Preparation Technology of Low Melting Point Alloy Semi-solid Melt

A semi-solid, low melting point technology, applied in the field of rheological deformation, can solve the problems of uneven composition of semi-solid melt, difficult cleaning of preparation equipment, poor roundness of crystal nuclei, etc., to improve nucleation efficiency and solve the problem of stirring The problem of dead zone and the effect of good roundness of crystal nucleus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

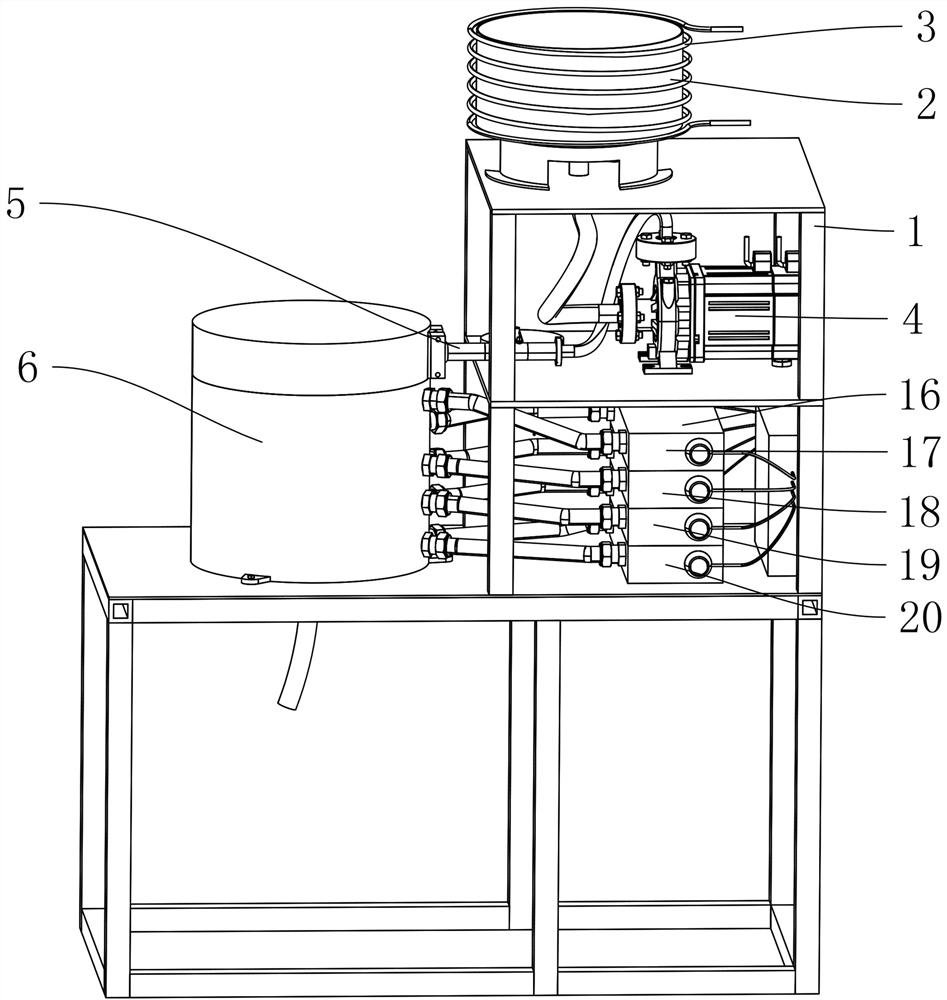

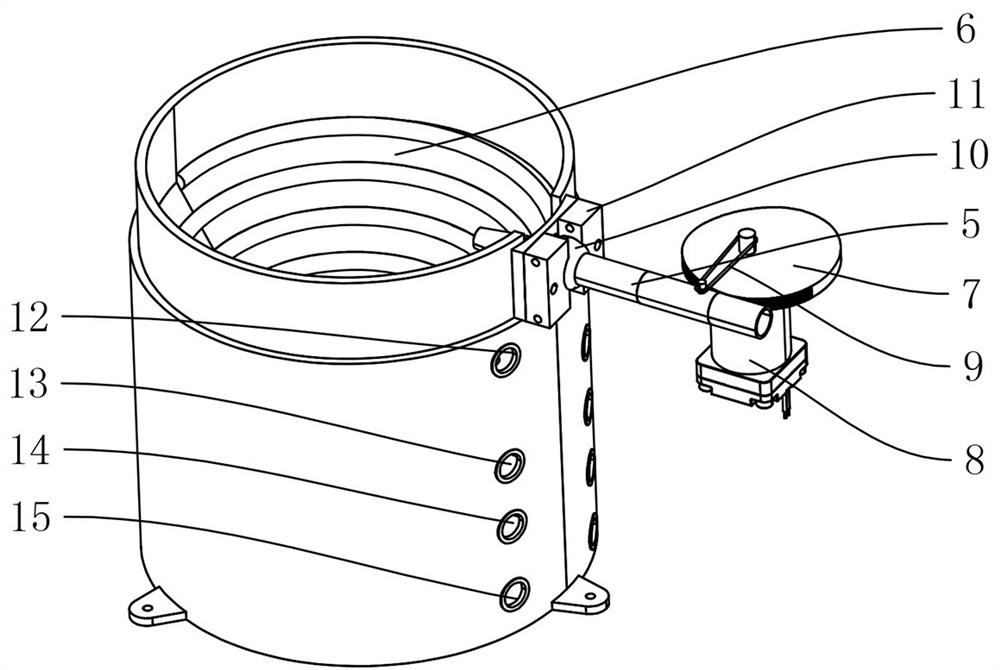

[0019] The present invention is further explained in conjunction with the accompanying drawings.

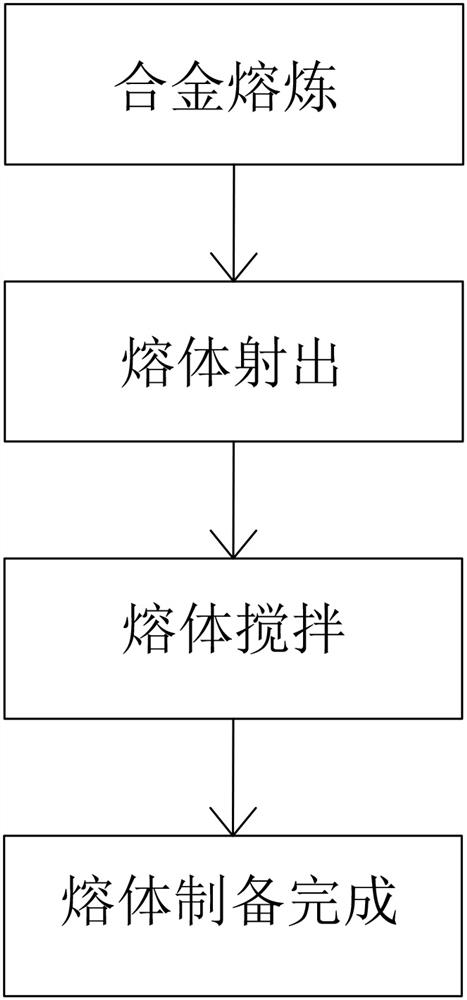

[0020] see Figure 1 to Figure 3 The low-melting-point alloy semi-solid melt preparation process shown includes the following steps:

[0021] a. Alloy smelting: heating and smelting the low-melting point alloy into a semi-solid melt; specifically, placing the low-melting point alloy in the crucible 2, the crucible 2 is set on the frame 1 through the mounting frame, and the heating element 3 is used to heat the The crucible 2 is heated to melt the low melting point alloy in the crucible 2 to form a semi-solid melt. The heating element 3 is an induction coil, and the induction coil is wound around the outer periphery of the crucible 2. By passing an alternating intermediate frequency current into the induction coil, and controlling the current strength by adjusting the frequency, the solid alloy in the crucible 2 generates Vortex, so that the solid alloy heats up and melts; in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com