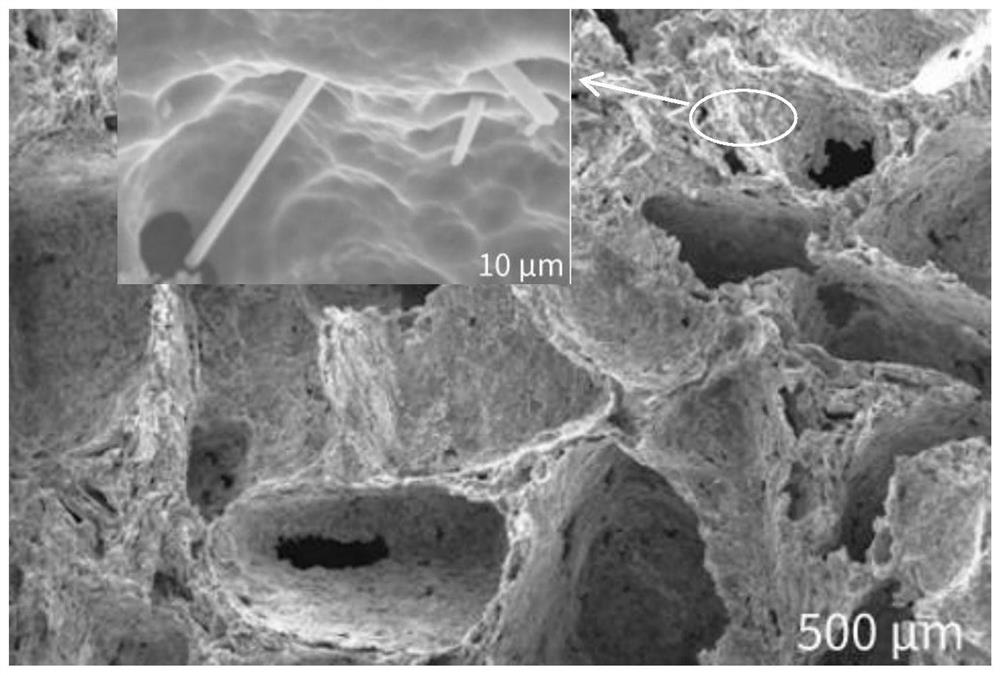

Microcellular foamed high-strength anti-aging ppa/petg composite plastic manhole cover and preparation method thereof

A technology of microcellular foaming and composite plastics, which is applied in the field of composite plastic manhole covers and their preparation, can solve problems such as short durability, difficult processing, and insufficient load-bearing capacity, so as to overcome the reduction of strength, improve anti-aging performance, and enhance the effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] A microcellular foamed high-strength anti-aging PPA / PETG composite plastic well cover is composed of the following components in mass percentage:

