A kind of preparation method and application of zirconia porous ceramic material

A technology of porous ceramics and zirconia, applied in the field of preparation of zirconia porous ceramics, can solve the problems of difficult preparation of high-porosity materials, difficulty in reducing gas heat conduction, uneven distribution, etc., and achieve high strength and low thermal conductivity Efficiency, improve the effect of heat insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

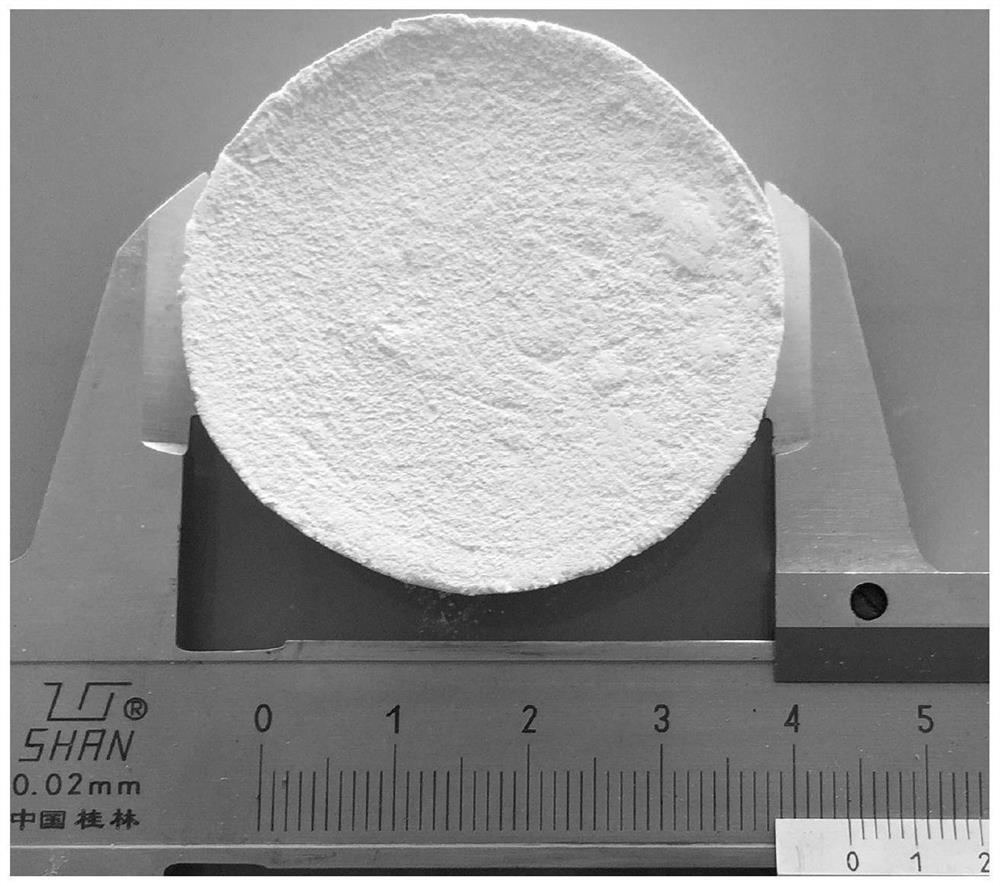

Embodiment 1

[0028] Among the raw materials used in the examples, the particle size of the 8YSZ powder is 40-50 nm, and the crystal phase is a fully stable cubic phase. Adopt the ZrO of smaller particle size in the embodiment 2 ZrO with smaller pore size can be obtained 2 Porous ceramics, and will not be affected by ZrO at high temperature 2 The phase change produces a volume change, leading to cracking. Gas phase SiO as additive 2 The particle size of ZrO is 7-40nm, and the particle size of agglomerated particles is 200-400nm; ZrO 2The particle size of the hollow sphere is 2-5μm, and the wall thickness is 200-400nm; the diameter of the 8YSZ short fiber is 5-10μm, and the length is 2-5mm.

[0029] Mix 13g of N-methylolacrylamide (N-MAM), 1.3g of N,N-methylenebisacrylamide (MBAM) and 110g of tert-butanol (TBA) to form a 11.5wt% premix, Then add 0.38g N,N,N',N'-tetramethylethylenediamine (TEMED), 50g 8YSZ nanopowder, 3g TiO 2 Powder, 0.1g of ammonium polyacrylate and 1.3g of PVP were p...

Embodiment 2

[0032] Mix 13.5g N-MAM, 1.35g MBAM, 100g TBA and 15g absolute ethanol to form a premix with a mass fraction of 11.4wt%, then add 0.38g TEMED, 60g 8YSZ nanopowder, 3.3g SiC powder, 0.2g sodium hexametaphosphate and 1.35g PVP were ball milled for 1 hour, then 6g of 8YSZ fiber was added, stirred for 5 minutes, and then ultrasonically vibrated for 5 minutes to obtain a stable ceramic suspension slurry. Follow-up steps are carried out according to embodiment 1, obtain ZrO 2 porous ceramics.

[0033] The resulting ZrO 2 The density of porous ceramics is 0.84g / cm 3 , the porosity measured by the Archimedes drainage method is about 86%, the compressive strength is 4.36MPa, and the thermal conductivity at room temperature is 0.075W / (m·K).

Embodiment 3

[0035] According to Example 1, 13.5g of N-MAM, 1.35g of MBAM, 100g of TBA and 15g of isopropanol were uniformly mixed to form a premix solution with a mass fraction of 11.4wt%. Then add 0.38g TEMED, 60g 8YSZ nanopowder, 0.2g sodium hexametaphosphate and 1.3g PVP to the premixed liquid, after ball milling for 1h, add 4g ZrO 2 Hollow spheres, 6g 8YSZ fibers, stirred for 5 minutes and then ultrasonically vibrated for 15 minutes to obtain a stable ceramic slurry suspension. Follow-up steps are carried out according to embodiment 1, obtain ZrO 2 Ceramic foam.

[0036] The resulting ZrO 2 The density of porous ceramics is 0.67g / cm 3 , the porosity measured by the Archimedes drainage method is 88.8%, the compressive strength is 3.02MPa, and the thermal conductivity at room temperature is 0.043W / (m·K).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com