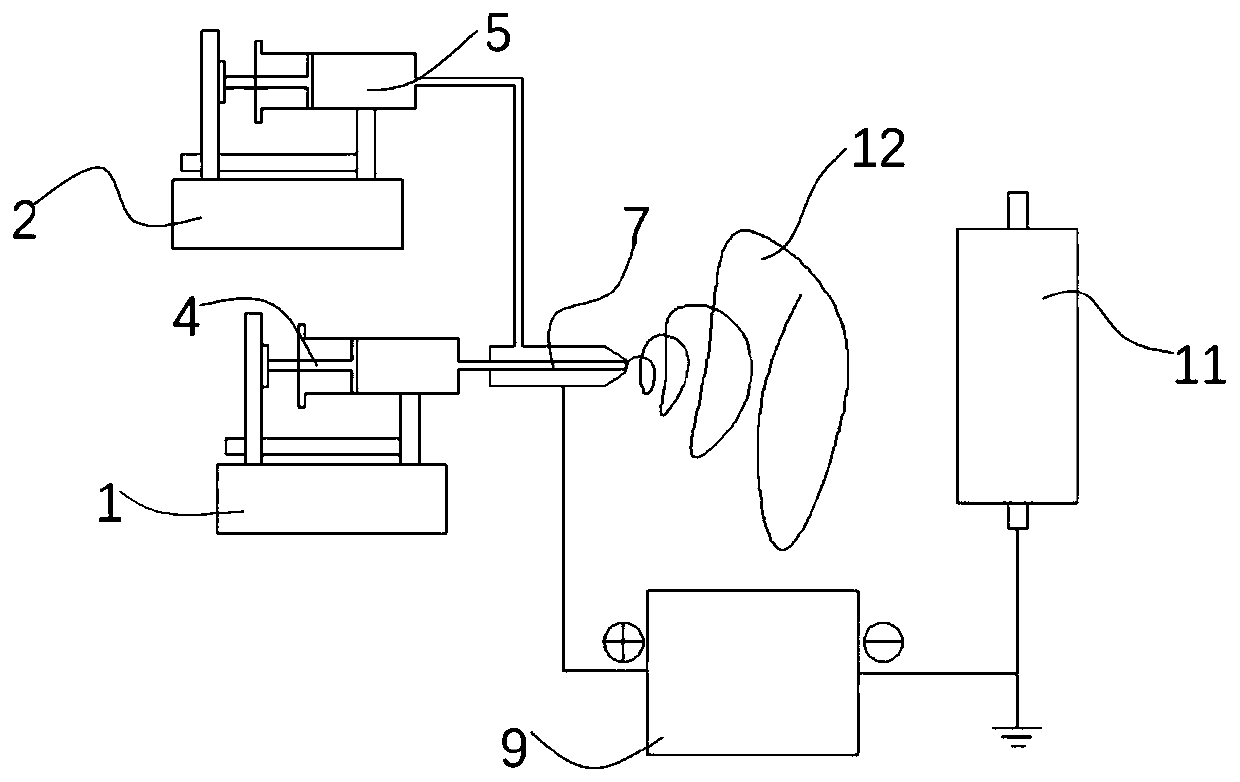

[0050] (3) Preparation of composite fiber membrane by coaxial spinning process

[0051] Fill the mixed reagent of high molecular polymer and graphene prepared in the step (1) in the first injection needle tube 4, make the reagent pass into the inner shaft channel of the coaxial spinning needle 7 by the first syringe pump 1, the step The graphene suspension prepared in (2) is filled in the second injection needle tube 5, and the reagent is passed into...

Embodiment 3

[0055] (1) Prepare a mixed solution of graphene and polymer

[0056] The polymer powder PVDF is dissolved in an organic solvent, and the electrospinning solution is obtained after fully stirring.

[0057] (2) Preparation of graphene suspension

[0058] The graphene powder is dissolved in an organic solvent, fully stirred and oscillated to obtain a uniformly mixed graphene suspension.

[0059] (3) Preparation of polymer fiber membrane

[0060] The electrospinning solution prepared in step (1) is used to prepare a polymer fiber membrane through an electrospinning process.

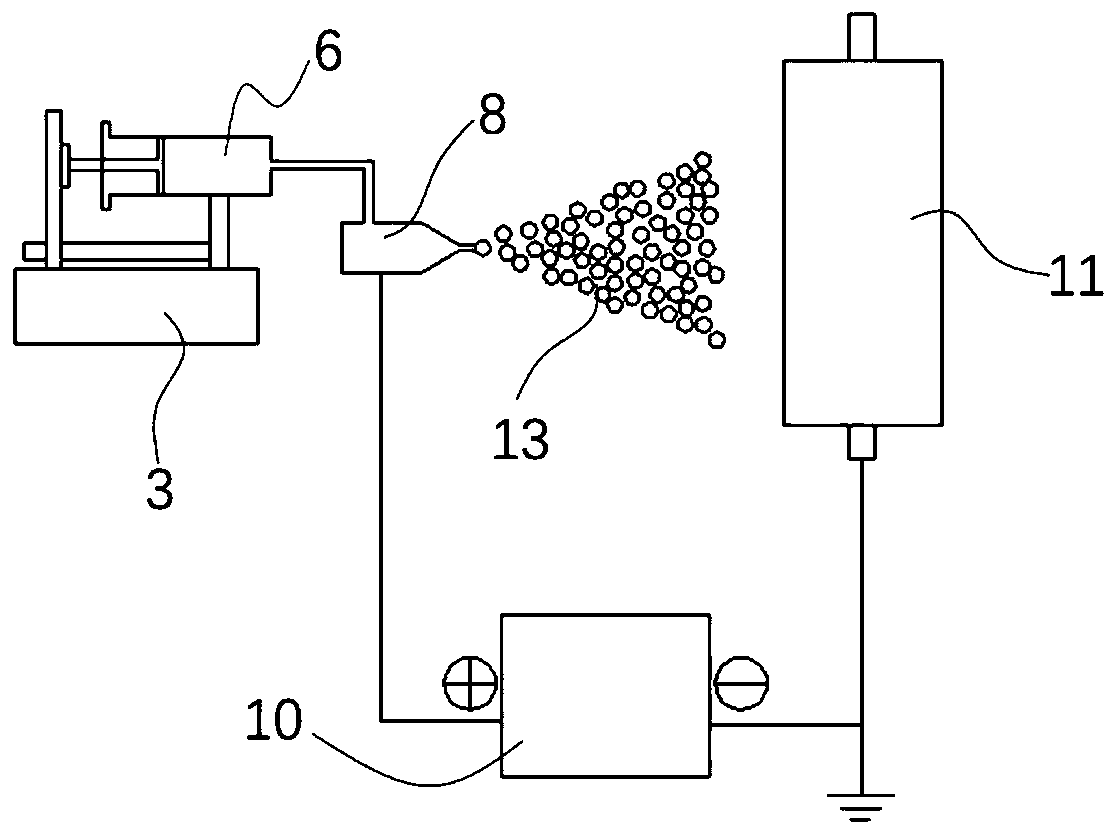

[0061] (4) Preparation of composite fiber membrane by electrostatic atomization modification

[0062] The PVDF fiber film that step (3) is obtained is placed on collecting cylinder 11, the graphene suspension prepared in step (2) is passed in the atomizing nozzle 8 by the 3rd injection needle tube 6, by the 3rd injection pump 3 Control the atomization speed, use the second high-voltage power supply 10 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com