Method for recycling rare earth minerals from bottom sediments

A seabed sediment and rare earth technology, applied in the direction of process efficiency improvement, solid separation, flotation, etc., to avoid the large consumption of chemicals, reduce the agglomeration of minerals, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

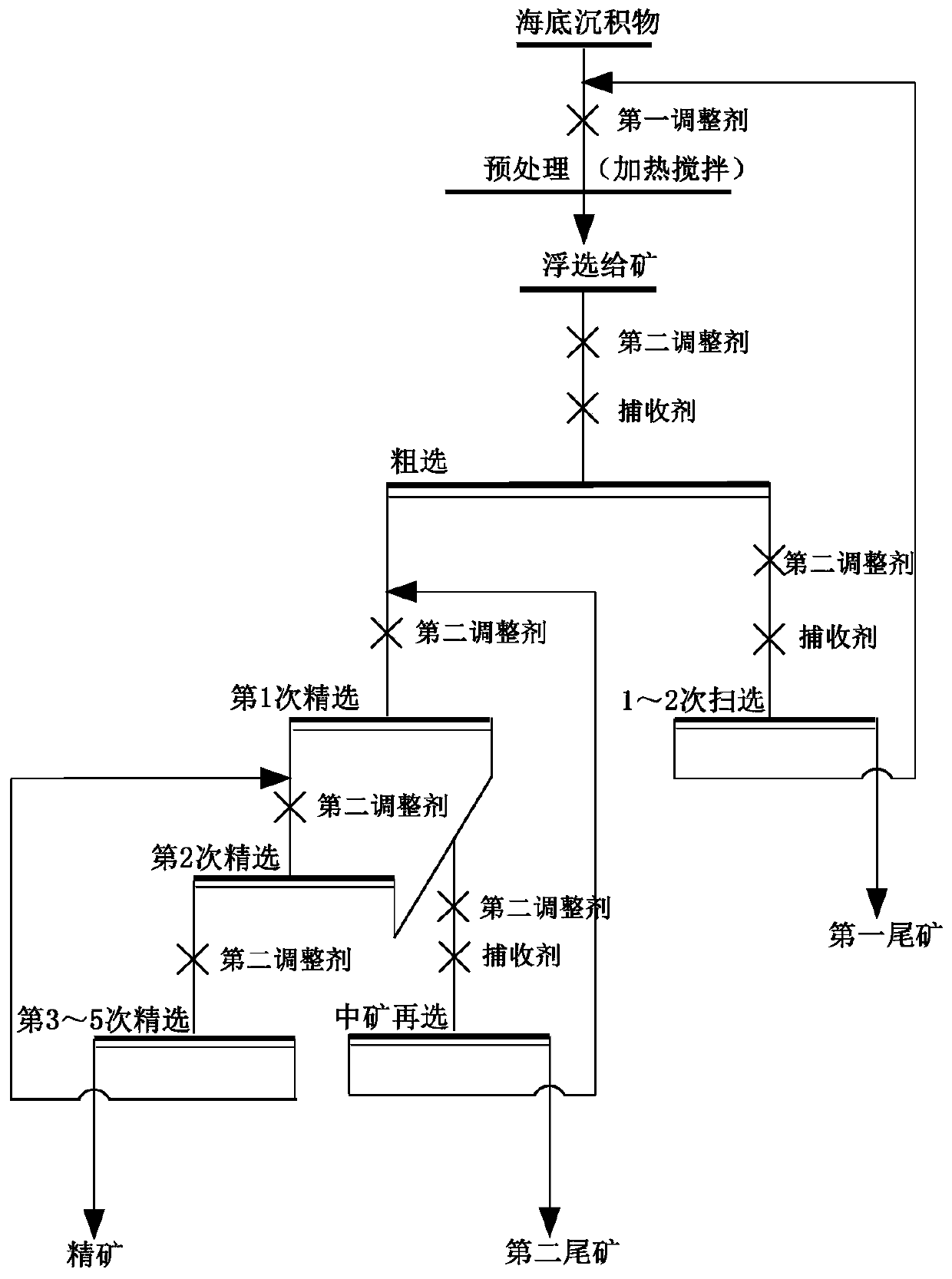

Image

Examples

Embodiment 1

[0085]A method for recovering rare earth minerals from seabed sediments, used for beneficiation and enrichment of rare earth minerals in the seabed sediments, wherein, in this embodiment, the seabed sediments are seabed sediments collected from the central Pacific Ocean, and the The main minerals are illite, feldspar, chlorite, halite and quartz, followed by apatite, iron manganese oxide, calcite, ilmenite, mica, barite, zircon, etc. The average particle size of minerals is 4.5um, the REO content of the ore sample is 0.096%, 50% of the rare earth elements are in apatite, about 40% are in independent rare earth minerals such as monazite and xenotime, and a small amount is distributed in iron manganese oxides and clay minerals.

[0086] Methods for recovering rare earth minerals from seabed sediments specifically include:

[0087] S1. Pretreatment operation. The pretreatment operation includes: mixing the seabed sediment at 60° C. with the first regulator under the action of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com