[0083] PPA resin: 70 parts

[0084] PETG resin: 30 parts

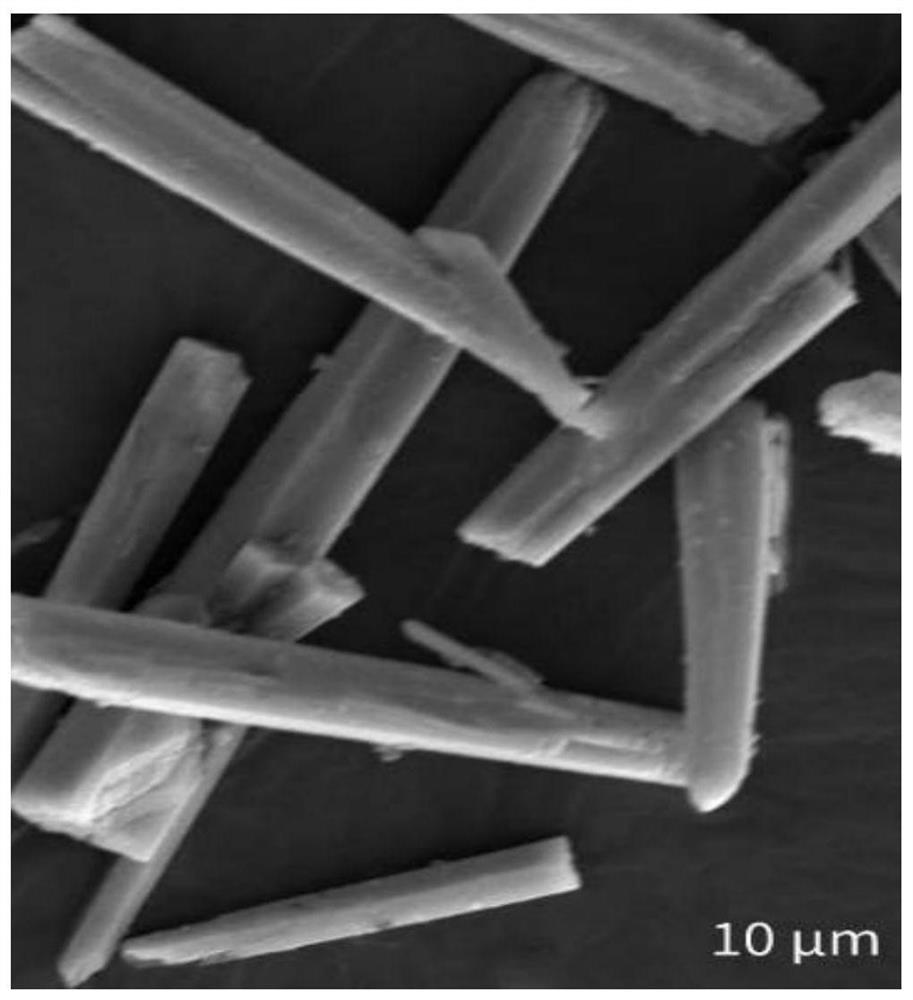

[0085] Anti-aging compound foaming agent: 8 parts

[0086] Reinforcement material: 20 servings

[0087] Compatibilizer: 6 servings

[0088] Toughening agent: 15 parts

[0089] Lubricant: 2 parts

[0090] Antioxidant: 0.5 part.

