Wool fabric anti-felting finishing method with high-strength retention rate

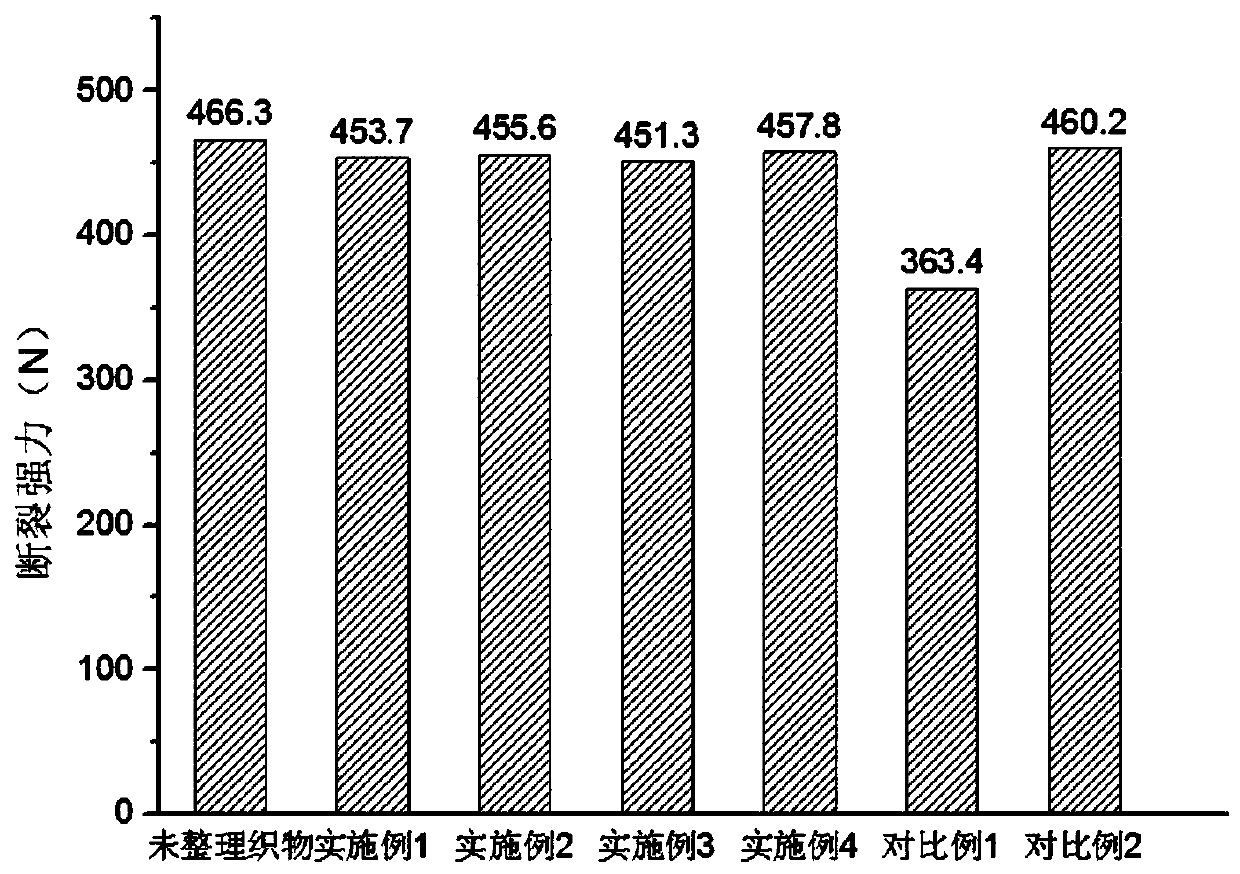

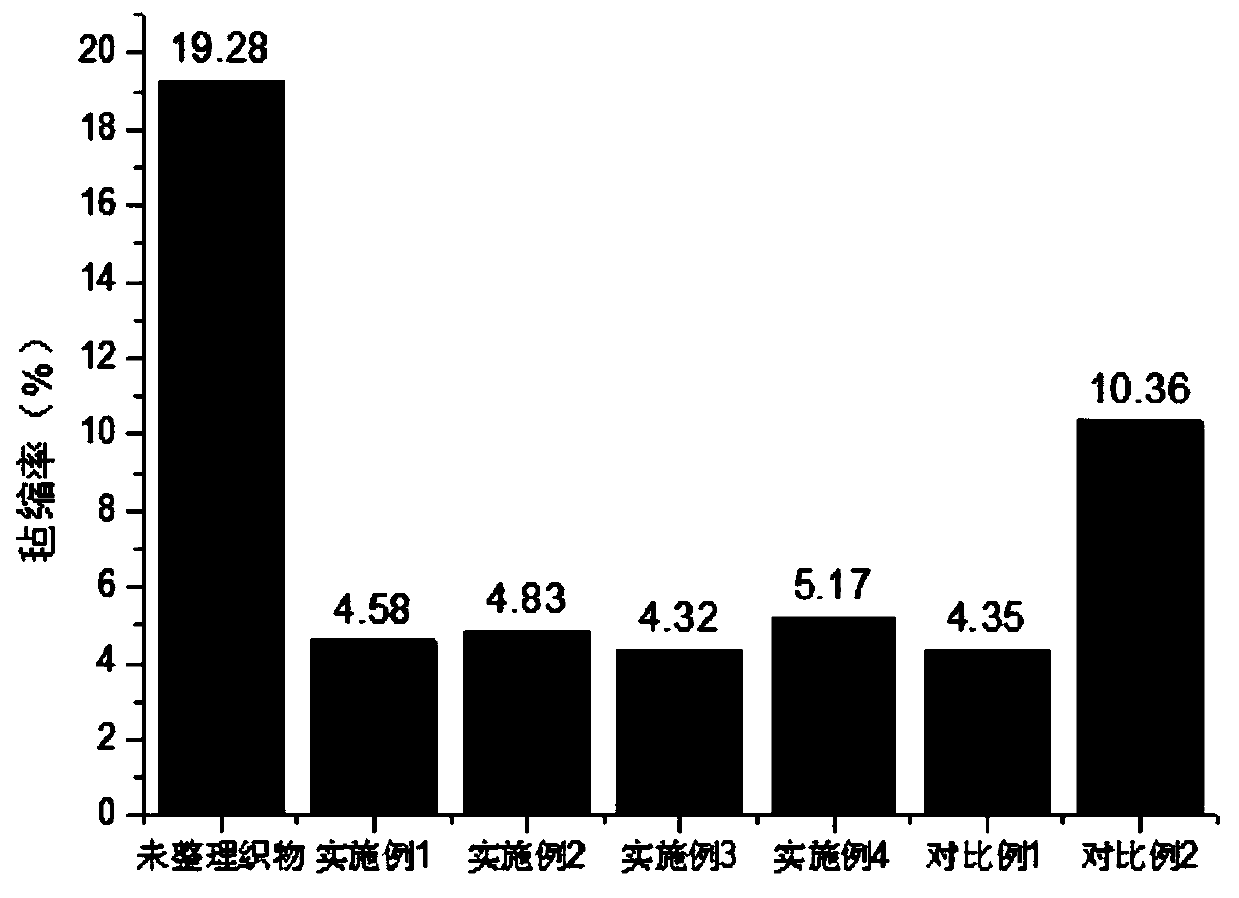

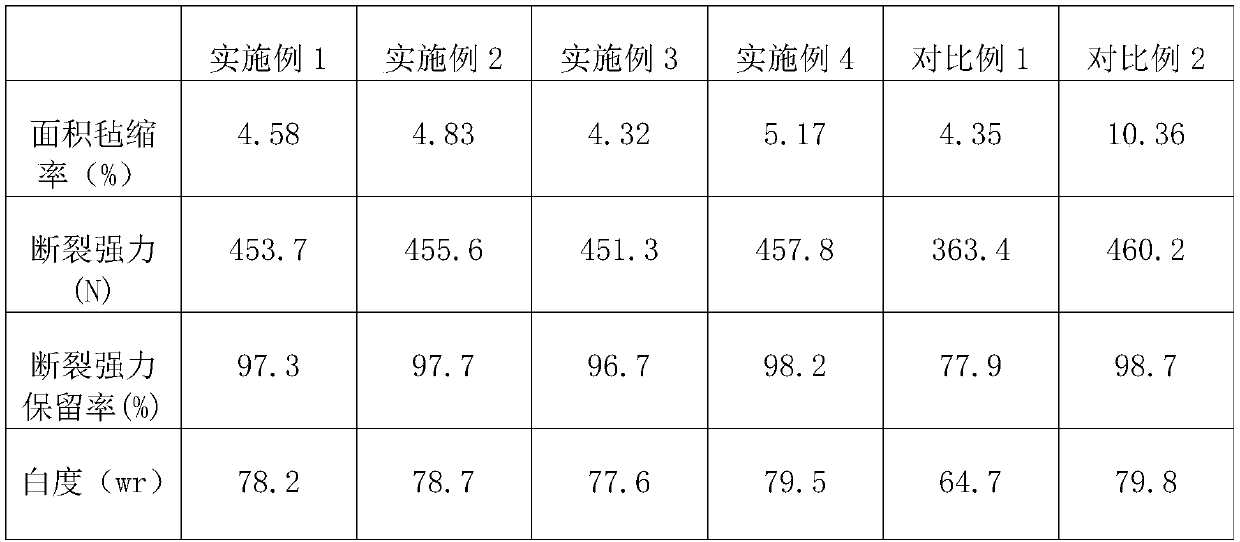

A high-strength, high-retention technology, applied in shrink-resistant fibers, enzyme/microbial biochemical treatment, fiber treatment, etc., can solve the problems of reducing the mechanical strength of wool fabrics and destroying the structure of wool fibers, so as to improve wearability, The effect of promoting enzymatic hydrolysis and improving breaking strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The high-strength retention rate anti-felting finishing method for wool fabrics comprises the following steps:

[0032] 1) According to the bath ratio of 1:30, put the wool fabric into the hydrogen peroxide treatment solution for oxidation treatment for 30 minutes. The hydrogen peroxide treatment solution includes the following components in proportion by mass percentage: hydrogen peroxide 15%, sodium pyrophosphate 5%, and The amount is water; take it out and fully wash it with water, and dry it at room temperature to obtain wool fabric a;

