Method and equipment for treating VOCs by utilizing flue gas

A flue gas treatment and gas technology, applied in the field of using flue gas to treat VOCs gas, can solve the problems of long construction period, large equipment volume, large energy consumption, etc., and achieve the effect of simple method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

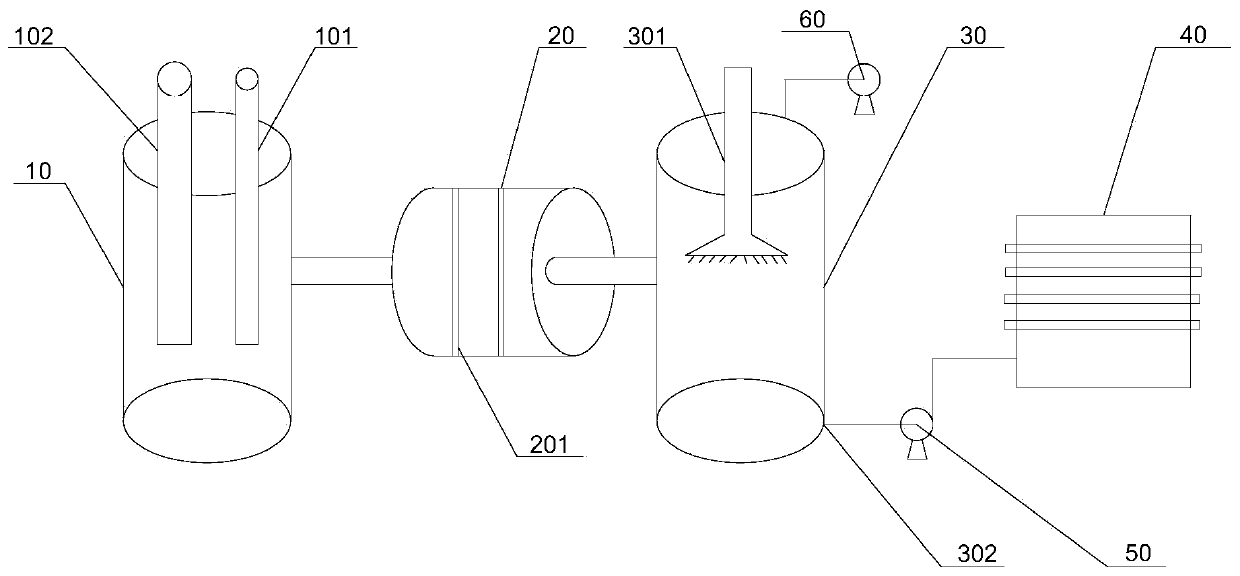

[0063] refer to figure 1 As shown, the top inlet of pre-reaction tank 10 is provided with cupola flue gas pipeline 101 and incinerator flue gas pipeline 102 side by side, and the diameter of incinerator flue gas pipeline 102 is 2 times of cupola flue gas pipeline 101 diameters, two times Two pipes extend into the pre-reaction tank 10 at the same time, so that the cupola flue gas and the incineration solidification furnace flue gas enter the pre-reaction tank 10 with a volume ratio of 1:2 and fully mix, and chemical reactions occur, and sulfur dioxide is respectively mixed with formaldehyde, Phenol and methane total hydrocarbons react to generate respectively hydroxymethanesulfonic acid, carbolic acid (acid) and sodium sulfite and carbon dioxide, nitrogen, nitric oxide, nitrogen dioxide and methane total hydrocarbons to generate nitrogen and water respectively, and the cross-sectional area of the pre-reaction tank 10 It is twice the sum of the cross-sectional areas of the cup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com