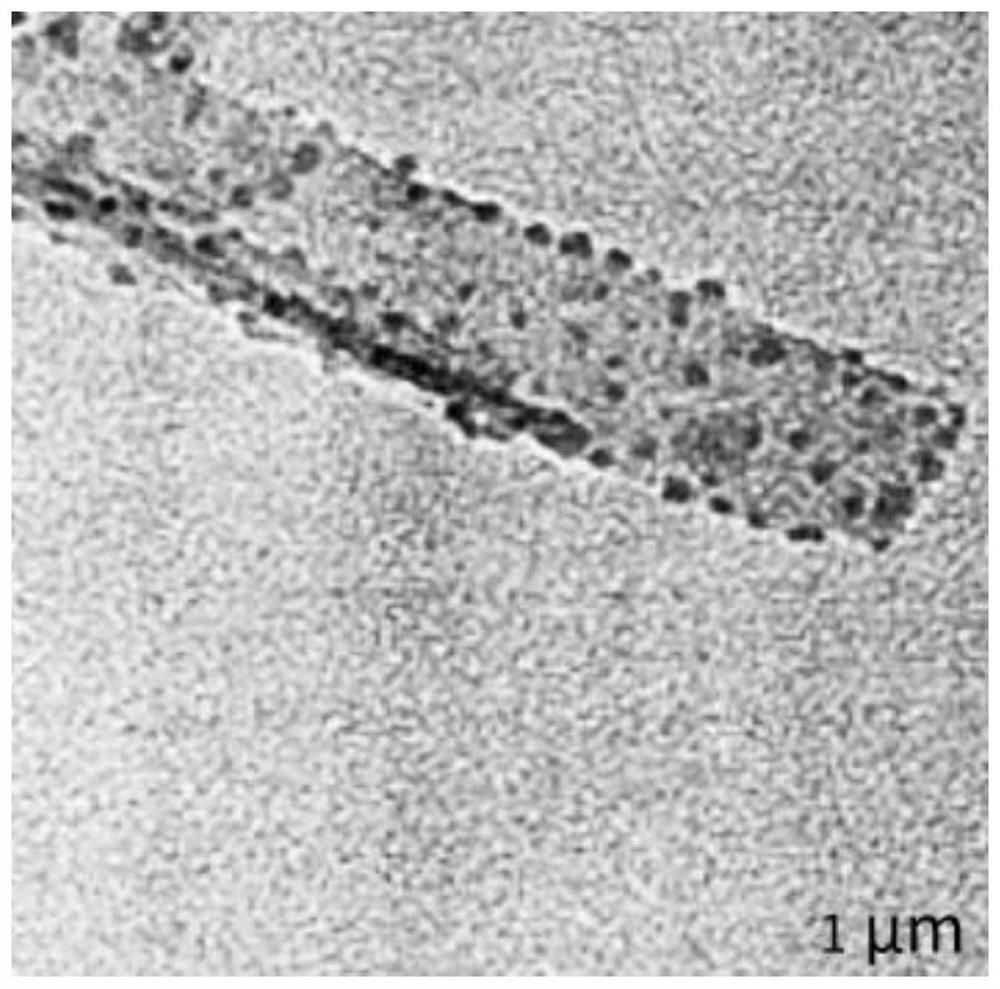

[0091] The anti-aging composite foaming agent is embedded surface-loaded TiO 2 Halloysite nanotubes;

[0092] The embedded surface supported TiO 2 Halloysite nanotube anti-aging composite foaming agent is prepared by the following method:

[0093] Step A: Halloysite Nanotubes and TiO 2 the drying process

[0094] Weigh out 5g of TiO 2 and 2 g of halloysite nanotubes were placed in a vacuum drying oven, and dried at a constant temperature of 80 °C for 2 d to obtain dry halloysite nanotubes and TiO 2 ,spare;

[0095] Dried halloys...

Embodiment 2

[0116] A microcellular foamed high-strength anti-aging PPA / PETG composite plastic well cover, comprising the following components in mass percentage:

[0117] PPA resin: 70 parts

[0118] PETG resin: 30 parts

[0119] Anti-aging compound foaming agent: 8 parts

[0120] Reinforcement material: 20 servings

[0121] Compatibilizer: 6 servings

[0122] Toughening agent: 15 parts

[0123] Lubricant: 2 parts

[0124] Antioxidant: 0.5 part.

[0125] The anti-aging composite foaming agent is embedded surface-loaded TiO 2 Halloysite nanotubes;

[0126] The embedded surface supported TiO 2 Halloysite nanotube anti-aging composite foaming agent is prepared by the following method:

[0127] Step A: Halloysite Nanotubes and TiO 2 the drying process

[0128] Weigh 7g of TiO 2 and 3 g of halloysite nanotubes were placed in a vacuum drying oven, and dried at a constant temperature of 90 °C for 3 days to obtain dry halloysite nanotubes and TiO 2 ,spare;

[0129] Dried halloysite ...

Embodiment 3

[0153] A microcellular foamed high-strength anti-aging PPA / PETG composite plastic well cover is composed of the following components in mass percentage:

[0154] PPA resin: 70 parts

[0155] PETG resin: 30 parts

[0156] Anti-aging compound foaming agent: 8 parts

[0157] Reinforcement material: 20 servings

[0158] Compatibilizer: 6 servings

[0159]Toughening agent: 15 parts

[0160] Lubricant: 2 parts

[0161] Antioxidant: 0.5 part.

[0162] The anti-aging composite foaming agent is embedded surface-loaded TiO 2 Halloysite nanotubes;

[0163] The embedded surface supported TiO 2 Halloysite nanotube anti-aging composite foaming agent is prepared by the following method:

[0164] Step A: Halloysite Nanotubes and TiO 2 the drying process

[0165] Weigh 8g of TiO 2 and 4 g of halloysite nanotubes were placed in a vacuum drying oven, and dried at a constant temperature of 95 °C for 2d to obtain dry halloysite nanotubes and TiO 2 ,spare;

[0166] The dried halloysit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com