PTFE composite film for MABR, and preparation method thereof

A composite membrane and tubular membrane technology, which is applied in chemical instruments and methods, membrane, membrane technology, etc., can solve the problems of poor affinity, unfavorable stable attachment and growth of microorganisms, poor microbial affinity, etc., and achieve stable physical and chemical properties, excellent Microbial affinity performance, long-term stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

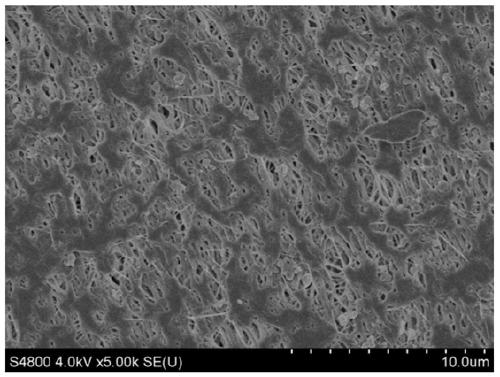

Embodiment 1

[0020] In step (1), select a PTFE flat membrane with a thickness of 10 microns and an average pore size of 0.2 microns, and carry out hydrophilic modification through (hydroxyethyl methacrylate and methylol acrylamide) prepolymerization solutions in sequence to obtain a hydrophilic The PTFE flat membrane; the test results show that the initial instantaneous water droplet contact angle of the PTFE flat membrane is 55°, which can be reduced to 0° within 20 seconds.

[0021] Step (2), cutting the hydrophilic modified PTFE flat microporous membrane to obtain a strip-shaped PTFE flat microporous membrane with a width of 10 mm;

[0022] Step (3), select a polytetrafluoroethylene hollow fiber tube membrane with an outer diameter of 3 mm, a tube wall of 0.5 mm, an average pore size of 1 micron, a tensile breaking force of 90 N, and a water droplet contact angle of 145°, and the step ( 2) The strip-shaped PTFE flat membrane obtained is wrapped on its surface at an angle of 45 °, and is...

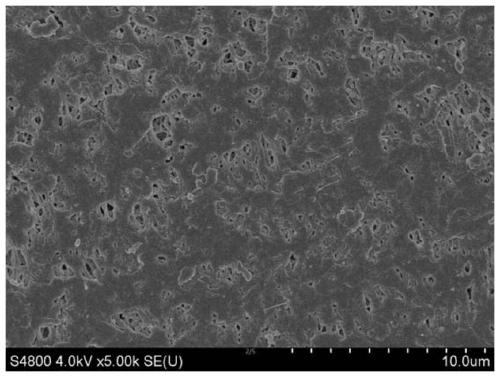

Embodiment 2

[0026] Step (1), select a PTFE flat membrane with a thickness of 20 microns and an average pore size of 0.1 microns, and carry out hydrophilic modification through (N-vinylpyrrolidone and vinyltriethoxysilane) prepolymerization solution to obtain hydrophilic The PTFE flat membrane; the test results show that the initial instantaneous water droplet contact angle of the PTFE flat membrane is 35°, which can be reduced to 0° within 10 seconds.

[0027] Step (2), cutting the hydrophilic modified PTFE flat microporous membrane to obtain a strip-shaped PTFE flat microporous membrane with a width of 20 mm;

[0028] In step (3), select a polypropylene hollow fiber tube membrane with an outer diameter of 4 mm, a tube wall of 1 mm, an average pore size of 2.5 microns, a tensile strength of 10 MPa, and a water droplet contact angle of 130°, and obtain from step (2) The strip-shaped PTFE flat membrane is wrapped on its surface at an angle of 30°, and is continuously welded at room temperat...

Embodiment 3

[0031] Step (1), select a PTFE flat membrane with a thickness of 5 microns and an average pore diameter of 0.3 microns, and carry out hydrophilic modification through (acrylic acid and vinyltrimethoxysilane) prepolymerization solution to obtain a hydrophilic PTFE flat membrane; The test results show that the initial instantaneous water droplet contact angle of the PTFE flat membrane is 60°, which can be reduced to 0° within 30 seconds.

[0032] Step (2), cutting the hydrophilic modified PTFE flat microporous membrane to obtain a strip-shaped PTFE flat microporous membrane with a width of 30 mm;

[0033]In step (3), select a polyethylene hollow fiber tube membrane with an outer diameter of 2 mm, a tube wall of 0.1 mm, an average pore size of 0.5 microns, a tensile strength of 7 MPa, and a water droplet contact angle of 130°, and obtain from step (2) The strip-shaped PTFE flat membrane is wrapped on its surface at an angle of 55°, and is continuously welded at room temperature t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com