A kind of graphite felt composite electrode and preparation method thereof

A composite electrode and graphite felt technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of low specific surface area, low electrocatalytic activity, poor electrochemical reactivity, etc., and achieve mild reaction conditions, process and operation The steps are simple and the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A graphite felt composite electrode and a preparation method thereof, the steps of the preparation method are as follows:

[0032] s1. Pretreatment of graphite felt electrodes: put dry and clean graphite felt electrodes into a tube furnace, heat them at 500°C for 10 hours under air conditions, and take them out after natural cooling;

[0033] The graphite felt electrode is a polyacrylonitrile-based graphite felt electrode, which is prepared by the following method: the commercially available polyacrylonitrile-based graphite felt is made into a cube block with a size of 30×30×4.6 mm, rinsed three times with deionized water, Then put it into an appropriate amount of ethanol solution and ultrasonically clean it at a frequency of 90 kHz for 60 minutes, then rinse it with a large amount of deionized water for 3 times, and finally put the graphite felt in a constant temperature drying oven and dry it at 80°C for 6 hours to obtain a dry and clean graphite felt electrode;

[00...

Embodiment 2

[0037] The technical scheme of this embodiment is basically the same as that of Embodiment 1, and the only difference is that in the last step of step s3, the graphite felt electrode modified by the carboxylated carbon nanotube-polydopamine composite after cleaning and drying is placed in a tube furnace, at a temperature of It is obtained by carbonization treatment under vacuum conditions at 900°C for 5 hours.

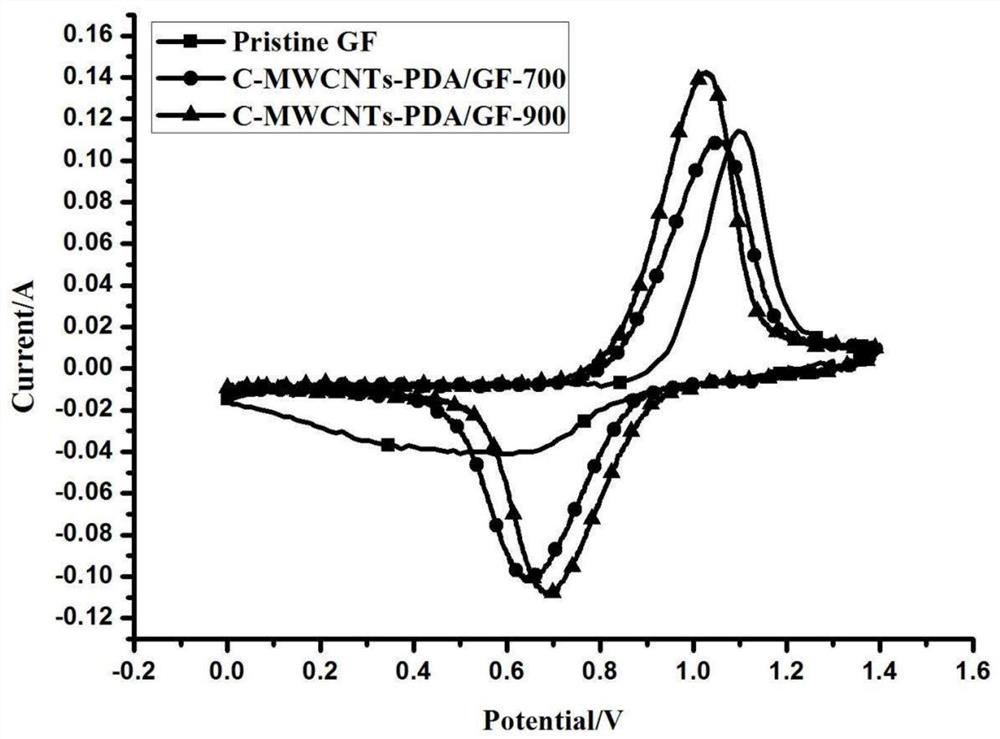

[0038] figure 1 It is the cyclic volt curve diagram of embodiment one, embodiment two and the original graphite felt electrode of the present invention, depicts the original graphite felt electrode, the graphite felt electrode prepared by embodiment one and the graphite felt electrode prepared by embodiment two at 0-1.4V , the cyclic voltammetry curve in the range of 5mV / s, wherein Pristine GF represents the original graphite felt electrode, C-MWCNTs-PDA / GF-700 represents the graphite felt composite electrode that was carbonized at 700°C in Example 1, and C-MWCNTs-PDA / ...

Embodiment 3

[0041] A graphite felt composite electrode and a preparation method thereof, the steps of the preparation method are as follows:

[0042] s1. Pretreatment of graphite felt electrodes: Put the dry and clean graphite felt electrodes into a tube furnace, heat them at 400°C for 9 hours under air conditions, and take them out after natural cooling;

[0043] s2. Preparation of carboxylated carbon nanotube-polydopamine composite: Mix carboxylated carbon nanotubes dispersed in deionized water with ultrasonic oscillation and dopamine to obtain a mixed solution, wherein the mass ratio range of carboxylated carbon nanotubes to dopamine is 4:8; while stirring, slowly add Tris-HCL buffer solution to the mixed solution to adjust the pH of the mixed solution to pH=8.0, so that dopamine undergoes self-polymerization reaction at room temperature, and the obtained carboxylated multi-walled carbon nanotube-polymer The dopamine complex is then vacuum filtered and dried, and taken out after natura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com