[0033] 2) adding epoxypropyl dodecyl diethyl ammonium chloride to deionized water and stirring and dissolving to prepare a mass concentration of 4% epoxy propyl dodecyl diethyl ammonium chloride solution, and step 1 ) in active wool fabric according to the bath ratio of 1:20 into the epoxy propyl dodecyl diethyl ammonium chloride solution, warming up to 50 ° C, heat preservation reaction 8h, the wool fabric is placed in an oven at 5...

Embodiment 2

[0037] The high-strength retention rate anti-felting finishing method for wool fabrics comprises the following steps:

[0038] 1) According to the bath ratio of 1:30, put the wool fabric into the hydrogen peroxide treatment solution for oxidation treatment for 30 minutes. The hydrogen peroxide treatment solution includes the following components in proportion by mass percentage: hydrogen peroxide 15%, sodium pyrophosphate 5%, and The amount is water; take it out and fully wash it with water, and dry it at room temperature to obtain wool fabric a;

[0039] 2) adding epoxypropyl dodecyl diethyl ammonium chloride to deionized water and stirring and dissolving to prepare a mass concentration of 1% epoxy propyl dodecyl diethyl ammonium chloride solution, and step 1 ) in active wool fabric according to the bath ratio of 1:20 into the epoxy propyl dodecyl diethyl ammonium chloride solution, warming up to 40 ° C, heat preservation reaction 6h, the wool fabric is placed in an oven at 5...

Embodiment 3

[0043] The high-strength retention rate anti-felting finishing method for wool fabrics comprises the following steps:

[0044] 1) According to the bath ratio of 1:30, put the wool fabric into the hydrogen peroxide treatment solution for oxidation treatment for 30 minutes. The hydrogen peroxide treatment solution includes the following components in proportion by mass percentage: hydrogen peroxide 15%, sodium pyrophosphate 5%, and The amount is water; take it out and fully wash it with water, and dry it at room temperature to obtain wool fabric a;

[0045] 2) adding glycidyl dodecyl diethyl ammonium chloride to deionized water and stirring and dissolving to prepare a mass concentration of 5% glycidyl dodecyl diethyl ammonium chloride solution, and step 1 ) in the active wool fabric according to the bath ratio of 1:20 into the glycidyl dodecyl diethylammonium chloride solution, warming up to 45 ° C, heat preservation reaction 10h, the wool fabric is placed in an oven at 50 ° C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com